Asphalt pavement conditioning curing agent and preparation method thereof

A technology of asphalt pavement and curing agent, which is applied in the preparation of asphalt pavement conditioning and curing agent, and in the field of asphalt pavement maintenance and repair. It can solve the problems of not too obvious effect, high cost of pavement renovation, and great impact of traffic, etc., and achieve good repair effect , Adhesive tightly, prevent the effect of water seepage on the road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Get 200g of coal tar pitch, 60g of toluene, 32g of xylene, 5g of butanol, 10g of polycyclic aromatic hydrocarbons, 10g of phenol, 20g of anthracene, 34g of thermoplastic acrylic resin (produced by Foshan Gaoming Tongde Chemical Co., Ltd., brand AC1024), phthalic acid Dioctyl ester 10g, calcined kaolin (specification 325 mesh) 12g, rubber powder (specification 120 mesh) 10g, calcium carbonate (specification 325 mesh) 5g, carbon black (specification 325 mesh) 5g, add in the stirring tank successively, continuously stir, Then, reflux and stir at 150°C for 4 hours, and cool to normal temperature to obtain a uniform viscous liquid mixture which is the asphalt pavement conditioning and curing agent of the present invention.

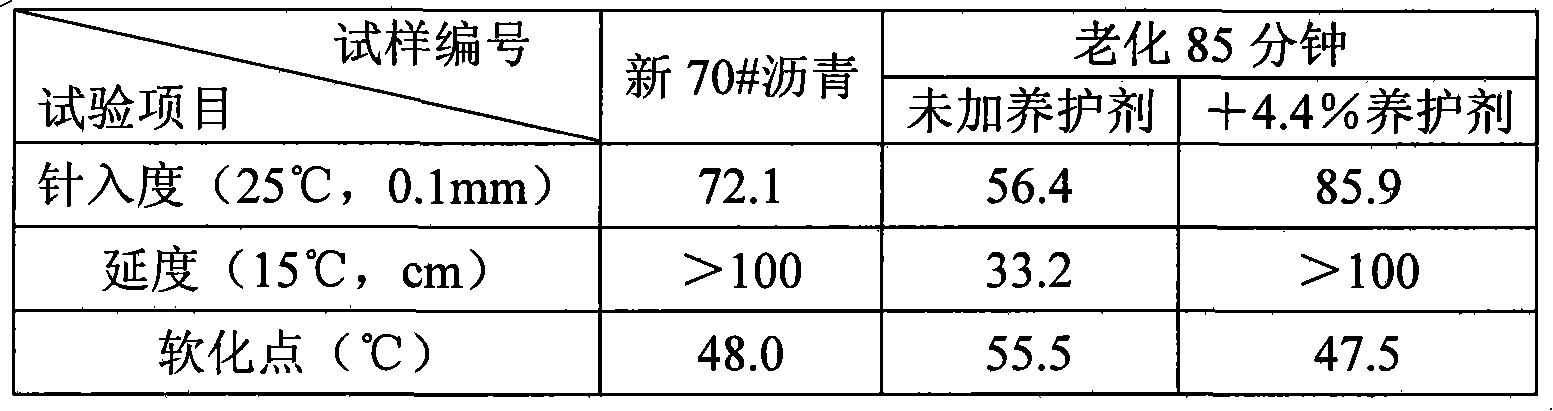

[0033] Asphalt aging regeneration test: Take 26.4g of this curing agent and mix evenly with 600g of 70# base asphalt of SK Company in Korea after 85 minutes of aging. See Table 1-1 for the index comparison of 70# base asphalt of Korea SK Company before a...

Embodiment 2

[0041] Get 140g of petroleum pitch (brand AH-70), 10g of benzene, 80g of toluene, 20g of xylene, 15g of butyl acetate, 5g of acetone, 10g of resorcinol, 40g of kerosene, 10g of naphthalene, 20g of anthracene, 20g of lubricating oil, carbon five Petroleum resin 8g, C9 petroleum resin 12g, vegetable oil 7g, dibutyl phthalate 3g, clay (325 mesh specification) 10g, montmorillonite (325 mesh specification) 8g, calcined kaolin (325 mesh specification) 5g, carbon Black (specification: 325 mesh) 2g, put into the stirring tank successively, continuously stir, then under 60 ℃, condense and reflux stir for 0.5h, cool to normal temperature, obtain uniform viscous liquid mixture which is the asphalt pavement conditioning and maintenance agent of the present invention .

