Method for preparing monodisperse, non agglomerate Nano zinc oxide with high ultraviolet absorption

A nano-zinc oxide, monodisperse technology, used in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of decreased purity, uneven powder particle size, uneven dispersion, etc., and achieve good crystallinity , good uniformity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

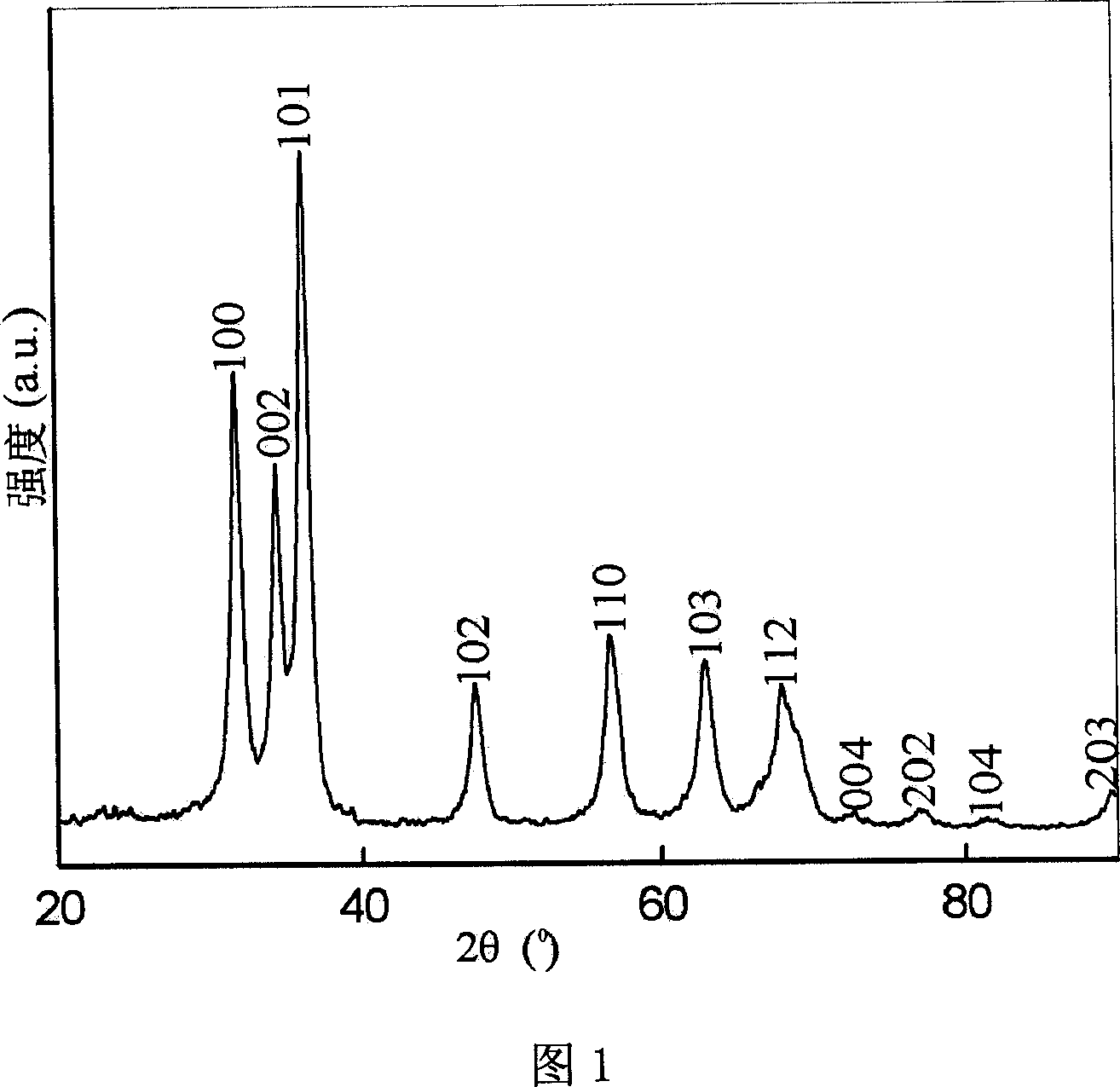

Embodiment 1

[0028] 14.875g of zinc nitrate and 9.6g of ammonium carbonate were respectively dissolved in a mixed solvent composed of 150ml of absolute ethanol and 50ml of deionized water, and stirred evenly. Then adopt the reverse titration method, under vigorous stirring, gradually add the zinc nitrate solution to the ammonium carbonate solution dropwise, after the dropwise addition is completed, gradually raise the temperature to 60°C, and react at a constant temperature of 60°C for 1 hour under high-speed stirring. After cooling to room temperature, the white precipitate was obtained by suction filtration, which was washed 4-5 times with deionized water and absolute ethanol. After suction filtration, the obtained filter cake was dried in a vacuum drying oven at a drying temperature of 60° C. and a drying time of 12 hours. The dried precipitate was calcined in a muffle furnace at a temperature of 300° C. for 2 hours, and finally A monodisperse and non-agglomerated nano-zinc oxide white ...

