Water-soluble cationic polymer adsorption material and applications thereof

A water-soluble cation and adsorption material technology, which is applied in the field of biomedical materials, can solve the problems of reduced ability to remove pathogenic factors, expensive treatment costs, and complicated equipment and devices, so as to improve blood compatibility and avoid non-specific adsorption. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

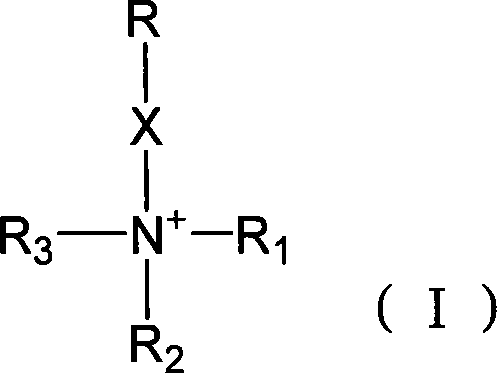

[0030] Embodiment 1. Synthesis of water-soluble cationic starch and its application in blood purification

[0031] The first step is to prepare the adsorbent material

[0032] Weigh 10 grams of starch with a viscosity average molecular weight ranging from 400 to 500KD and put it into a beaker, add 6ml of water to it, then add 5 grams of sodium hydroxide to the starch, and stir with an electric stirrer to make the sodium hydroxide and starch Mix well. Then add 28 grams of 2,3-epoxypropyltrimethylammonium chloride, add it to the mixture of starch and sodium hydroxide that has been stirred, make it evenly mixed, and then react at 70°C for 4 hours to obtain quaternary ammonium The crude starch product was washed with 80% ethanol, suction filtered and dried to obtain pure quaternized starch. The reaction formula is as follows:

[0033]

[0034] n=2469~3087 (corresponding to the starch molecular weight range of 400~500KD).

