Method for preparing high dispersancy nano hydroxyapatite colloidal sols in water solution

A nano-hydroxyapatite, high-dispersion technology, applied in chemical instruments and methods, phosphorus compounds, colloid chemistry, etc., can solve the problem of inability to synthesize hydroxyapatite nanoparticle sol, particle crystallinity, and particle morphology. Good, surfactant or stabilizer toxicity and other issues, to achieve the effect of improving mechanical properties, low requirements for experimental conditions, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Add 100ml of 0.01M soluble calcium salt solution to 100ml of sodium citrate solution with a concentration of 0.00884g / ml, stir vigorously and heat up to 80°C;

[0020] (2) After 20min, add dropwise a soluble phosphate solution whose concentration is 2 / 3 of the calcium salt solution concentration and whose volume is equal to it at a speed of 50ml / h;

[0021] (3) Keep the constant temperature for 2 hours, and keep stirring. After the reaction is over, let it cool naturally. After the reaction system drops to room temperature, add anhydrous ethanol with the same volume as the reaction system to the reaction system and let it stand for 30 minutes. Centrifuge for 10 minutes (4000r / m), and wash the precipitate with deionized water;

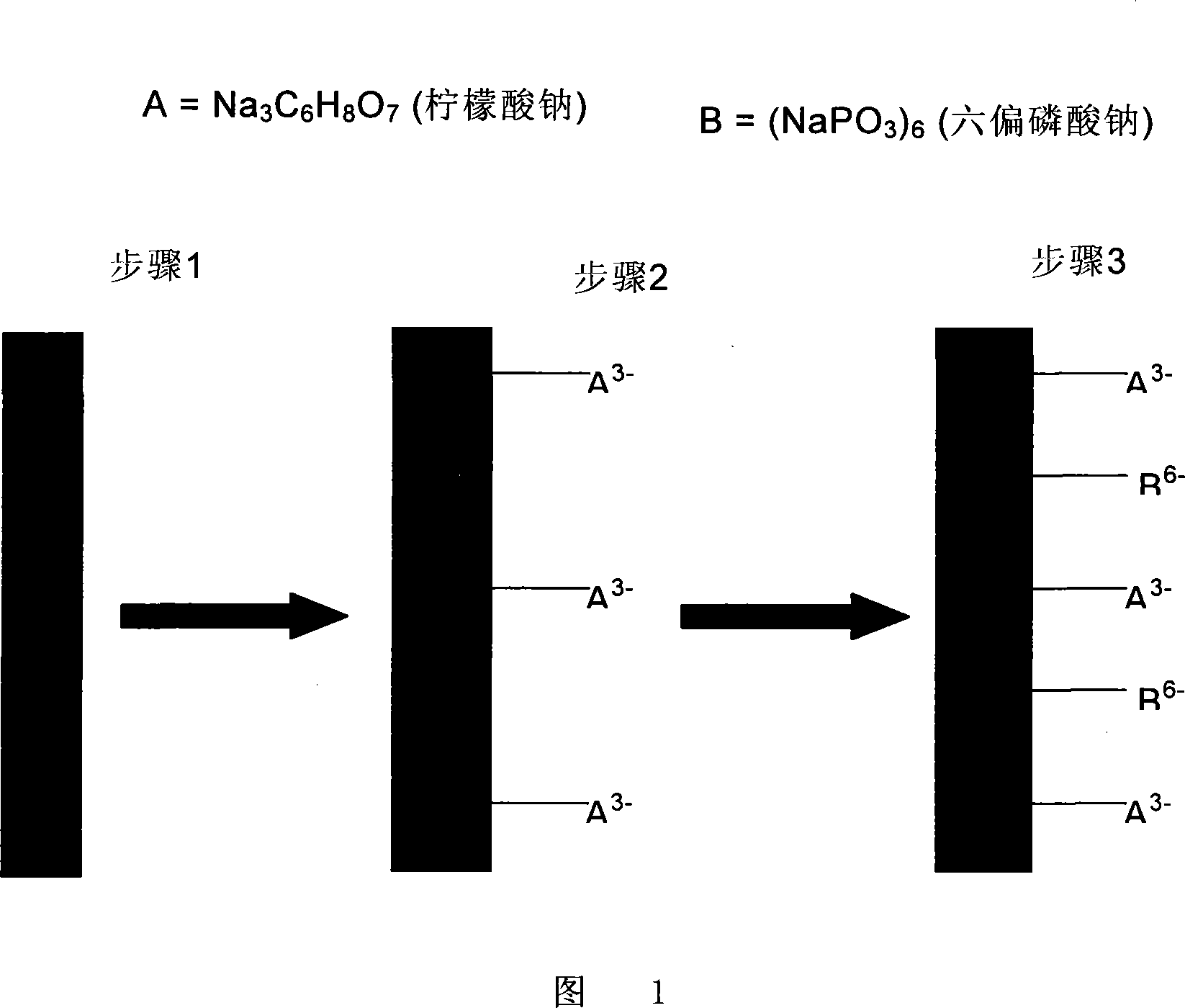

[0022] (4) Stir and disperse the freshly washed precipitate in deionized water while adding sodium hexametaphosphate solution with a concentration of 0.03g / ml until the color of the system changes from pure white to slightly white and translu...

Embodiment 2

[0025] (1) Add 200ml of 0.025M soluble calcium salt solution into 100ml of sodium citrate solution with a concentration of 0.009g / ml, stir vigorously and heat up to 90°C;

[0026] (2) After 20 minutes, add dropwise a soluble phosphate solution whose concentration is 2 / 3 of the calcium salt solution concentration and whose volume is equal to it at a speed not greater than 50ml / h;

[0027] (3) Keep the constant temperature for 2 hours, and keep stirring. After the reaction is over, let it cool naturally. After the reaction system drops to room temperature, add anhydrous ethanol with the same volume as the reaction system to the reaction system and let it stand for 30 minutes. Centrifuge for 10 minutes (4000r / m), and wash the precipitate with deionized water;

[0028] (4) Stir and disperse the freshly washed precipitate in deionized water while adding sodium hexametaphosphate solution with a concentration of 0.05g / ml until the color of the system changes from pure white to slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com