Super-high heat-conductive diamond-copper composite package material and production method

A technology for packaging materials and production methods, applied in metal material coating technology, chemical instruments and methods, and other chemical processes, etc., can solve the problems of weak interface bonding, small diamond particle size, poor thermal conductivity, etc., and improve the interface bonding strength. , Low thermal expansion coefficient, the effect of reducing the interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

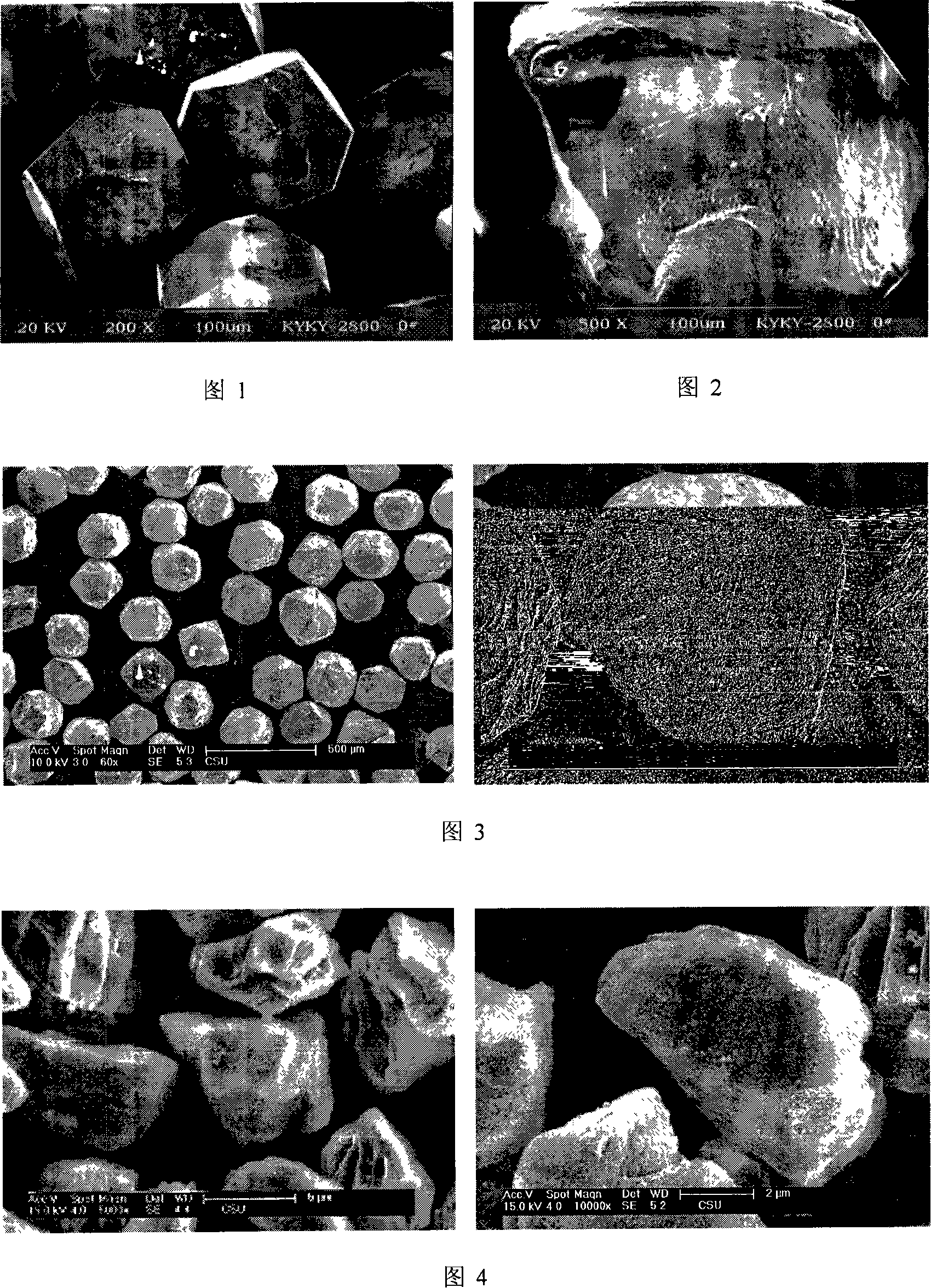

[0030] ①Select diamond particles with an average particle size of 10 μm for pretreatment, degreasing: place the diamond in 10% NaOH solution and boil it for 30 minutes with strong stirring, and then wash it with distilled water until neutral; roughening: then boil it in 30% dilute nitric acid solution for 30 minutes, Rinse with distilled water until neutral. Fig. 1 is a photo of the diamond particle morphology before processing, and Fig. 2 is a photo of the diamond particle morphology after roughening;

[0031] ② Electroless Cu plating on diamond surface, diamond electroless copper plating condition: CuSO 4 ·5H 2 O 15g·L -1 , 36% formaldehyde 15g L -1 , Potassium Sodium Tartrate 14g·L -1 , EDTA 14.6g·L -1 , NaOH to adjust the pH appropriately, bipyridine 0.02g·L -1 , Potassium ferrocyanide 0.01g L -1 , pH value 12.5, temperature 43°C, plating time 20 minutes, coating thickness 1 μm, the SEM photo of diamond particles after electroless Cu plating is shown in Figure 3;

...

