Water heating reduction method preparing process for cuprous chloride

A cuprous chloride and preparation process technology, applied in the direction of cupric chloride, copper halide, etc., can solve the problems of difficult control, complicated process, polluted environment, etc., and achieve the effect of easy control and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

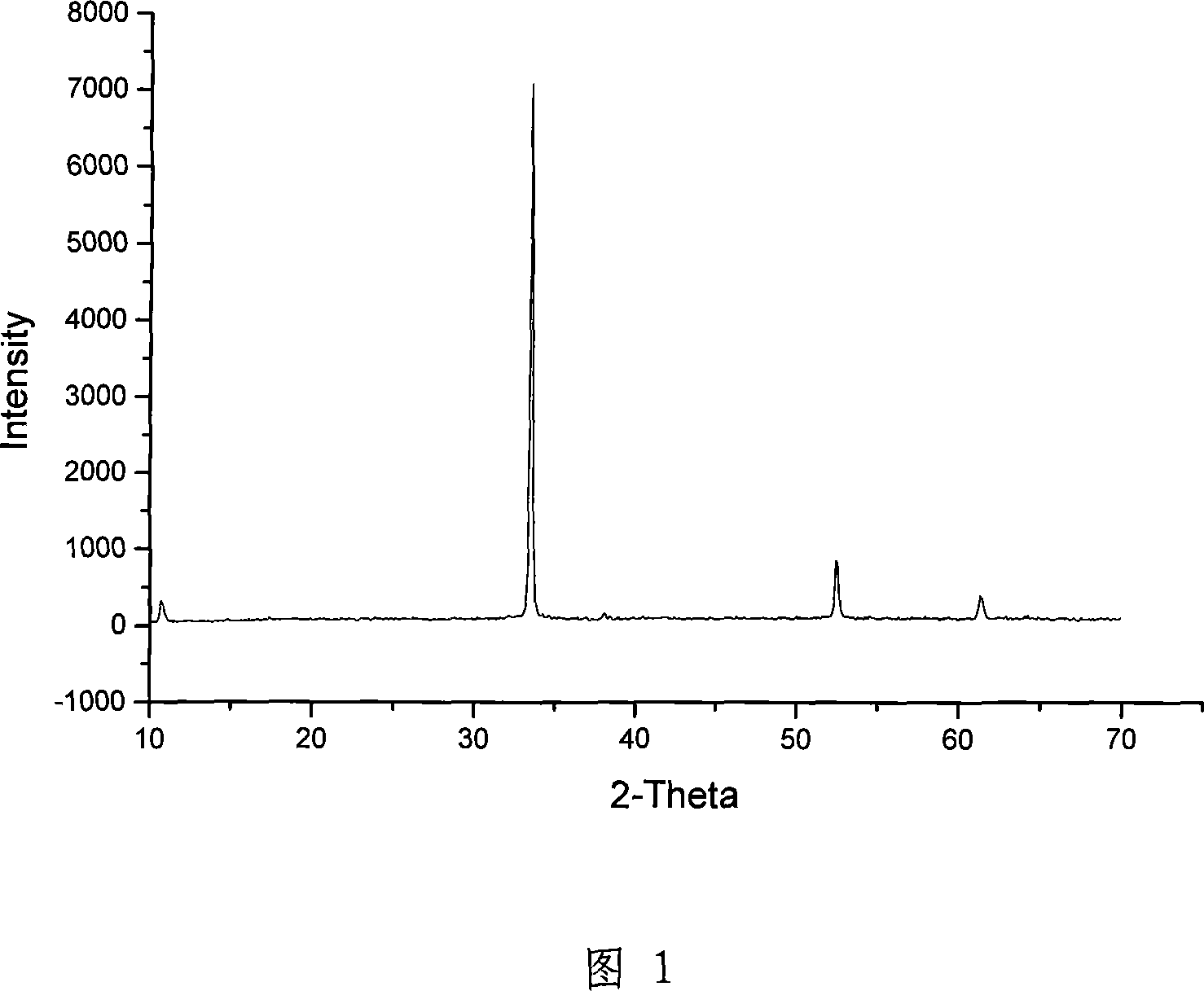

Embodiment 1

[0016] 250 grams of copper sulfate (CuSO 4 ·5H 2 (2, all the same in the following examples) and the mixed aqueous solution that 58.5 grams of sodium chloride are made into are as feed liquid, transfer in the pressure-resistant and corrosion-resistant reactor, then add reducing agent formaldehyde 30 grams (converted into 100% formaldehyde, implement below All the same in the example), airtight heating to 170 ℃, hydrothermal reduction reaction for 3 hours, generate cuprous chloride crystals, filter after cooling, wash and dry the cuprous chloride crystals filtered out according to conventional methods, and obtain the target product 80 grams of cuprous chloride crystals. The product is tested by XRD method and conforms to the standard spectrum of cuprous chloride crystal. The mother liquor after filtering out the cuprous chloride crystal is cooled after concentrating, sodium sulfate crystals are separated out, and the sodium sulfate crystal is removed by filtration, and the mo...

Embodiment 2

[0018] Transfer the mixed aqueous solution made of 250 grams of copper sulfate and 58.5 grams of sodium chloride into a pressure-resistant and corrosion-resistant reaction kettle, then add 45 grams of formaldehyde as a reducing agent, heat it to 160°C in a closed manner, and conduct a hydrothermal reduction reaction for 5 hours , generate cuprous chloride crystals, filter after cooling, wash and dry the cuprous chloride crystals that are filtered out according to conventional methods, and obtain 85 grams of target product cuprous chloride crystals. The product is tested by XRD method and conforms to the standard spectrum of cuprous chloride crystal.

Embodiment 3

[0020] A mixed aqueous solution made of 250 grams of copper sulfate and 58.5 grams of sodium chloride was used as a feed liquid, and transferred into a pressure-resistant and corrosion-resistant reaction kettle, and then 45 grams of formaldehyde was added as a reducing agent, sealed and heated to 150 ° C, and the hydrothermal reduction reaction was 8 Hour, generate cuprous chloride crystal, filter after cooling, the cuprous chloride crystal that will filter out is washed, dry process according to conventional method, obtain target product cuprous chloride crystal 82 grams. The product is tested by XRD method and conforms to the standard spectrum of cuprous chloride crystal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com