Method for preparing fluorescing gold nano particles

A technology of gold nanoparticles and fluorescence, which is applied in the field of preparation of fluorescent gold nanoparticles, can solve the problems of low yield and harsh conditions, and achieve the effects of high yield, uniform distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 20ml of chloroauric acid aqueous solution (1mM), add 0.2ml of sodium citrate aqueous solution (112mM), add dropwise 1.5ml of 38.8mM sodium borohydride aqueous solution, stir and react at room temperature for 1 hour; then add 20ml

[0021] N,N'dibutyldithiocarboxylate octylfluorene (DBDTCC 8 F) in ethanol solution (1 mM), after 2 minutes, 20 ml of chloroform was added, stirred for 5 minutes, and separated. Separate the organic layer, wash with a large amount of ethanol, evaporate chloroform in vacuum, and dry in vacuum to obtain a black solid that is DBDTCC 8 F-modified gold nanoparticle composites.

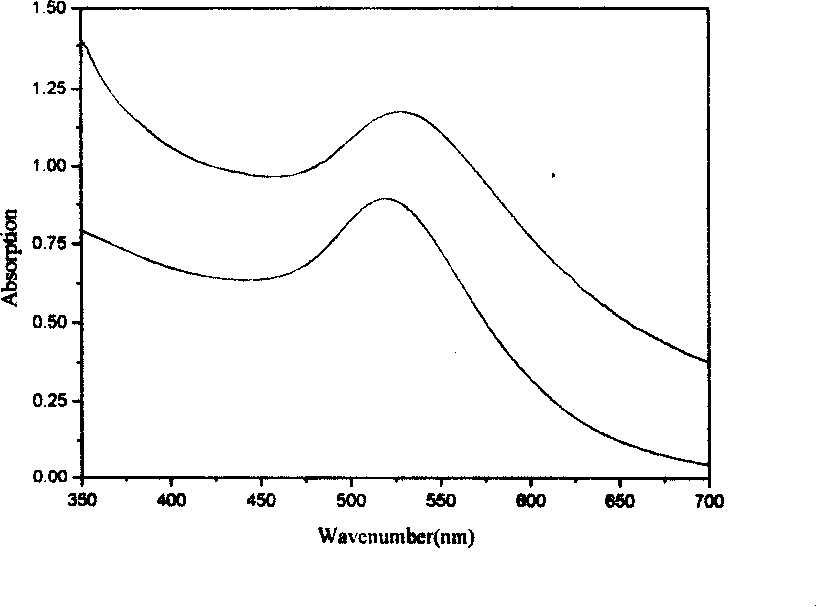

[0022] figure 1 A gold nanoparticle hydrosol (a) and N,N'dibutyldithiocarboxylate octylfluorene (DBDTCC 8 F) UV-Vis spectra of modified gold nanoparticles (b).

Embodiment 2

[0024] Take 20ml of chloroauric acid aqueous solution (1mM), add 0.3ml of sodium citrate aqueous solution (112mM), add dropwise 1.5ml of 38.8mM sodium borohydride aqueous solution, and stir at room temperature for 2 hours; then add 10ml of DBDTCC 8 F in ethanol solution (1 mM), after 3 minutes, add 20 ml of chloroform, stir for 10 minutes, and separate layers. Separate the organic layer, wash with a large amount of ethanol, evaporate chloroform in vacuum, and dry in vacuum to obtain a black solid that is DBDTCC 8 F-modified gold nanoparticle composites.

[0025] figure 2 N, N'dibutyldithiocarboxylate octylfluorene (DBDTCC 8 F) Transmission electron micrograph of modified gold nanoparticles. It can be seen that the prepared nanoparticles have a uniform particle size, with a diameter of 4-10 nm, and the length of the scale is 100 nm.

Embodiment 3

[0027] Take 20ml of chloroauric acid aqueous solution (1mM), add 0.4ml of sodium citrate aqueous solution (112mM), add dropwise 2.0ml of 38.8mM sodium borohydride aqueous solution, and stir at room temperature for 3 hours; then add 20ml of DBDTCC 8 F in ethanol solution (1 mM), after 4 minutes, 20 ml of chloroform was added, stirred for 15 minutes, and the layers were separated. Separate the organic layer, wash with a large amount of ethanol, evaporate chloroform in vacuum, and dry in vacuum to obtain a black solid that is DBDTCC 8 F-modified gold nanoparticle composites.

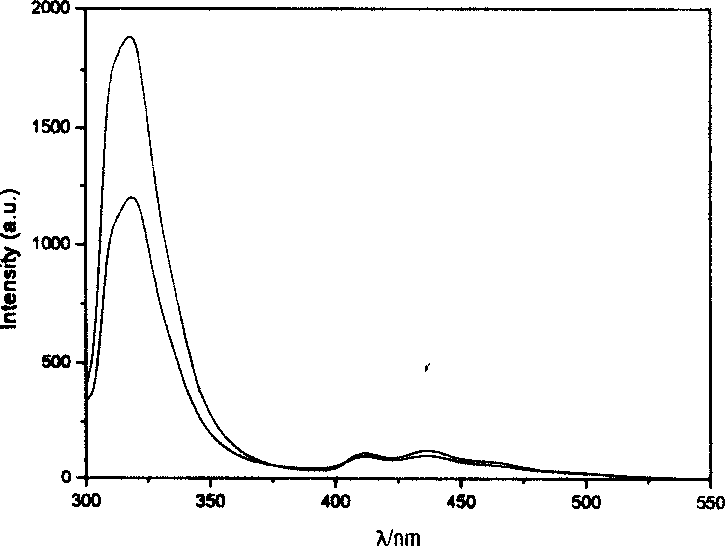

[0028] image 3 N, N'dibutyldithiocarboxylate octylfluorene (DBDTCC 8 F) Fluorescence spectra of (a) and its modified gold nanoparticles (b).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com