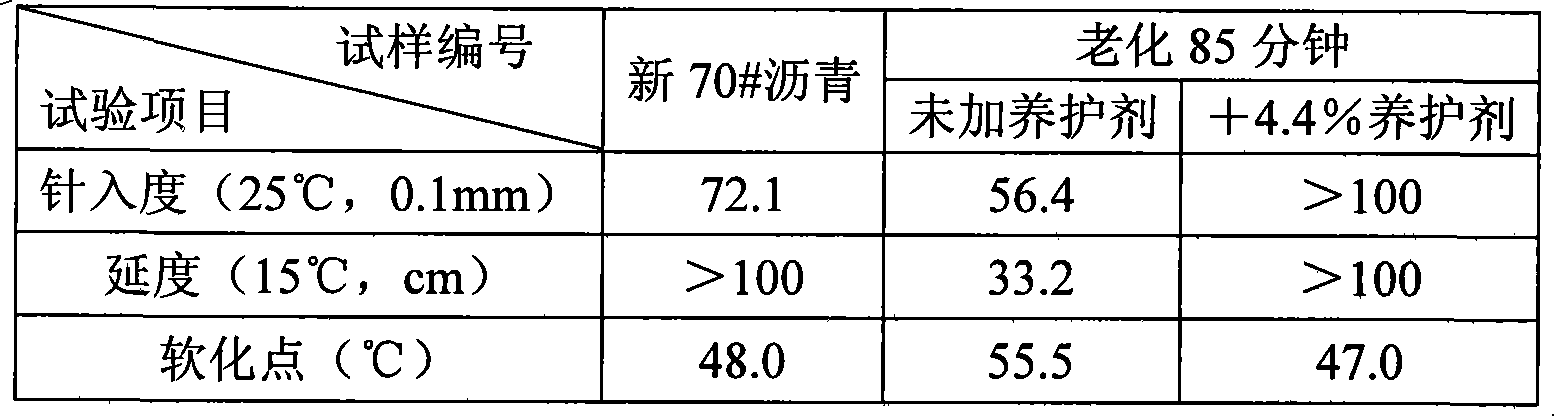

[0042] Asphalt aging regeneration test: Take 26.4g of this curing agent and mix evenly with 600g of 70# base asphalt of SK Company in Korea after 85 minutes of aging. See Table 2 for the index comparison of the 70# base a...

Embodiment 3

[0047] Get petroleum pitch (brand AH-90) 100g, thinner 120g, resorcinol 10, naphthalene 10, anthracene 20g, light mineral oil 20g, lubricating oil 20g, kerosene 30g, C9 petroleum resin 12g, silicone resin ( Polysiloxane) 5g, dibutyl phthalate 4g, clay (325 mesh specification) 10g, montmorillonite (325 mesh specification) 8g, calcined kaolin (325 mesh specification) 5g, carbon black (325 mesh specification) ) 2g, added in the stirring tank successively, continuously stirred, then condensed and refluxed and stirred for 3h at 120°C, cooled to normal temperature to obtain a uniform viscous liquid mixture which is the asphalt pavement conditioning and curing agent of the present invention.

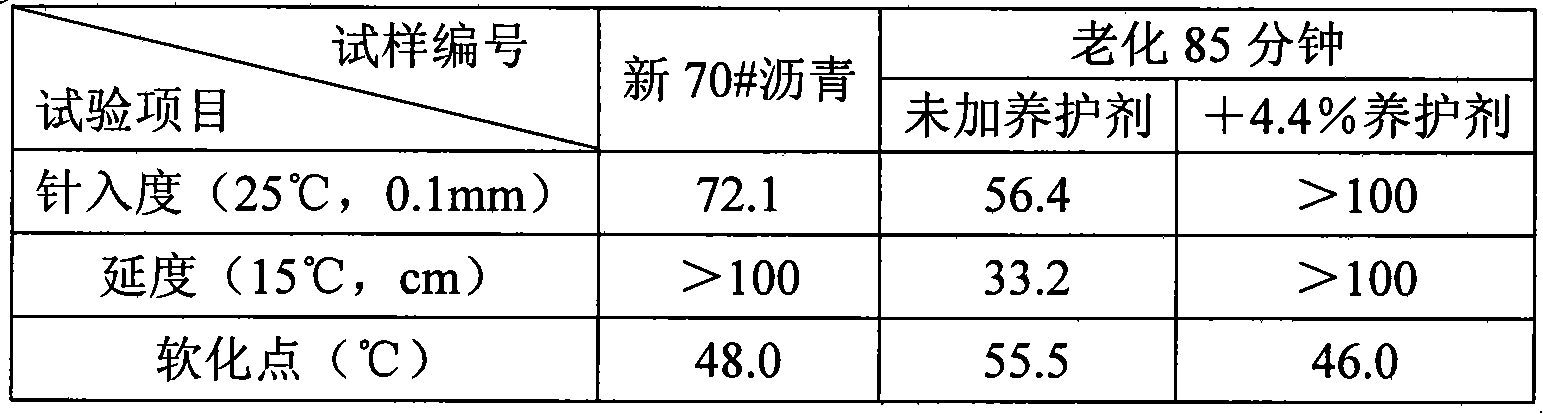

[0048] Asphalt aging regeneration test: Take 26.4g of this curing agent and mix evenly with 600g of 70# base asphalt of SK Company in Korea after 85 minutes of aging. See Table 3 for the index comparison of the 70# base asphalt of Korea SK Company before and after aging, and after adding asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com