Method for producing alta-mud load TiO2 catalyst with metal organic chemical vapor deposition

A metal organic chemistry and vapor deposition technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, to achieve the effect of good adsorption performance, less variety of materials, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation principle of the present invention is:

[0023] MOCVD (metal-organic chemical vapor deposition) reaction mechanism is a growth mechanism under non-equilibrium state. Its principle is the process of using gas phase reactants or precursors to react on the surface of the substrate to form solid deposits on the surface of the substrate. . The reactive deposition process can be expressed as follows:

[0024] (CH 3 CH 3 CHO) 4 Ti(g)+K→L(g)

[0025] L(g)+X→L(a)

[0026] L(a)→M(g)+TiO 2 (s)

[0027] In the above formula (CH 3 CH 3 CHO) 4 Ti is the organic precursor tetraisopropyl titanate, K is the carrier gas, X is the growth point on the surface of the carrier, L(g) and L(a) are activated intermediates, and M is the decomposition byproduct.

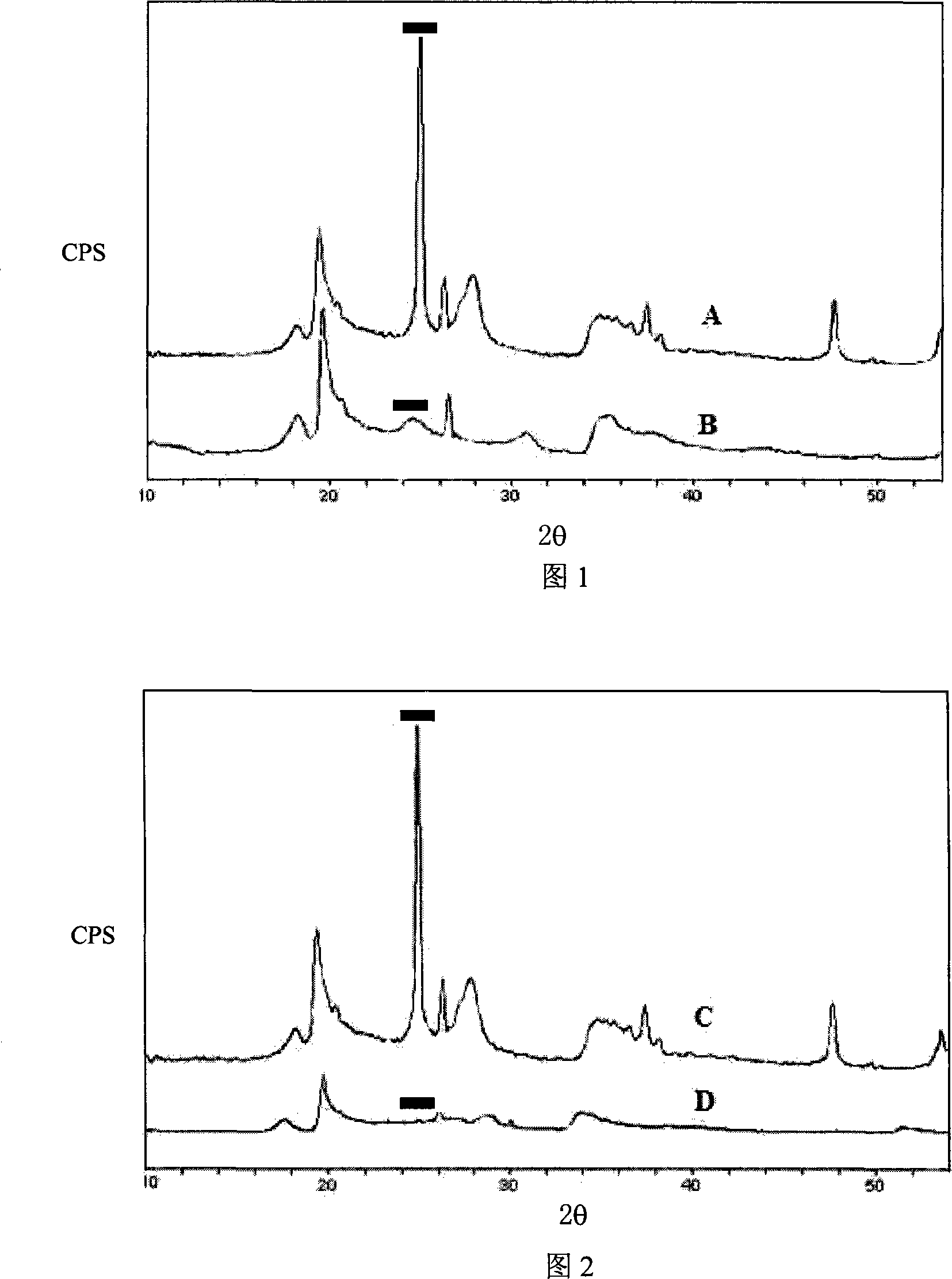

[0028] The main component of bentonite is montmorillonite. Montmorillonite is a 2:1 layered silicate mineral and belongs to the monoclinic crystal system. The unit cell is composed of two layers of silicon-oxygen tetrahedrons...

