Method of producing high visible light active nano titanium dioxide photocatalyst codoped with nitrogen and indium

A nano-photocatalyst, titanium dioxide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of difficult to achieve industrial scale production, high equipment requirements, high cost, etc., to achieve visible light activity improvement , low equipment requirements, and small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

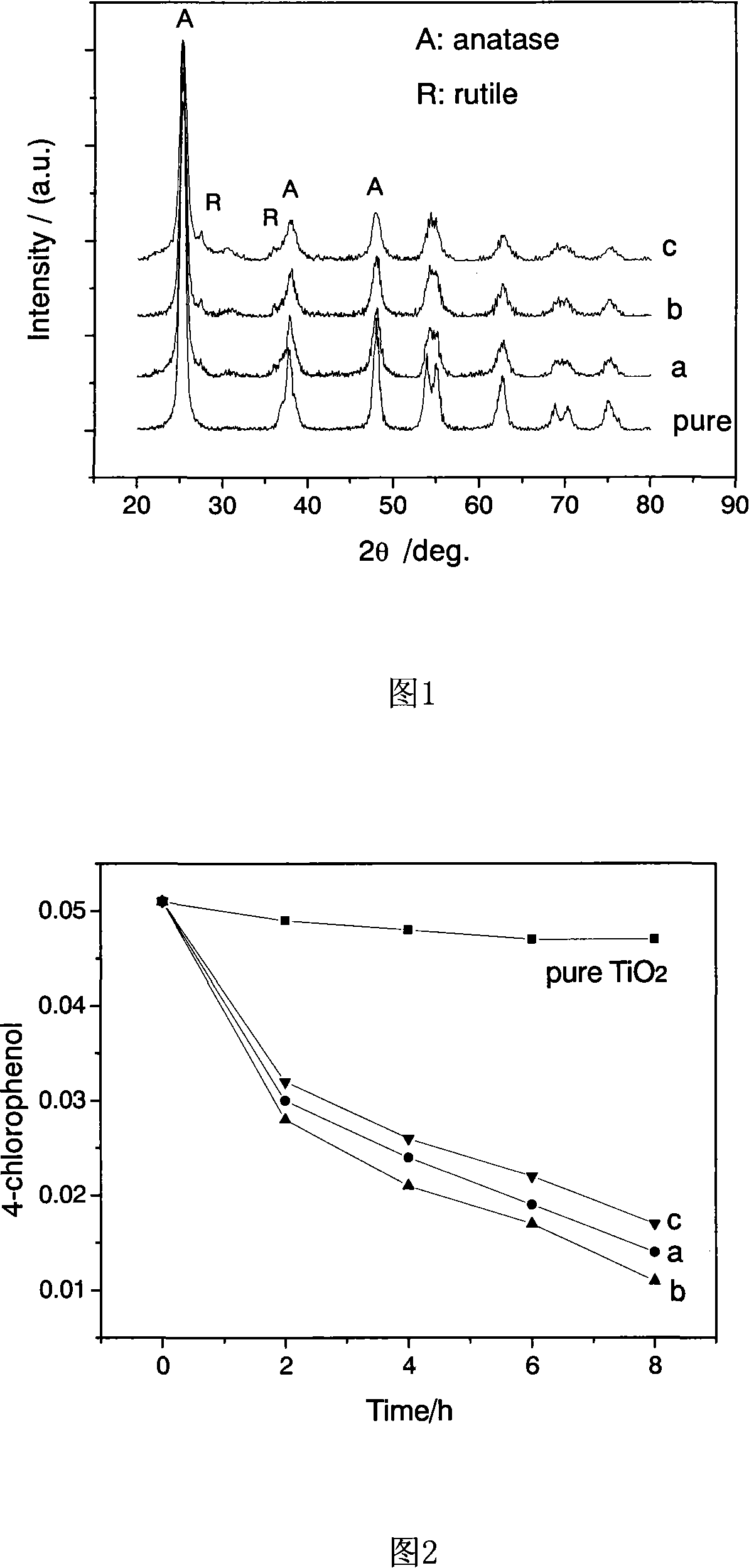

Embodiment 1

[0018] Take 3.03ml of InCl with a concentration of 0.6mol / L at room temperature 3 Put the solution into a beaker, add 40ml of absolute ethanol, and stir on a magnetic stirrer to obtain a mixed solution. Slowly add 12ml of tetrabutyl titanate (concentration: 98%) to obtain a uniform light yellow transparent solution. The pH value is controlled at about PH=0.5 by adding a certain amount of HCl. After 5 minutes, 3 ml of 25% ammonia water was added, and a precipitate formed rapidly. Put the white precipitate in a watch glass, put it in an oven, and bake it at 100°C for 12 hours to obtain dry amorphous doped TiO 2 Powder. Grinding, and finally putting the dry powder into a muffle furnace, calcining at 450°C for 2.5 hours to obtain nitrogen and indium double-doped TiO 2 Nano powder catalyst (a). In this catalyst, TiO 2 Be anatase phase and rutile phase mixed crystal (see the XRD spectrogram a curve of accompanying drawing 1 sample), wherein TiO 2 The molar ratios to the In ele...

Embodiment 2

[0020] Experimental condition, step are the same as embodiment one, change InCl 3 The addition amount of solution is 4.33ml, makes TiO 2 Nitrogen-indium double-doped TiO with molar ratios of In and N elements of 100:7.53 and 0.86:1, respectively 2 For the rice powder catalyst (b), using the above photocatalytic activity evaluation method, the degradation rate of p-chlorophenol was 78.43% after 8 hours under visible light irradiation.

Embodiment 3

[0022] Experimental condition, step are the same as embodiment one, change InCl 3 The addition amount of solution is 6.40ml, makes TiO 2 Nitrogen and indium double-doped TiO with molar ratios of In and N elements of 100:11.11 and 0.86:1, respectively 2 Nano powder catalyst (c), using the above photocatalytic activity evaluation method, under visible light irradiation, the degradation rate of p-chlorophenol after 8 hours is 66.67%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com