Method of producing sorbic alcohol and mannitol by utilizing cellulose

A cellulose and sorbitol technology, applied in organic chemistry, hydrolysis preparation and other directions, can solve the problems of inevitable equipment corrosion, increased equipment investment cost, low reaction efficiency, etc., and achieves a small investment, low equipment requirements, and simple reaction system. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1, hydrolyzing cellulose to produce sorbitol and mannitol

[0016] 1g of microcrystalline cellulose (microcrystalline cellulose, available from Alfa Aesar) was placed in a 150ml reactor filled with sufficient water (50ml), 0.4g of Pd / C catalyst was added, and filled with H 2 , the pressure in the reactor was 60atm, heated to 290°C, and reacted for 1 hour.

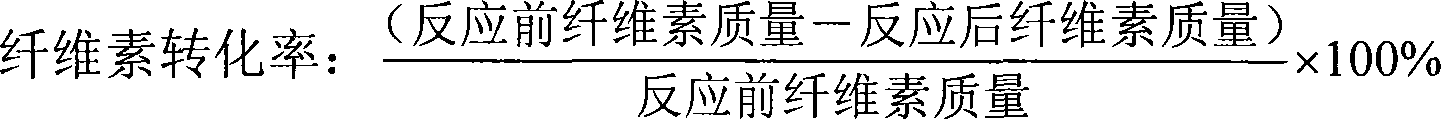

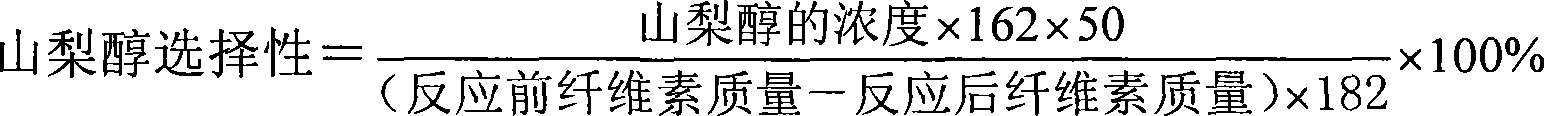

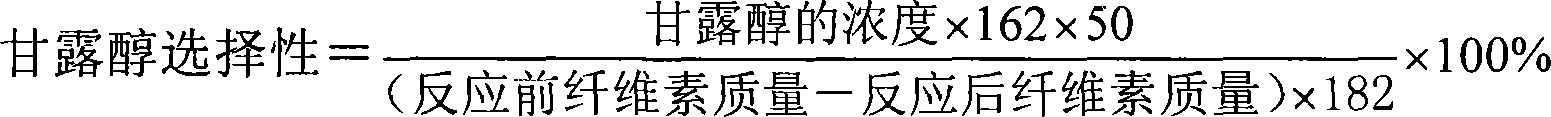

[0017] According to the following method, the conversion rate of cellulose and the productive rate of sorbitol and mannitol are detected:

[0018] Reaction product is carried out mass spectrometry, and the result shows, mass spectrometry gives the molecular ion peak that mass-to-charge ratio is 183, provides the molecular ion peak of mass-to-charge ratio 183 molecular weight on mass spectrum with the standard sample of sorbitol and mannitol coincides; The reaction product is carried out High-performance liquid phase analysis and quantification, (Agilent 1100Series HPLC, purchased by Beijing Agilent Co., L...

Embodiment 2

[0026] Embodiment 2, hydrolyzing cellulose to produce sorbitol and mannitol

[0027] 1g of natural cellulose (purchased from Beijing Reagent Company) was placed in a 150ml reaction kettle filled with sufficient water (50ml), added 0.1g of Pt / C catalyst, charged with H 2 , the pressure in the reactor was 60atm, heated to 220°C, and reacted for 2 hours.

[0028] According to the following method, the conversion rate of cellulose and the productive rate of sorbitol and mannitol are detected:

[0029] Reaction product is carried out mass spectrometry, and the result shows, mass spectrometry gives the molecular ion peak that mass-to-charge ratio is 183, provides the molecular ion peak of mass-to-charge ratio 183 molecular weight on mass spectrum with the standard sample of sorbitol and mannitol coincides; The reaction product is carried out High-performance liquid phase analysis and quantification, (Agilent 1100Series HPLC, purchased by Beijing Agilent Co., Ltd., separation column...

Embodiment 3

[0031] Embodiment 3, hydrolyzing cellulose to produce sorbitol and mannitol

[0032] 1g of microcrystalline cellulose (microcrystalline, available from Alfa Aesar) was placed in a 150ml reactor filled with sufficient water (50ml), 0.2g of Ru / C catalyst was added, and filled with H 2 , the pressure in the reactor was 20atm, heated to 240°C, and reacted for 1.5 hours.

[0033] According to the following method, the conversion rate of cellulose and the productive rate of sorbitol and mannitol are detected:

[0034] Reaction product is carried out mass spectrometry, and the result shows, mass spectrometry gives the molecular ion peak that mass-to-charge ratio is 183, provides the molecular ion peak of mass-to-charge ratio 183 molecular weight on mass spectrum with the standard sample of sorbitol and mannitol coincides; The reaction product is carried out High-performance liquid phase analysis and quantification, (Agilent 1100Series HPLC, purchased by Beijing Agilent Co., Ltd., se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com