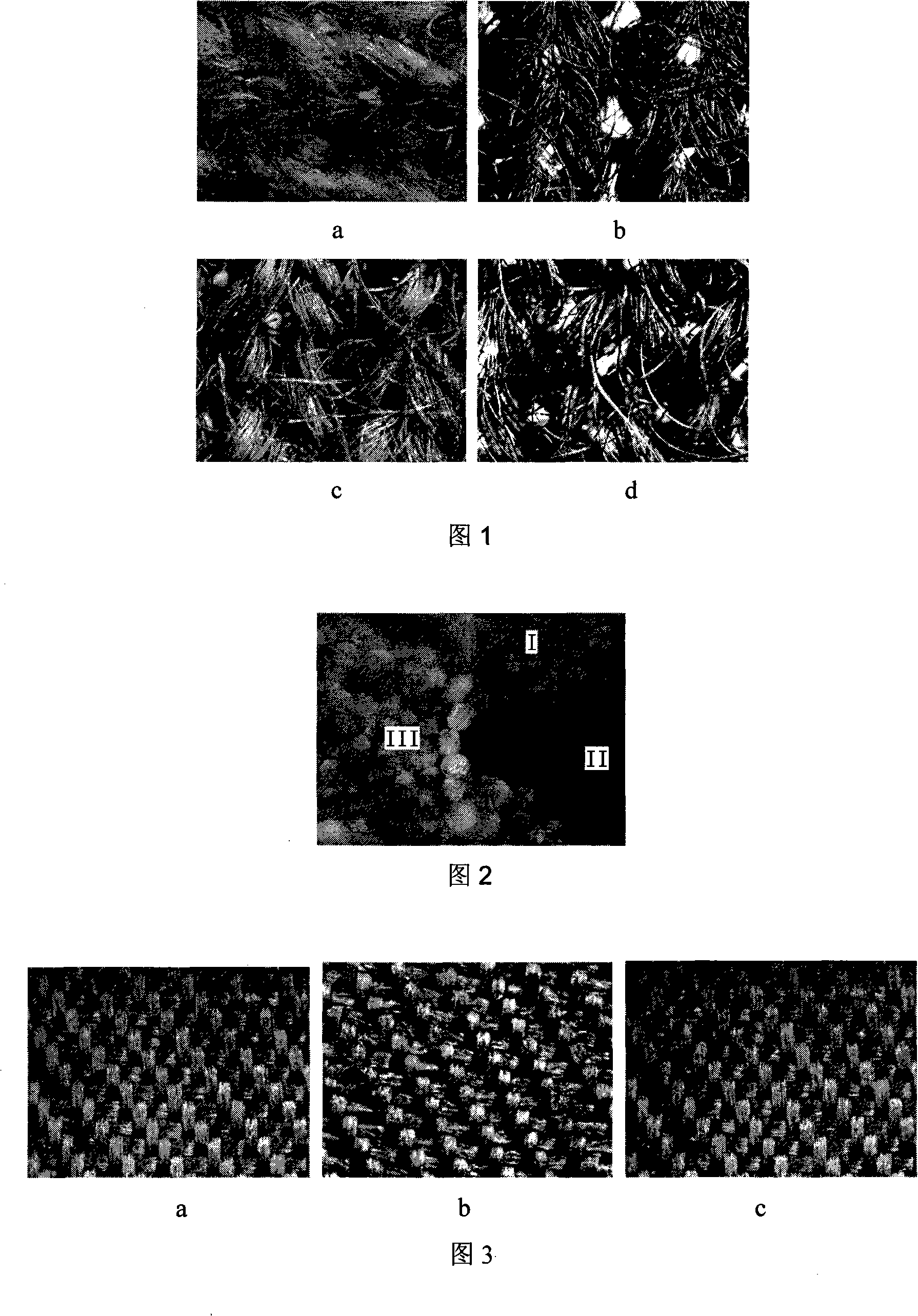

Method for identifying distribution of aminosiloxane sol in textile fibers

An aminosiloxane sol and aminosiloxane technology, applied in textile testing, color/spectral characteristic measurement, material inspection products, etc., can solve problems such as inconvenient distribution of sol particles, poor feasibility, and large spot size , to achieve the effect of simple and practical method, accurate and obvious results, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Fabric dyeing

[0029] Dyeing prescription:

[0030] C.I. Acid Green 16 dye 30% o.w.f

[0031] Acetic acid adjust pH=5

[0032] Bath ratio 100:1

[0033] Dyeing equipment: Taiwan RAPID H-12F dyeing machine

[0034] Dyeing process: Keep dyeing at 40°C for 3min, heat up to 80°C at a rate of 2°C / minute, then heat up to 98°C at a rate of 1°C / minute, and keep it warm for 60 minutes. After dyeing at 95℃, soaping for 20min to remove floating color, then wash the fabric with water and dry at 120℃.

[0035] (2) Sol preparation and finishing

[0036] In a water bath, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (AEAPTMS) and water were mixed and stirred at a molar ratio of 1:20 for 30 minutes to prepare an amino sol.

[0037] In a water bath, γ-glycidoxypropyltrimethoxysilane (GPTMS) and water (pH 3.5) were mixed and stirred at a molar ratio of 1:35 for 30 minutes to prepare a non-amino sol.

[0038] Two pieces of dyed and dried wool fabrics were soaked in the sol for 10 minute...

Embodiment 2

[0047] (1) Fabric dyeing

[0048] Dyeing prescription:

[0049] C.I. Acid Green 16 dye 3%o.w.f

[0050] Acetic acid adjust pH=5

[0051] Bath ratio 100:1

[0052] Dyeing equipment: Taiwan RAPID H-12F dyeing machine

[0053] Dyeing process: Keep dyeing at 40°C for 3min, heat up to 80°C at a rate of 2°C / minute, then heat to 95°C at a rate of 1°C / minute, and keep it for 30 minutes. After dyeing, soaping at 95°C for 10 minutes to remove floating colors, then the fabric is washed with water and dried in an oven at 100°C.

[0054] (2) Sol preparation and finishing

[0055] In a water bath, N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane (AEAPTMS) and water were mixed and stirred at a mass ratio of 1:20 for 30 minutes to prepare a sol.

[0056] In a water bath, γ-glycidoxypropyltrimethoxysilane (GPTMS) and water (pH 3.5) were mixed and stirred at a mass ratio of 1:35 for 30 minutes to prepare a non-amino sol.

[0057] The two dyed and dried wool fabrics were soaked in the above-mentioned s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com