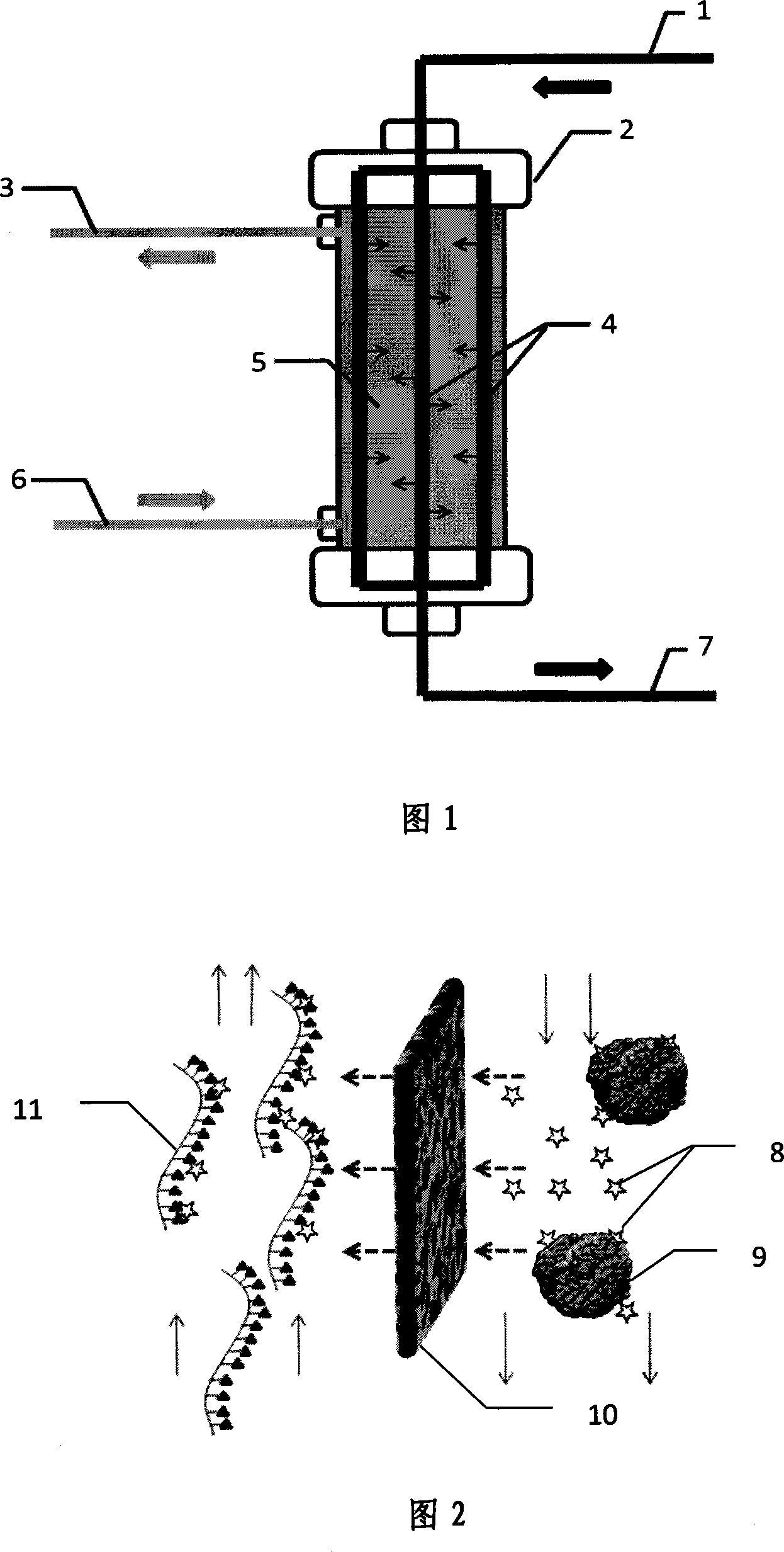

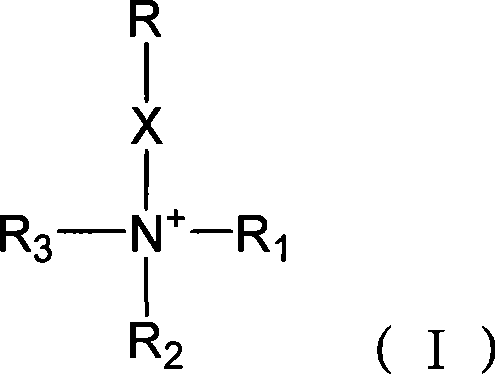

[0035] The second step, the preparation of dialysis...

Embodiment 2~6

[0039] The discarded plasma exchanged from patients with severe hepatitis was subjected to in vitro simulated adsorption dialysis experiments. The initial concentrations of bilirubin, bile acids, blood ammonia, creatinine, and urea in plasma were 248 mg / L, 203.5 μmol / L, and 97.55 μmol / L, respectively. , 287μmol / L, 13.65mmol / L. Nipro triacetate hollow fiber dialyzer SUREFLUX-130G was selected; 40ml of plasma from patients with severe hepatitis circulated in the hollow fiber membrane in the hemodialyzer at a flow rate of 100ml / min; the prepared adsorption dialysate with a concentration of 0.1% had a volume 200ml, through the outer cavity of the hemodialyzer, the flow rate is 100ml / min, and exchange solute with the blood in the hollow fiber membrane, the adsorption dialysis time is 4 hours. The experimental results show that the removal rates of various toxins are 23.8% for bilirubin, 49.6% for bile acid, 23.6% for blood ammonia, 45.6% for creatinine, and 17.7% for urea. Example...

Embodiment 7

[0043] Embodiment 7. chitosan and 2,3-epoxypropyltrimethylammonium chloride reaction synthesis adsorption material and its application

[0044] The first step is to prepare the adsorbent material

[0045] Weigh 10 grams of chitosan with a viscosity-average molecular weight range of 90 to 100KD, add 300ml of water, 30 grams of 2,3-epoxypropyltrimethylammonium chloride, and react at 75°C for 10 hours, and the reaction product Precipitate with ethanol or acetone, wash with 80% aqueous ethanol, filter with suction and dry to obtain a pure product. The reaction formula is as follows:

[0046]

[0047] n=559-622 (corresponding to chitosan molecular weight range of 90-100KD).

[0048] The second step, the preparation of dialysis adsorption solution

[0049] 1 gram of 2-hydroxypropyltrimethylammonium chloride chitosan was dissolved in 100 ml of bicarbonate dialysate, and the concentration of 1% (w / v) was configured as an adsorption dialysate.

[0050] The third step, hemoadsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com