Method of manufacturing analysis specimen

A sample and powder technology, which is applied in the field of production of analytical samples, can solve the problems of contamination of analytical samples, difficulty in grinding, and difficulty in removing the surface of samples, and achieve the effect of inhibiting oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

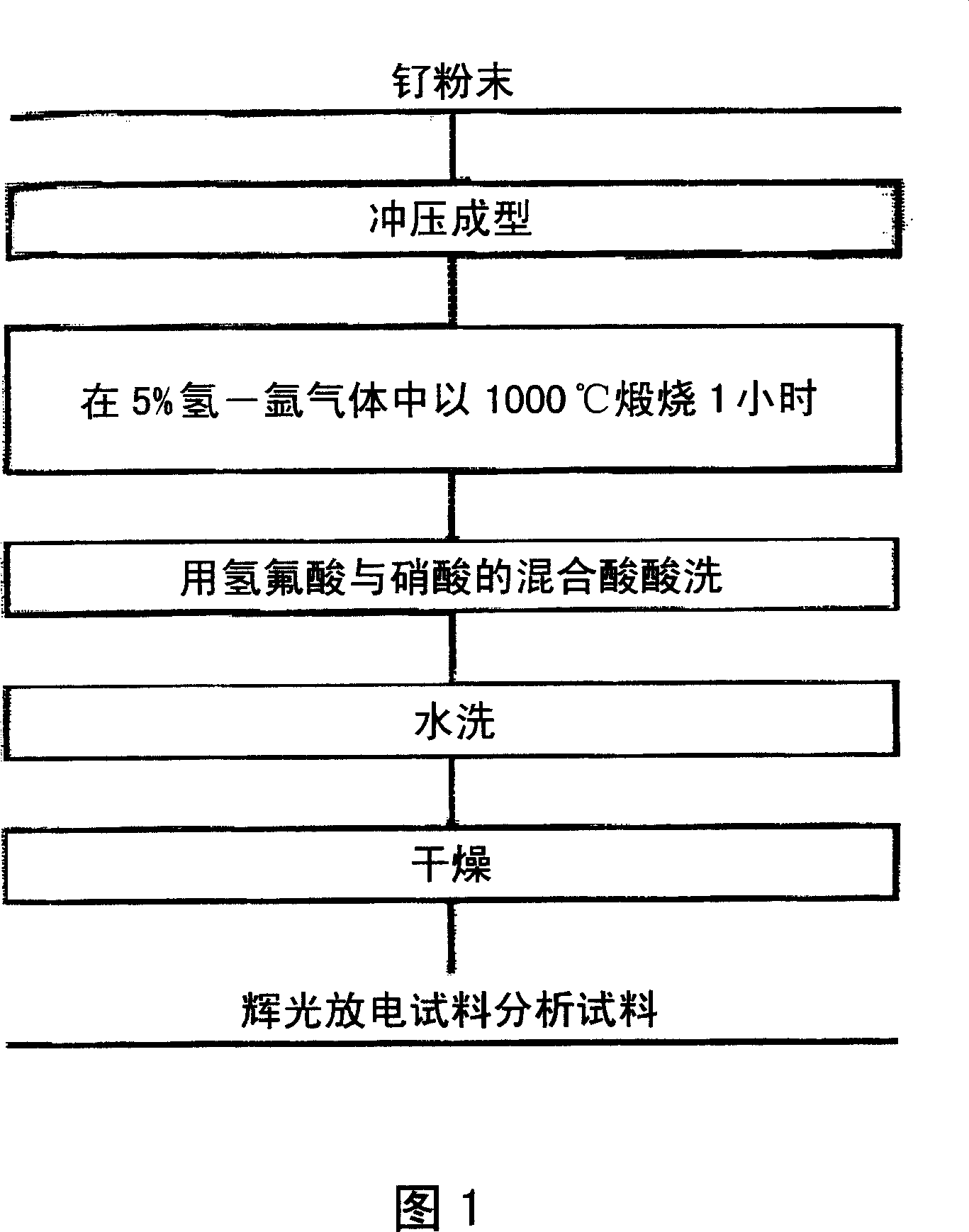

[0030] Examples of the present invention are described below. Example 1 will be described with the flowchart shown in FIG. 1 .

[0031] Ruthenium powder is produced by the following method.

[0032] Sodium bromate is added to an aqueous solution of platinum group metals using copper electrolytic precipitates as a raw material to distill ruthenium into volatile ruthenium tetroxide and recover as ruthenium chloride in a 6 mol / L hydrochloric acid solution.

[0033] Add ammonium chloride to 7 liters of the hydrochloric acid solution containing the ruthenium chloride, heat at 90°C for 2 hours and let it cool to room temperature, filter the crystallized ammonium hexachlororuthenium (hexachlororuthenium) with filter paper, put high-purity alumina The obtained container was kept at 600° C. for 2 hours in a nitrogen atmosphere with a tubular furnace, and the first-stage calcination was performed to obtain sponge-like (sponge) crude ruthenium. It is crushed with a mortar to obtain rut...

Embodiment 2

[0039] In Example 2, ruthenium powder was molded with a mold made of yttrium-stabilized zirconia, and a sample was produced in the same manner as in Example 1, except that pure hydrogen was used in the atmosphere during sintering. There was no discoloration on the surface of the analysis sample after sintering. When measured by glow discharge mass spectrometry, zirconium (atomic number 40) and yttrium (atomic number 39) were less than 1 mass ppm, so that the analytical values substantially the same as in Example 1 were obtained. (refer to Table 2)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moh's hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com