Tissue engineered fine particle tissue and method for preparing the same

A technology of microparticle tissue and tissue engineering, applied in medical science, prosthesis, etc., can solve the problem that the cells in the central part cannot get enough nutrients supply, there is no public information on tissue engineered microparticle tissue, and the metabolites are difficult to remove in time, etc. problem, to achieve good clinical treatment effect, good cell growth state, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

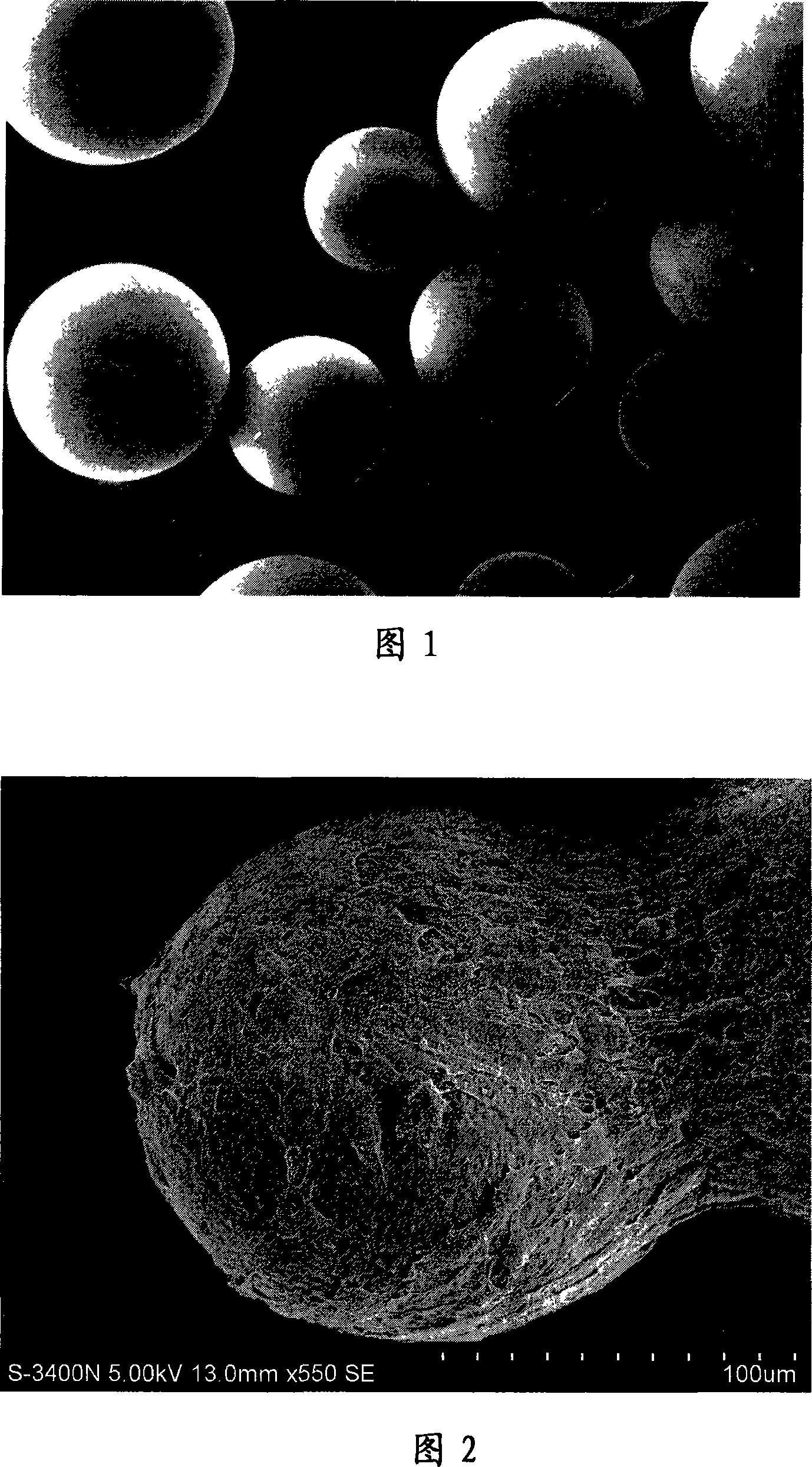

[0016] Example 1: Preparation of tissue engineered microparticle skin tissue

[0017] 1. Preparation of acellular dermal matrix (extracellular matrix) microcarriers: Take fresh back skin of pigs, cut into 5cm×10cm in size, take skin in reverse direction with a skin-taking drum, cut off the epidermis about 0.3mm thick skin slice, expose The dermis part; use the leather drum to cut out the dermis with a thickness of about 0.3mm, and set it aside.

[0018] Put the pig dermis in 2.5g / L trypsin solution to digest, after cleaning, put the pig dermis in -80℃ freezer for more than half an hour to ensure that the temperature inside and outside the dermis reaches the same; after taking it out, thaw naturally at room temperature, and freeze and thaw repeatedly for 2~ 5 times to make the cells completely rupture and disintegrate; after washing with water, soak the corium in 4% NaOH solution, replace the NaOH solution every 6 hours, and soak for 24 hours; then use PBS solution (phosphate b...

example 2

[0021] Example 2: Preparation of tissue engineered microparticle adipose tissue

[0022] 1. Preparation of gelatin microcarriers: refer to the literature [Wang Yijuan et al. Preparation of gelatin-based slow-release microspheres as cell microcarriers. Chemical Journal of Chinese Universities, 2007 28(9): 1776-1780] to prepare gelatin microcarriers, and to screen particles Microcarriers with a diameter of 250 μm to 350 μm were sterilized with cobalt 60 and stored for later use.

[0023] 2. Preparation of tissue-engineered adipose tissue microparticles: Under sterile conditions, soak 2 grams of gelatin microcarriers in 20 ml of cell culture medium (DMEM culture medium containing 10% fetal bovine serum) for 24 hours to make them fully swell, and remove them by centrifugation supernatant; then add 5ml of 1mg / ml polylysine solution to soak the microcarriers for 2 hours, discard the liquid; dry naturally under sterile conditions.

[0024] will contain 1×10 5 10ml of cell culture s...

example 3

[0025] Example 3: Preparation of tissue engineered microcartilage tissue

[0026] 1. Preparation of PLGA microcarriers: Reference [Jean-Manuel Péan et al. NGF release from poly(D, L-lactide-co-glycolide) microspheres.Effect of someformulation parameters on encapsulated NGF stability. Journal of Controlled Release. 1998 56(4 ): 175-187] Prepare PLGA microcarriers, screen the microcarriers with a particle size of 150 μm-250 μm, sterilize them with cobalt 60 and save them for later use.

[0027] 2. Preparation of tissue engineered microparticle cartilage tissue: under aseptic conditions, soak 20 ml of cell culture medium (FAD culture medium containing 10% fetal bovine serum, plus 5 ml of 2 mg / ml polylysine solution) 1 gram of PLGA microcarrier for 24 hours to make it fully swell; centrifuge to remove the supernatant, and then dry it naturally under aseptic conditions.

[0028] will contain 3 x 10 5 10ml of chondrocyte cell culture medium per ml was mixed with microcarriers, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com