Embodiment 2

[0035]①Select diamond particles with an average particle size of 50 μm for pretreatment, degreasing: place the diamond in 10% NaOH solution and boil for 30 minutes with strong stirring, then rinse with distilled water until neutral; roughening: then boil in 30% dilute nitric acid solution for 30 minutes, Rinse with distilled water until neutral;

[0036] ② Electroless Ag plating on diamond surface, diamond electroless silver plating condition: AgNO 3 1.5g·L -1 , Ammonia 10g·L -1 , Formaldehyde 0.15mL·L -1 , ethanol 100mL·L -1 , temperature 35°C, time 60min, coating thickness 3μm. The SEM photo of diamond particles after Ag plating is shown in Figure 4;

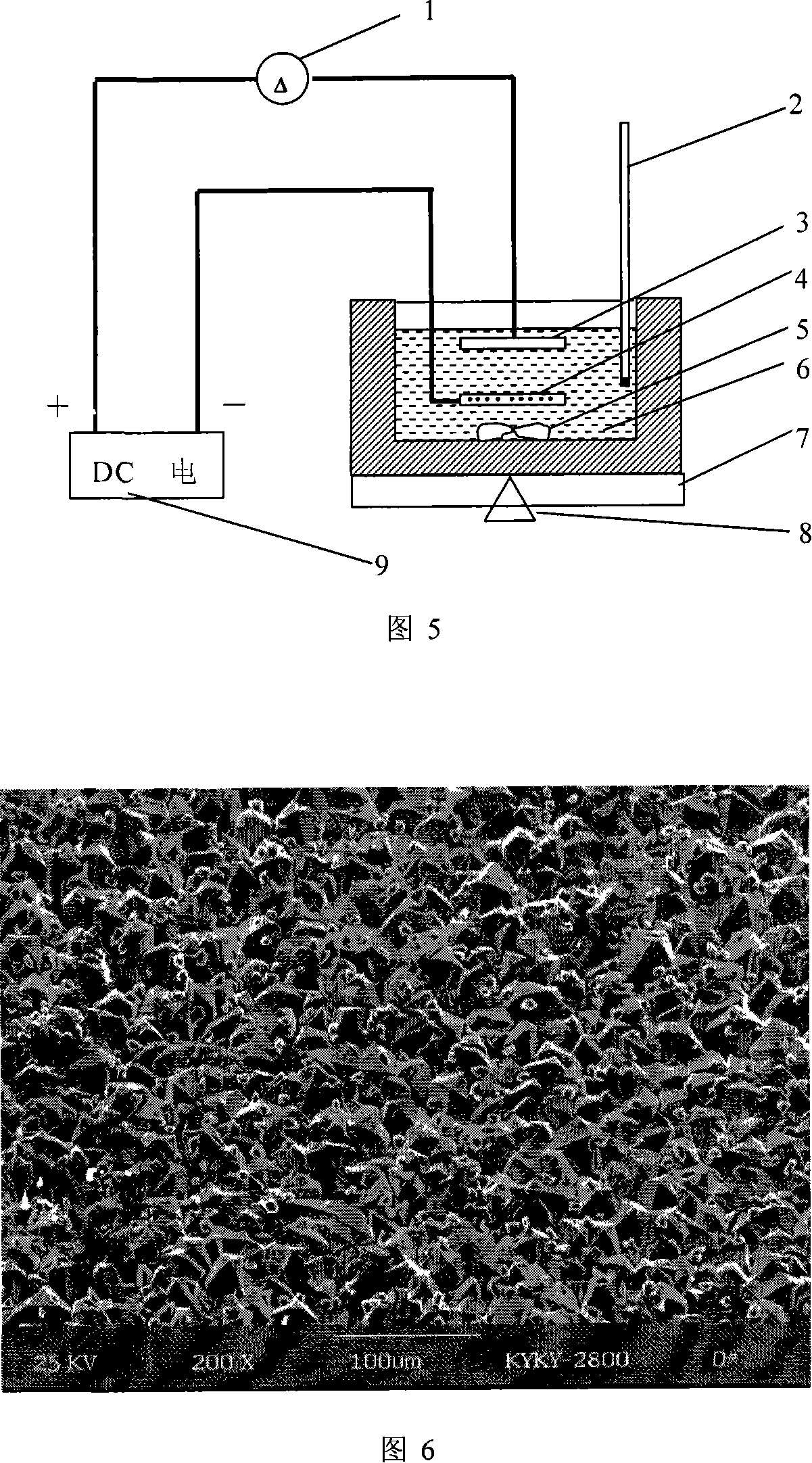

[0037] ③ Evenly disperse the diamond particles after electroless Ag plating in a copper mold, use the mold as the cathode, the copper sulfate solution as the electrolyte, and the pure copper plate as the anode, and conduct electrodeposition. The composition of the electrodeposition solution: copper sulfate (CuSO 4 ·5H ...

Embodiment 3

[0040] ①Select diamond particles with an average particle size of 150 μm for pretreatment, degreasing: put the diamond in 10% NaOH solution and boil it for 30 minutes with strong stirring, and then rinse it with distilled water until neutral; roughening: then boil it in 30% dilute nitric acid solution for 30 minutes, Rinse with distilled water until neutral;

[0041] ② Electroless Ag plating on diamond surface, diamond electroless silver plating condition: AgNO 3 1.5g·L -1 , Ammonia 10g·L -1 , Formaldehyde 0.15mL·L -1 , ethanol 100mL·L -1 , The temperature is 35°C, the plating time is 60 minutes, and the coating thickness is about 6 μm;

[0042] ③ Evenly disperse the diamond particles after electroless Ag plating in a copper mold, use the mold as the cathode, the copper sulfate solution as the electrolyte, and the pure copper plate as the anode, and conduct electrodeposition. The composition of the electrodeposition solution: copper sulfate (CuSO 4 ·5H 2 O) 180g·L -1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com