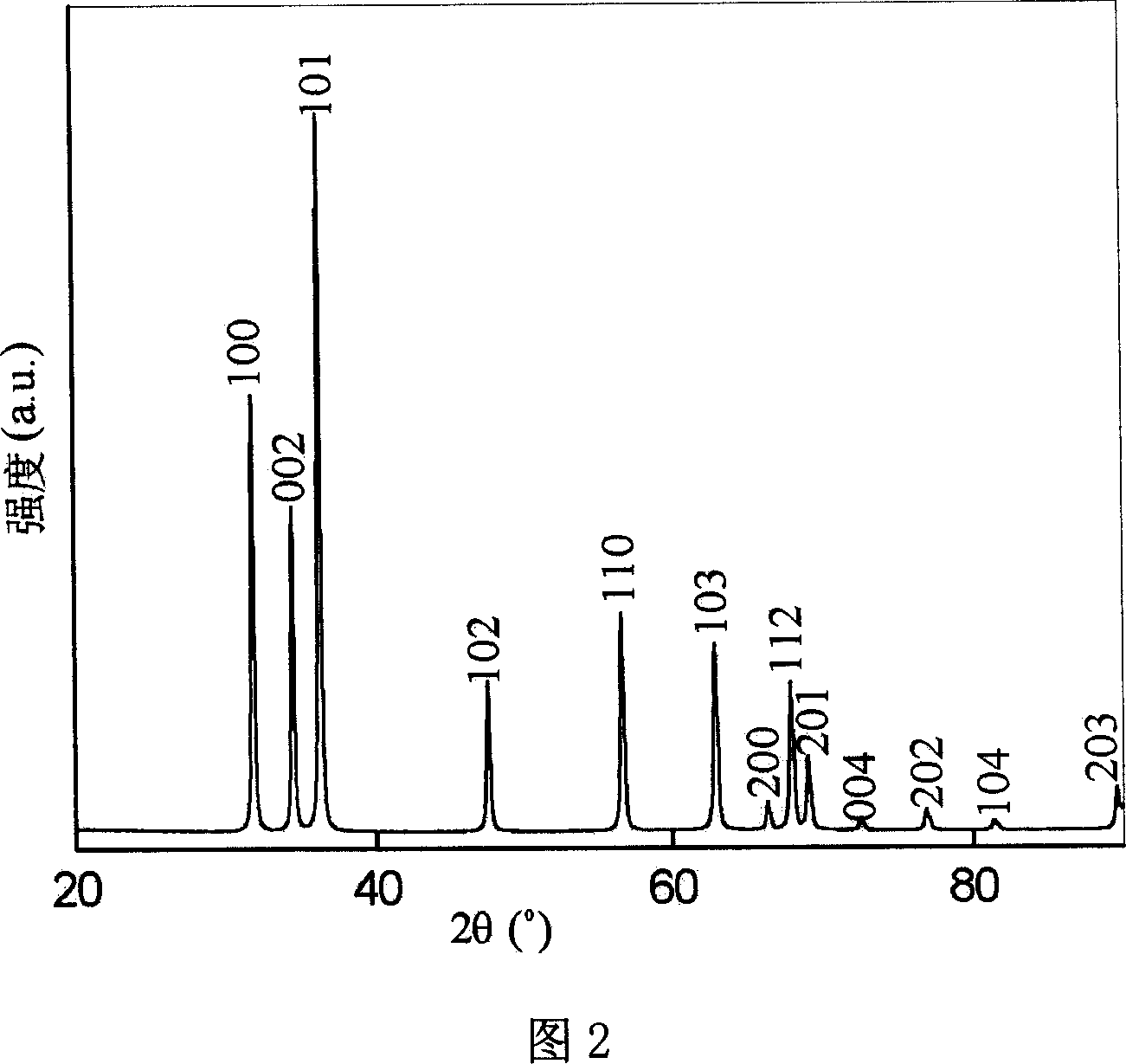

Embodiment 2

[0033]14.875g of zinc nitrate and 9.6g of ammonium carbonate were respectively dissolved in a mixed solvent composed of 50ml of absolute ethanol and 50ml of deionized water, and stirred evenly. Then adopt the reverse titration method, under vigorous stirring, gradually add the zinc nitrate solution to the ammonium carbonate solution dropwise, after the dropwise addition is completed, gradually raise the temperature to 60°C, and react at a constant temperature of 60°C for 1 hour under high-speed stirring. After cooling to room temperature, the white precipitate was obtained by suction filtration, which was washed 4-5 times with deionized water and absolute ethanol. After suction filtration, the obtained filter cake was dried in a vacuum oven at a drying temperature of 60° C. and a drying time of 10 hours. The dried precipitate was calcined in a muffle furnace at a temperature of 300° C. for 2 hours, and finally A monodisperse and non-agglomerated nano-zinc oxide white powder is...

Embodiment 3

[0038] 16.1 g of anhydrous zinc sulfate and 16.0 g of ammonium bicarbonate were respectively dissolved in a mixed solvent composed of 250 ml of absolute ethanol and 250 ml of deionized water, and stirred evenly. Then use the reverse titration method, under vigorous stirring, add the zinc nitrate solution to the ammonium bicarbonate solution, after the dropwise addition is completed, gradually raise the temperature to 60°C, and react at a constant temperature of 60°C for 1 hour under high-speed stirring. After cooling to room temperature, the white precipitate was obtained by suction filtration, which was washed 4-5 times with deionized water and absolute ethanol. After suction filtration, the obtained filter cake was dried in an electric heating constant temperature blast drying oven, the drying temperature was 60° C., and the drying time was 24 hours. The dried precipitate was calcined in a muffle furnace at 350° C. for 2 hours; finally a monodisperse white nano-zinc oxide po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com