Aluminum-silicon alloy alterative and manufacturing method thereof

A technology of aluminum-silicon alloy and modifier, applied in the field of aluminum-silicon alloy modifier and its preparation, can solve the problems of increased aluminum consumption, easy segregation, large amount of reaction slag, etc., and achieves precise control of addition amount, simple modification process, and phosphorus absorption. rate stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

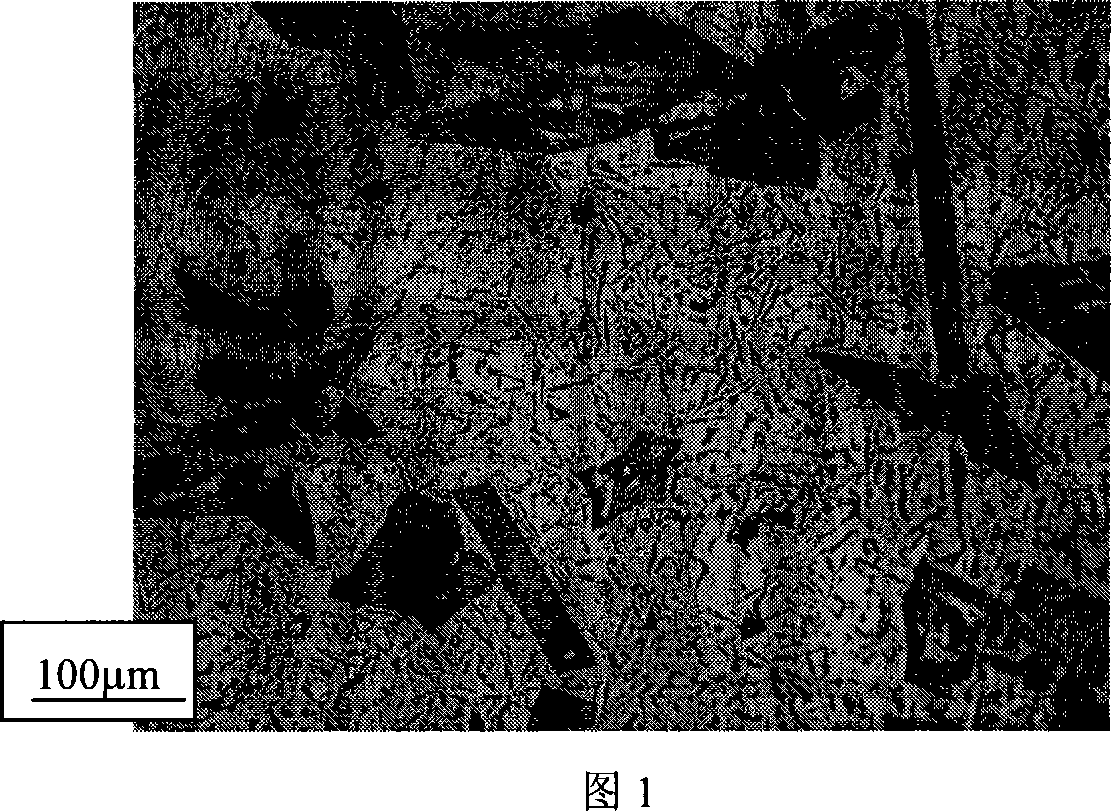

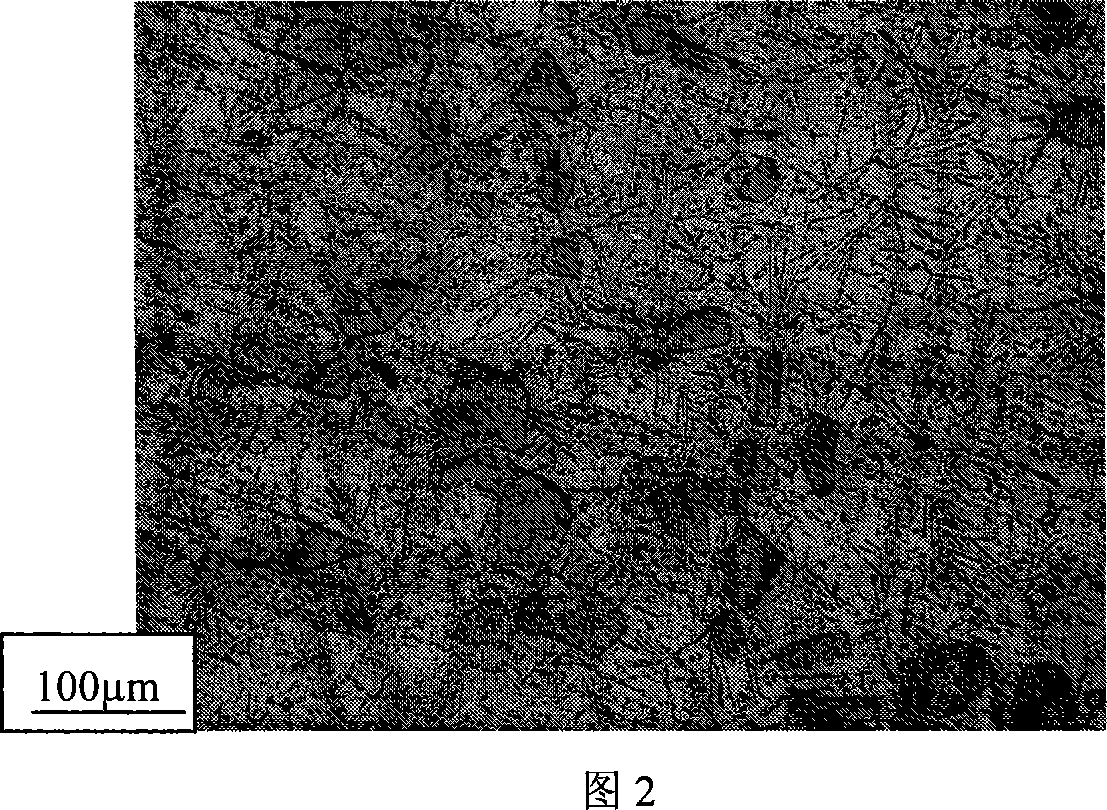

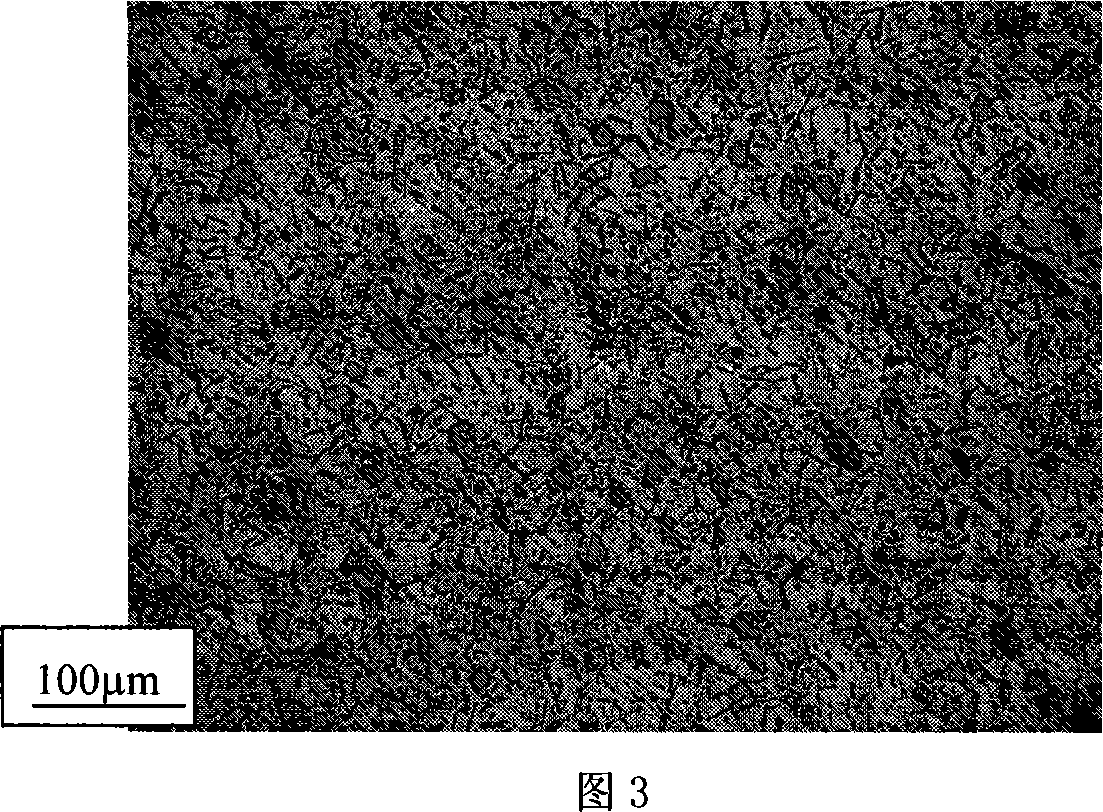

Image

Examples

Embodiment 1

[0023] (1) The mass percent composition of the modificator is phosphorus: 2%, titanium: 3%, carbon: 0.15%, and the balance is aluminum. (2) Weigh 20% red scale and 80% aluminum powder by weight, mix them evenly, and briquette them under a pressure of 1kN. (3) Put the briquette into a self-made vacuum self-propagating reactor, and use an iron-chromium-aluminum resistance wire as an ignition coil. 200s after ignition, the reaction is complete. (4) After crushing the aluminum-phosphorus alloy prepared in step 3 in a jaw crusher, put it into an ordinary ball mill for ball milling for 0.5-1 hour. Take the powder under 100 mesh sieve, and briquette again under the pressure of 1kN. (5) Titanium: 3% and carbon: 0.15% according to mass percentage of modificator, weigh activated carbon and potassium fluorotitanate powder, mix uniformly and briquette under 1kN pressure. (6) Weigh commercially pure aluminum, heat and melt it, add activated carbon and potassium fluorotitanate mixed powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com