Method for preparing Ce-Zr based nano rare earth composite oxide

A composite oxide and nano-composite technology, applied in the fields of material chemistry and environmental chemistry, can solve the problems of small fresh specific surface area, weak aging resistance, high production cost, etc., and achieve no waste liquid discharge, low cost and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

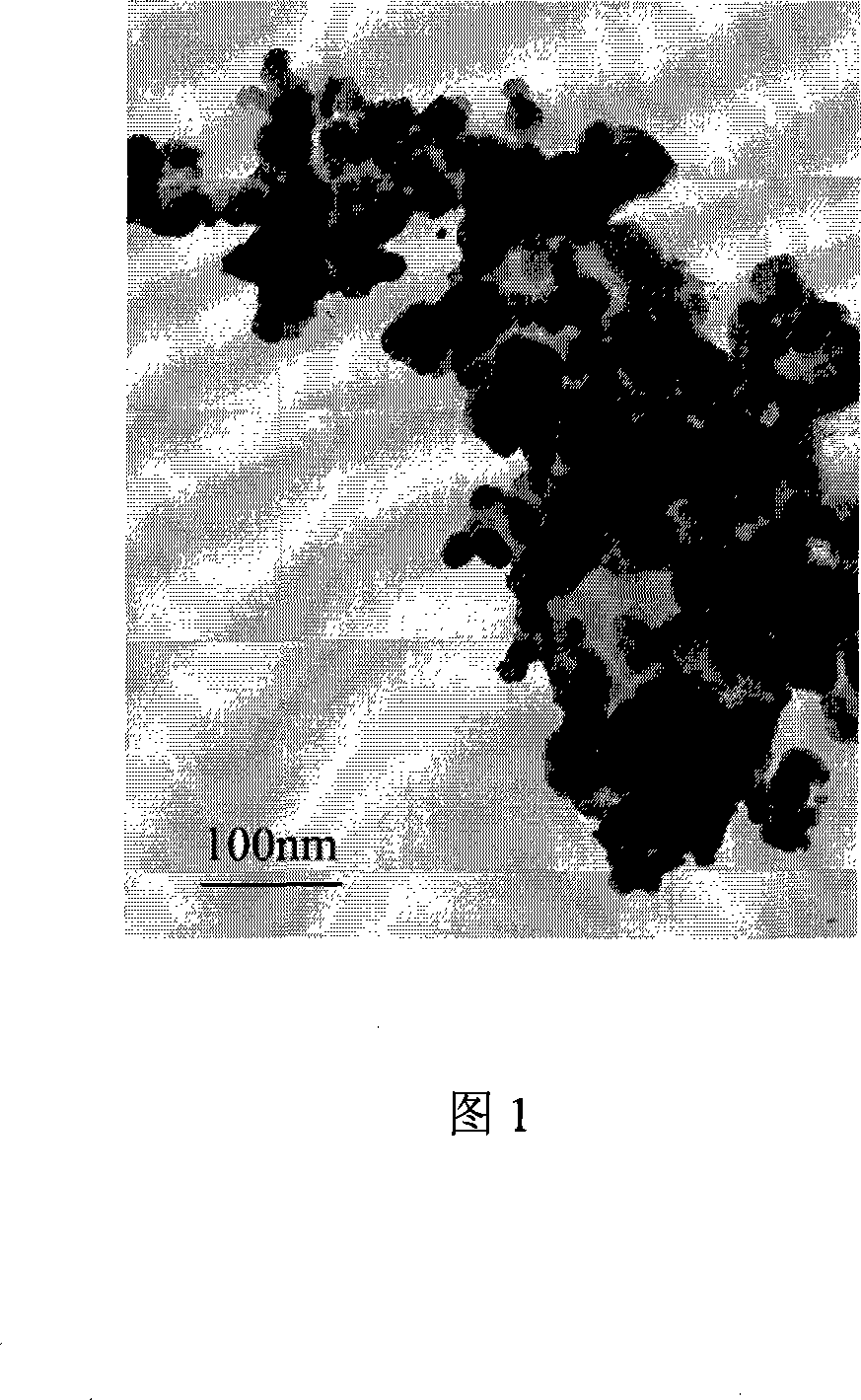

Image

Examples

Embodiment 1

[0027] The weight ratio of each component in the target product cerium-zirconium-based nano-rare earth composite oxide is: CeO 2 65% ZrO 2 20%, LaO 2 15% according to CeO 2 , ZrO 2 Weigh 161g of low-chloride cerium carbonate and 44g of low-chloride zirconium carbonate required for the reaction, add 22g of oxalic acid therein, and keep grinding and stirring, the dry powder gradually changes from dry white powder to white viscous. Weigh 15g of lanthanum oxide and mix it into the above system, stir well, add 50g of surfactant Triton-100, and stir evenly. After drying at 90°C for 6 hours, the precursor of the target product was obtained. After the precursor is ground, it is transferred into a crucible and placed in a muffle furnace. Calcined at 550°C for 2 hours, took out the crucible, cooled naturally, crushed with a jet mill or ball milled to obtain the desired product. The fresh specific surface area of the measured product is 130m 2 / g, the specific surface area after...

Embodiment 2

[0029] According to the weight ratio of each component of the target product: CeO 2 45%, ZrO 2 50%, YO 2 The proportion of 5% is used for product preparation. Weigh 111g of low-chloride cerium carbonate, weigh 111g of low-chloride zirconium carbonate, add 40g of citric acid to it, and keep grinding and stirring, the dry powder gradually changes from dry white powder to white viscous. Weigh 5g of yttrium oxide, mix it into the above system, stir well, add 24g of polyethylene glycol, and stir evenly. After drying at 90°C for 6 hours, the precursor of the target product was obtained. After the precursor is ground, it is transferred into a crucible and placed in a muffle furnace. Calcined at 450°C for 2 hours, took out the crucible, cooled naturally, and pulverized or ball milled with a jet mill to obtain the desired product. Determination of the fresh specific surface area of the product is 100m 2 / g, the specific surface area after sintering at 900°C for 2h is 45m 2 / g....

Embodiment 3

[0031] According to the weight ratio of each component of the target product: CeO 280% ZrO 2 15% NdO 2 The proportion of 5% is used for product preparation. Weigh 198g of low-chloride cerium carbonate, weigh 33g of low-chloride zirconium carbonate, add 20g of formic acid to it, grind and stir continuously, the dry powder gradually changes from dry white powder to white viscous. Weigh 5 g of yttrium oxide and mix it into the above system, stir well, add 19 g of Tween, and stir evenly. After drying at 90°C for 6 hours, the precursor of the target product was obtained. After the precursor is ground, it is transferred into a crucible and placed in a muffle furnace. Calcined at 650°C for 2 hours, took out the crucible, cooled naturally, and pulverized or ball milled with a jet mill to obtain the desired product. Determination of the fresh specific surface area of the resulting product is 100m 2 / g, the specific surface area after sintering at 900°C for 2h is 55m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com