Method and system for processing wastewater of cleaning printed circuit board

A printed circuit board and wastewater cleaning technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problems that operators are not easy to master, the wastewater treatment process is complicated, and the wastewater treatment equipment is huge. Achieve the effect of saving water expenses, alleviating the shortage of water resources, and remarkable effect of adsorption and filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

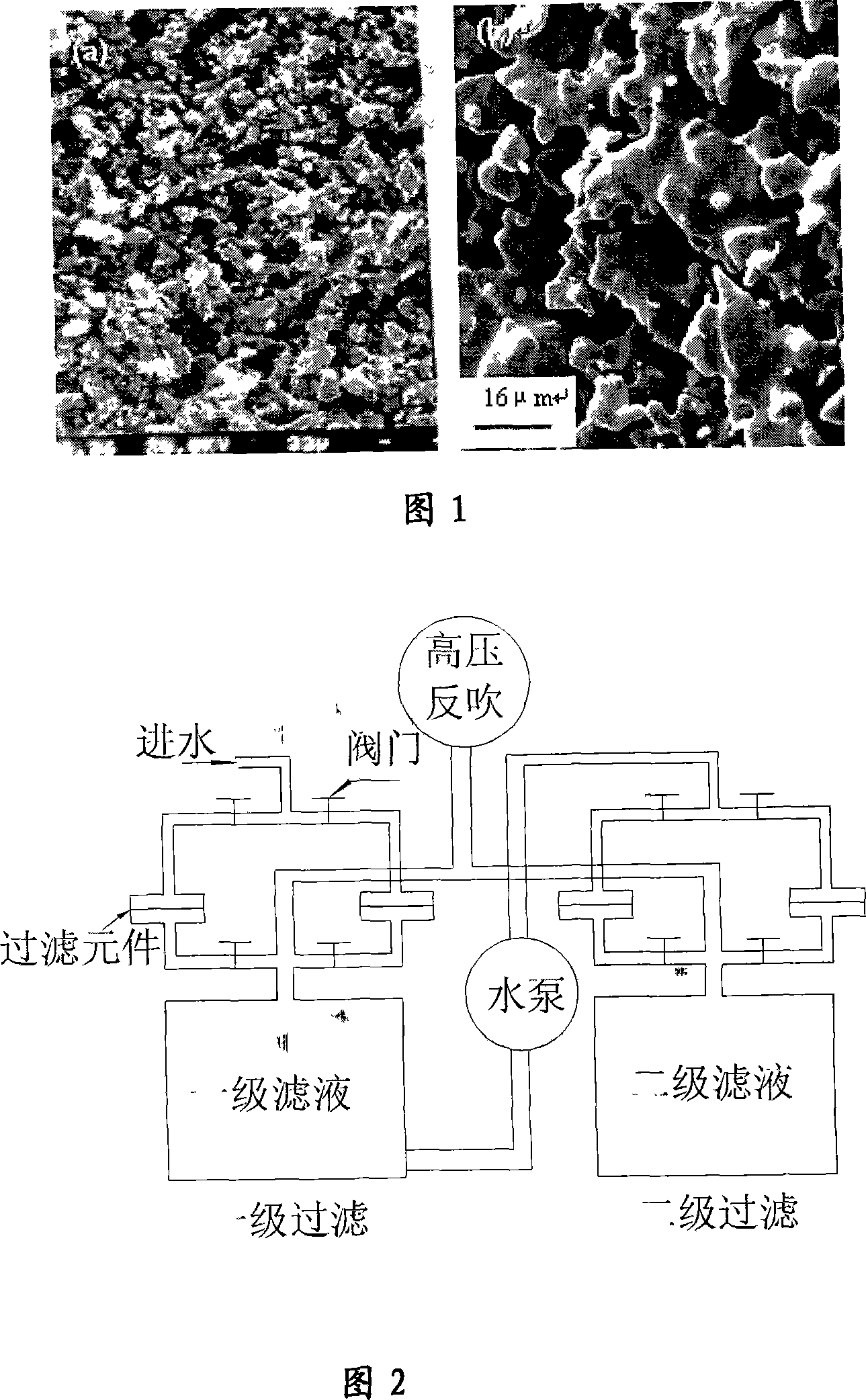

[0024] Embodiment 1 Preparation of SiC porous ceramic filter disc

[0025] Using 100 μm silicon carbide micropowder, carbon powder, clay and potassium feldspar, wet mixing according to the mass ratio of 45:35:12:8, dry pressing, and sintering at 1240°C to obtain the SiC porous ceramic filter , The porosity is 65%, the average pore diameter is 30μm, and the pores are distributed in a three-dimensional network.

Embodiment 2

[0027] Using 10 μm silicon carbide micropowder, carbon powder, clay and potassium feldspar, wet mixing according to the mass ratio of 40:50:6:6, dry pressing, sintering at 1280 ° C to obtain the SiC porous ceramic filter , The porosity is 60%, the average pore diameter is 5μm, and the pores are distributed in a three-dimensional network.

Embodiment 3

[0029]The cleaning wastewater of the printed circuit board factory contains the contents of Ni, Cu, and Pb elements: 155ng / mL, 11410ng / mL, and 1077ng / mL, respectively, and the pH is 10. The printed circuit board cleaning wastewater treatment device used in this embodiment is: a sedimentation tank, and the wastewater treatment process after the sedimentation tank is connected with 200 mesh and 400 mesh filter screens with apertures of 74 μm and 37 μm respectively, and then connected with a three-dimensional mesh with pores. The SiC porous ceramic filter sheet of shape distribution is the first-level depth filter device and the second-level depth filter device of filter element; sheet), the secondary depth filter is 5 μm (using the SiC porous ceramic filter prepared in Example 2), the SiC porous ceramic filter is supported by a carrier, sealed with a silica gel plate gasket, and connected by a flange; There are two branches in the device, and each branch is provided with a filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com