Embodiment 1

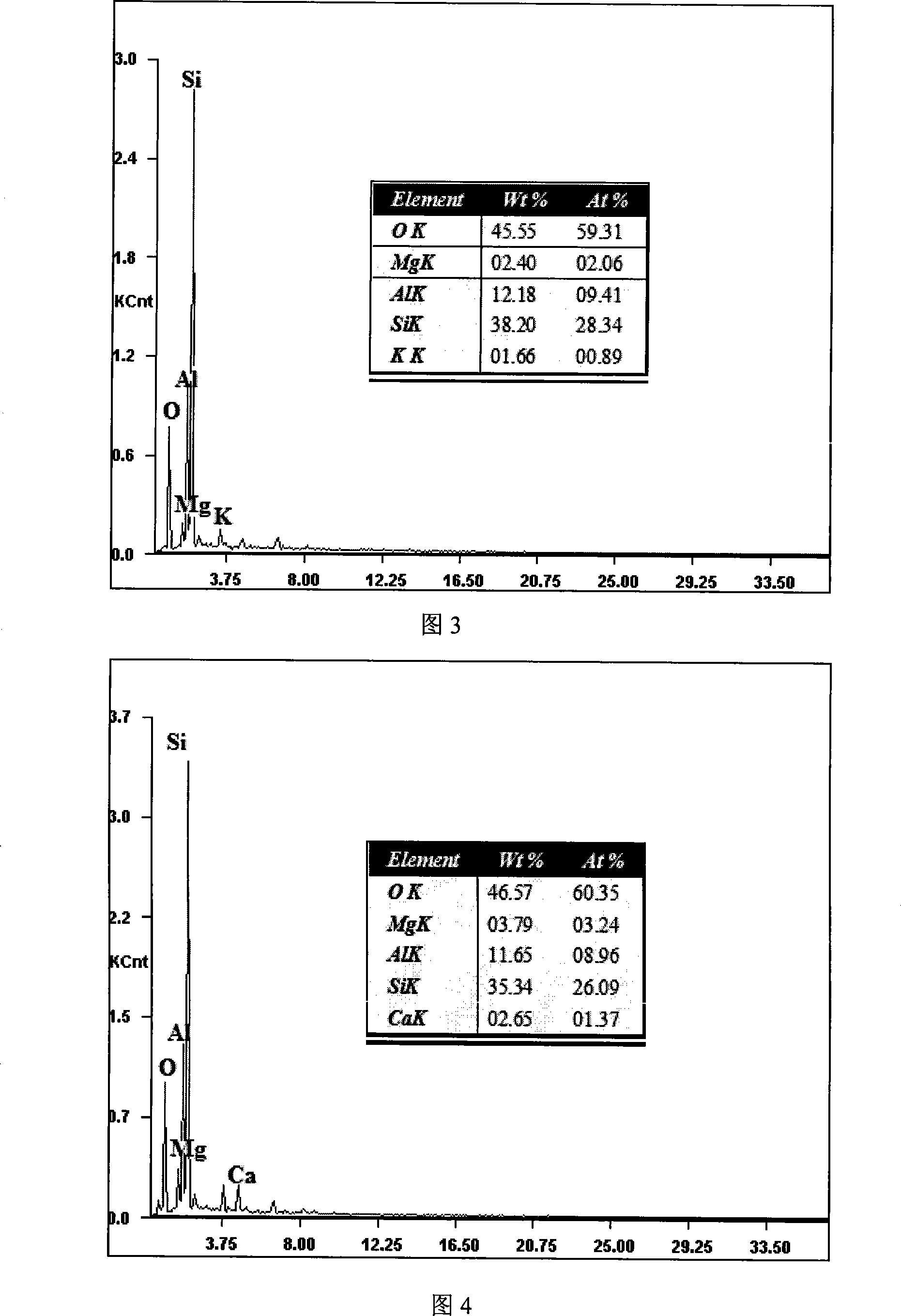

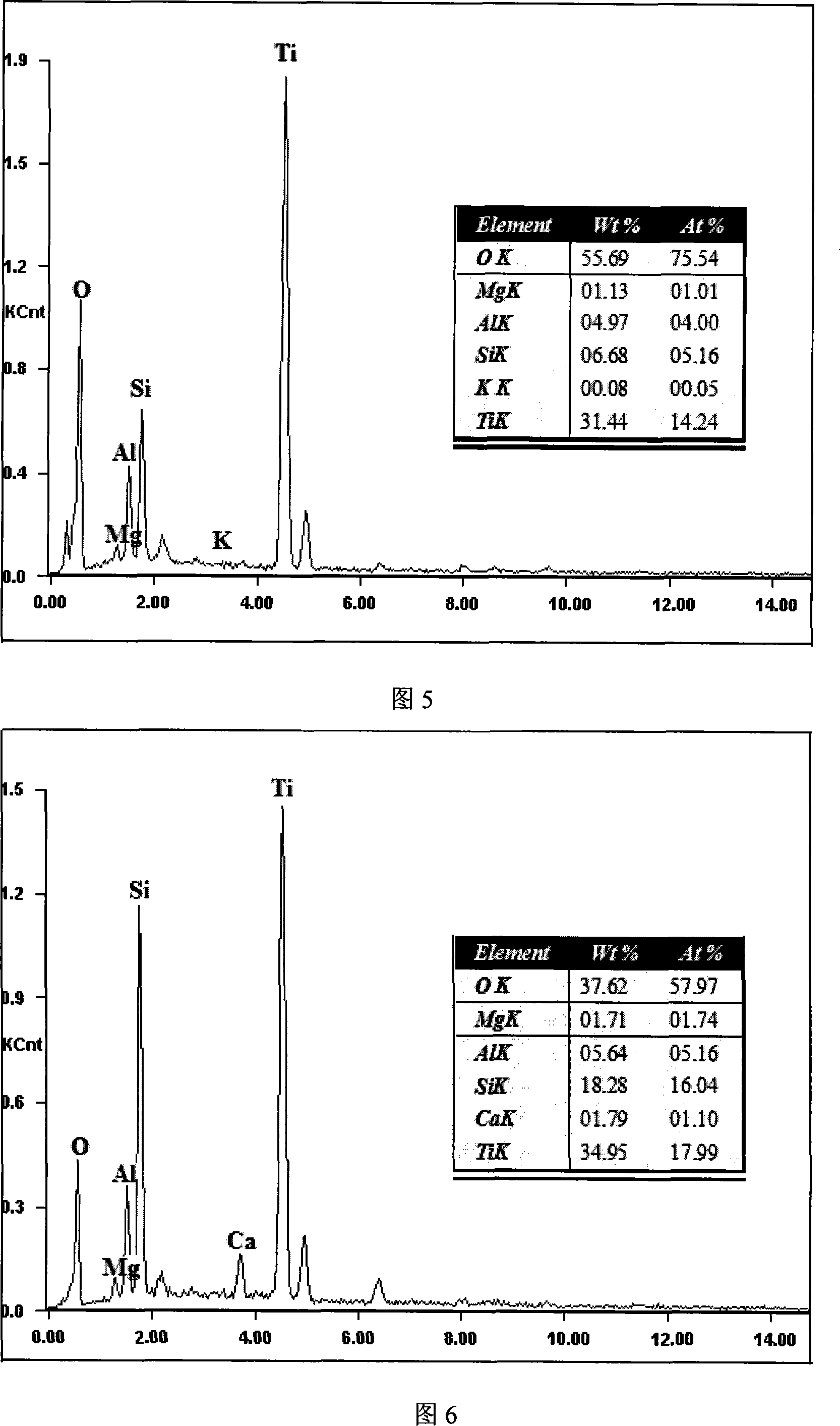

[0030] The bentonite loaded nanometer titanium dioxide catalyst of the present invention is a kind of composite material obtained by depositing nanometer titanium dioxide particles on the surface of the bentonite, and has the function of integrating adsorption and photocatalysis to degrade organic matter in waste water and exhaust gas.

[0031] The preparation method of bentonite-supported nano titanium dioxide in this embodiment is as follows:

[0032] 1) Put 5g aluminum pillared bentonite (Al-PILCS) with 100 meshes into the quartz reactor, open the drying gas path, and dry with nitrogen for 30 minutes, and the nitrogen flow rate is 0.1m3 / h;

[0033] 2) Close the drying gas path, open the reaction gas path, adjust the nitrogen flow rate to 0.4m3 / h, heat the quartz reactor to 550°C, the temperature rise time is 30 minutes, and heat the tetraisopropyl titanate to 60°C in a water bath to make the titanium The tetraisopropyl acid volatilizes into the quartz reactor and reacts for 3 h...

Embodiment 2

[0037] The difference from Example 1 is that the original bentonite clay is used as the supporting material for the test, and the bentonite of the present invention is prepared with TiO 2 powder. Proceed as follows:

[0038] 1) Put 5g of bentonite with 100 meshes into a quartz reactor, open the drying gas path, and dry with nitrogen for 30 minutes, with a nitrogen flow rate of 0.1m3 / h;

[0039] 2) Close the dry gas path, open the reaction gas path, and adjust the nitrogen flow rate to 0.4m 3 / h, the quartz reactor is heated to 550°C, the heating time is 30 minutes, and the tetraisopropyl titanate is heated to 60°C in a water bath to volatilize the tetraisopropyl titanate into the quartz reactor and react for 3 hours;

[0040]3) After the reaction, continue to pour nitrogen into the reactor to remove residual tetraisopropyl titanate, and calcinate under the protection of nitrogen for 1 hour. The calcining temperature is 550°C to make TiO 2 Complete growth and cooling to obtain alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com