Method for purifying itaconic acid from itaconic acid fermentation liquor or itaconic acid product mother liquid

A technology of itaconic acid and fermentation liquid, applied in the separation/purification of carboxylic acid compounds, etc., can solve the problems of three wastes pollution, low quality, large loss, etc., achieve high resin utilization rate, low production cost, and small production site Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 The first special resin prepared in the present invention is a metal ion type chelating resin. It uses acidic macroporous resin or gel resin as a carrier to chelate metal ions; it uses the affinity difference between itaconic acid and residual sugar and other impurities on the macromolecular metal adsorbent to realize the separation between itaconic acid and residual sugar. of complete separation.

[0031] The macroporous resin can be selected from acidic polystyrene macroporous resin or polymethyl methacrylate macroporous resin. As the cross-linking agent, polyene-based cross-linking agents such as divinylbenzene, trivinylbenzene, and dipropylenebenzene can be selected.

[0032] The weight ratio (W / W) of the crosslinking agent used in the resin to the resin is 4% to 20%, and the best is 10% to 14%.

[0033] The resin prepared by the invention has higher physical stability than common commercial resins, the sphericity after grinding is more than 99%, and is ...

Embodiment 2

[0034] Example 2 The second special resin prepared by the present invention is an acid ion type chelating resin. It takes basic macroporous resin or gel resin as carrier, and chelates organic acid radical and / or inorganic acid radical ion on it.

[0035]Acid ion type chelating resin is a network cross-linked interpolymer containing styrene, and / or acrylate, and / or methacrylate, and / or acrylonitrile, and / or vinylpyridine, etc., which belongs to alkaline Types of anionic resins and the chelating resins they produce after they are used as carriers to coordinate with inorganic and / or organic acid ions. They include three processes:

[0036] 1. Bulk resin synthesis

[0037] In one or more than one monovinyl-containing monomers used in the preparation of the cross-linked interpolymer of the present invention. One is a styrene-based monomer; the other non-limiting examples of said vinyl monomer include acrylic acid, methacrylic acid, acrylonitrile, acrylates (including methyl acry...

Embodiment 3

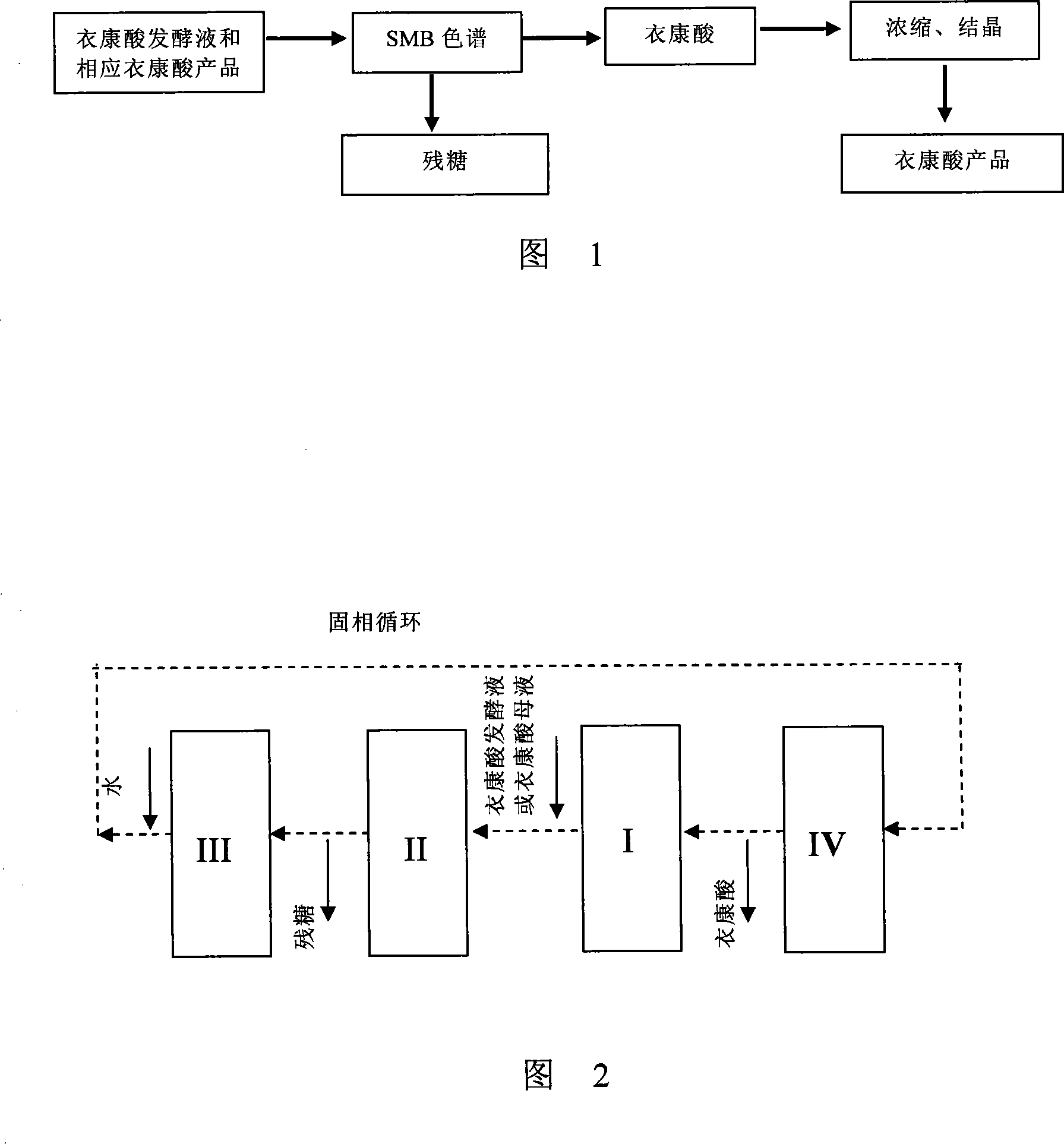

[0055] Simulated moving bed technology: The above-mentioned special resin is used as the stationary phase adsorbent in the simulated moving bed chromatographic separation device, and the difference in affinity between the functional group and impurities such as itaconic acid and residual sugar is used to realize the separation of itaconic acid and residual sugar. Complete separation between the materials; water is used as the eluent, the separation temperature is 35 ° C ~ 95 ° C, the optimum separation temperature is 70 ° C, continuous feeding and discharging operations are performed, and two types of output components are obtained at the same time, one is The component with itaconic acid purity of 95%-99.9% (generally >99%); the other is the component mainly containing sugar with itaconic acid purity <1%.

[0056] The simulated moving bed device of the present invention is composed of four or more chromatographic columns connected in series to form a closed system connected en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com