Photoelectric diode structure and method for making the same

A photodiode and grid technology, applied in circuits, electrical components, radiation control devices, etc., can solve the problems of photodiode photosensitive effect decline, poor photosensitive sensitivity, shallow penetration depth, etc., to achieve difficult photosensitive effect, signal The effect of improved noise ratio and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

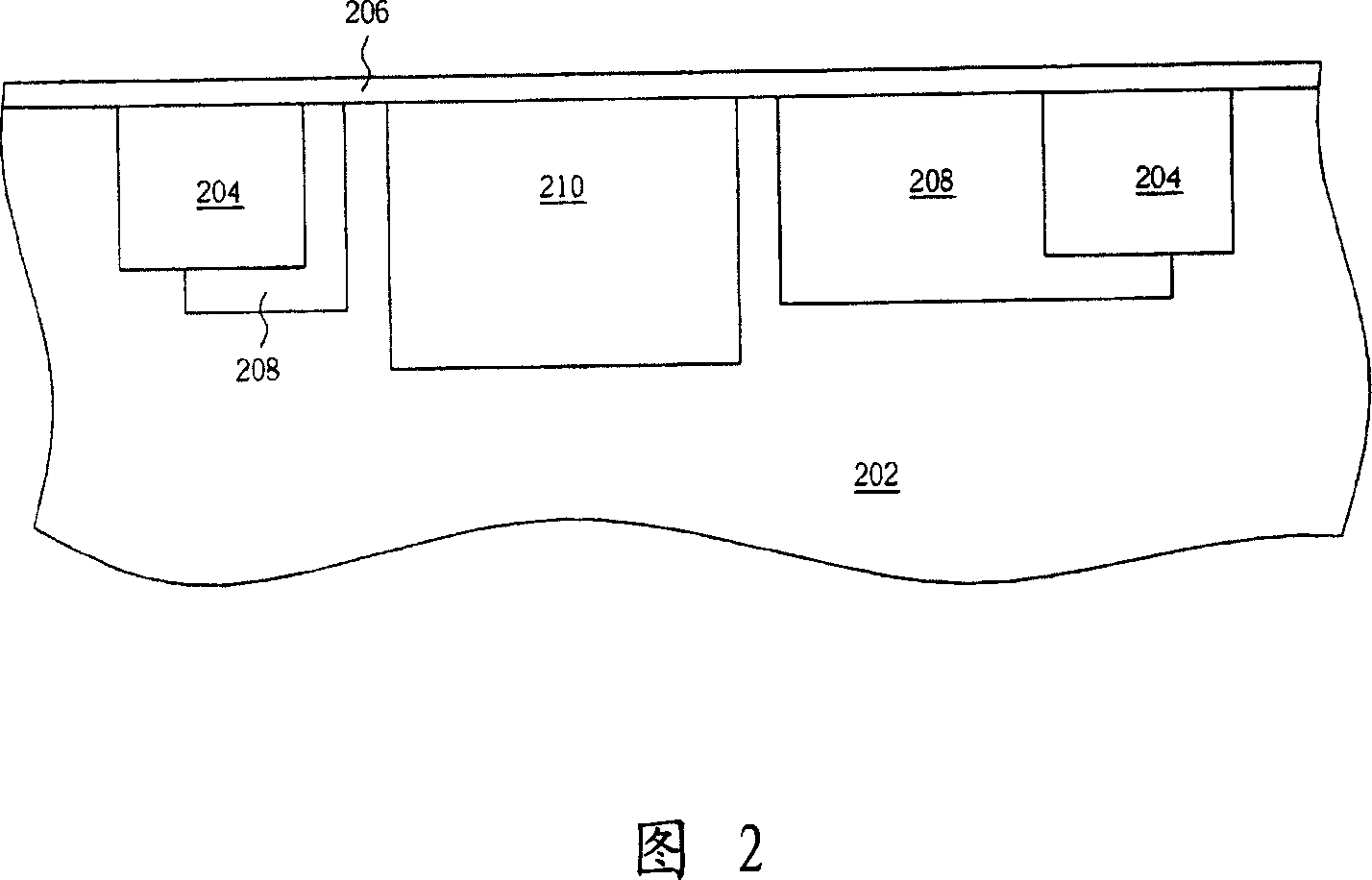

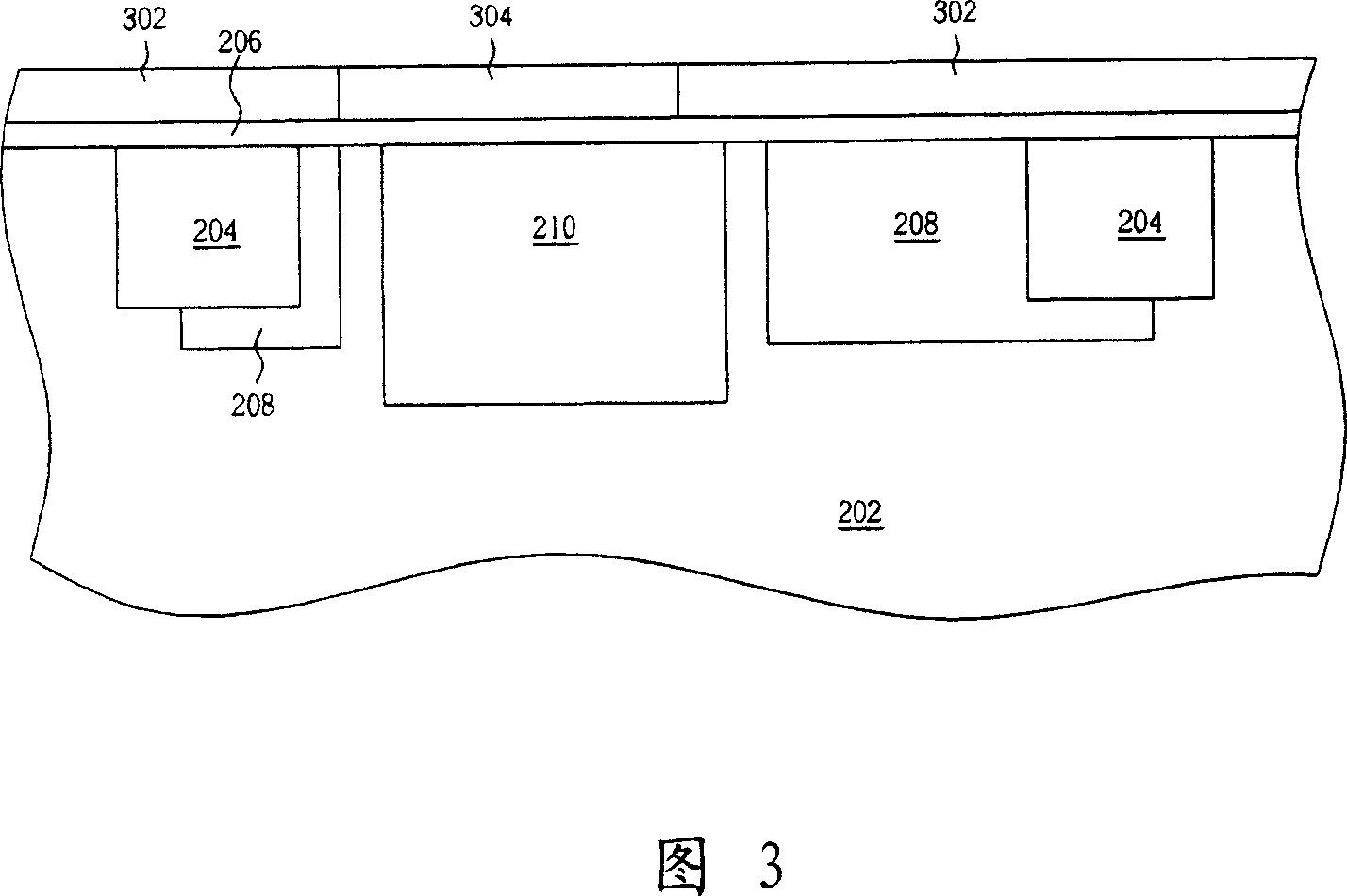

[0038] Please refer to FIG. 2 to FIG. 5 . FIG. 2 to FIG. 5 are schematic diagrams of a method for fabricating a photodiode according to a preferred embodiment of the present invention. As shown in FIG. 2, a P-type substrate 202 is first provided, and then, a plurality of shallow trench isolations 204 are formed in the P-type substrate 202, and then, a dielectric layer is formed on the surface of the P-type substrate 202 by oxidation or deposition process. , such as silicon dioxide (SiO 2 ) constitutes the oxide layer 206. Next, a patterned photoresist layer (not shown) is formed by photolithography, and an ion implantation process is performed to form a P-type guard ring (GR) 208 on the shallow trench isolation 204 The inner side, and the P-type guard ring 208 is deeper than the shallow trench isolation 204, which has the function of reducing the leakage current of the photodiode and improving the signal-to-noise ratio. Next, remove the patterned photoresist layer used to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com