Automobile tail gas purifier high performance nano assembly catalyze coating material and method of preparing the same

A technology for automobile exhaust gas and catalytic coating, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. and other problems, to achieve the effect of improving bulk properties, improving high temperature thermal stability, and reducing reduction temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

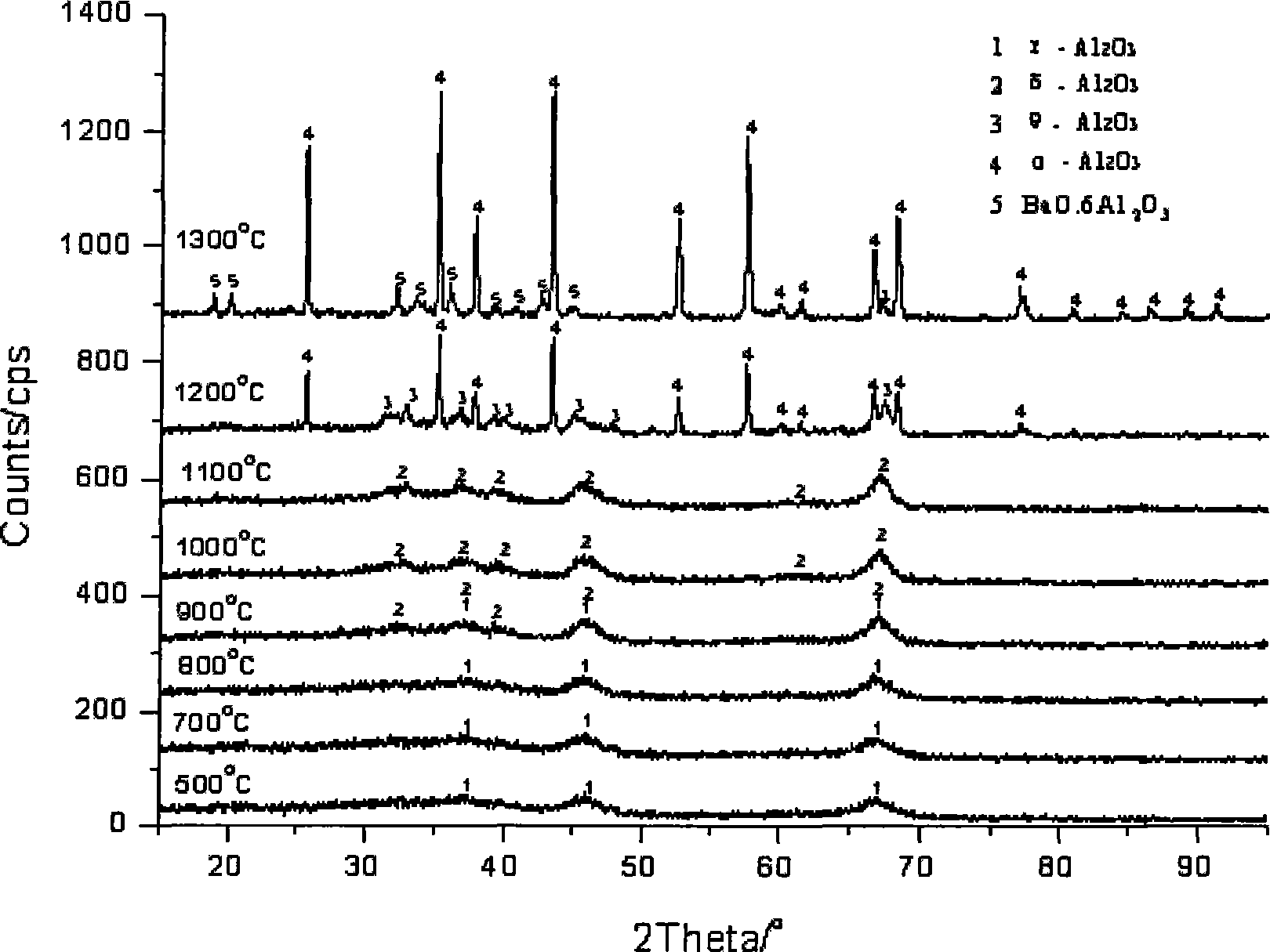

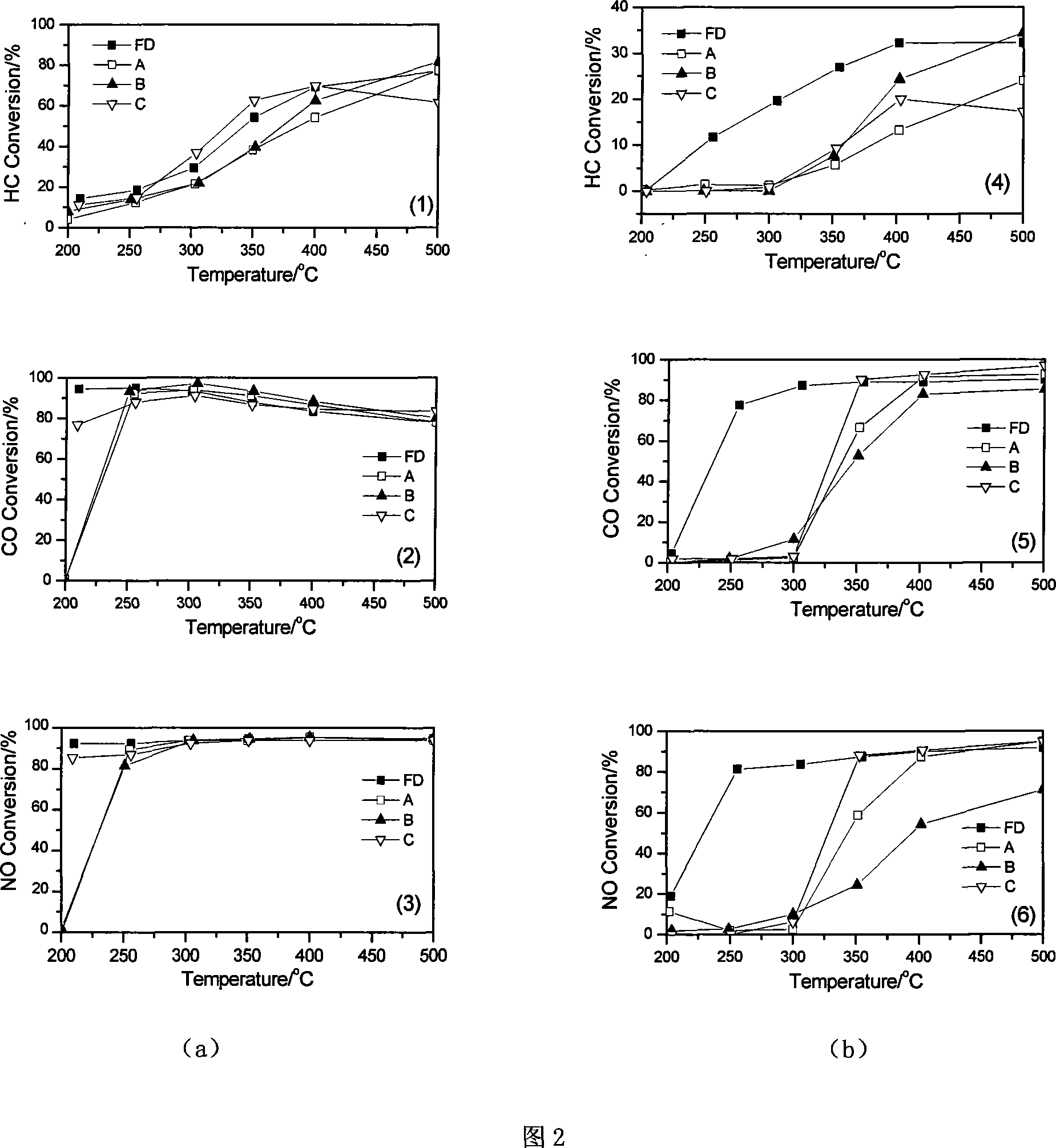

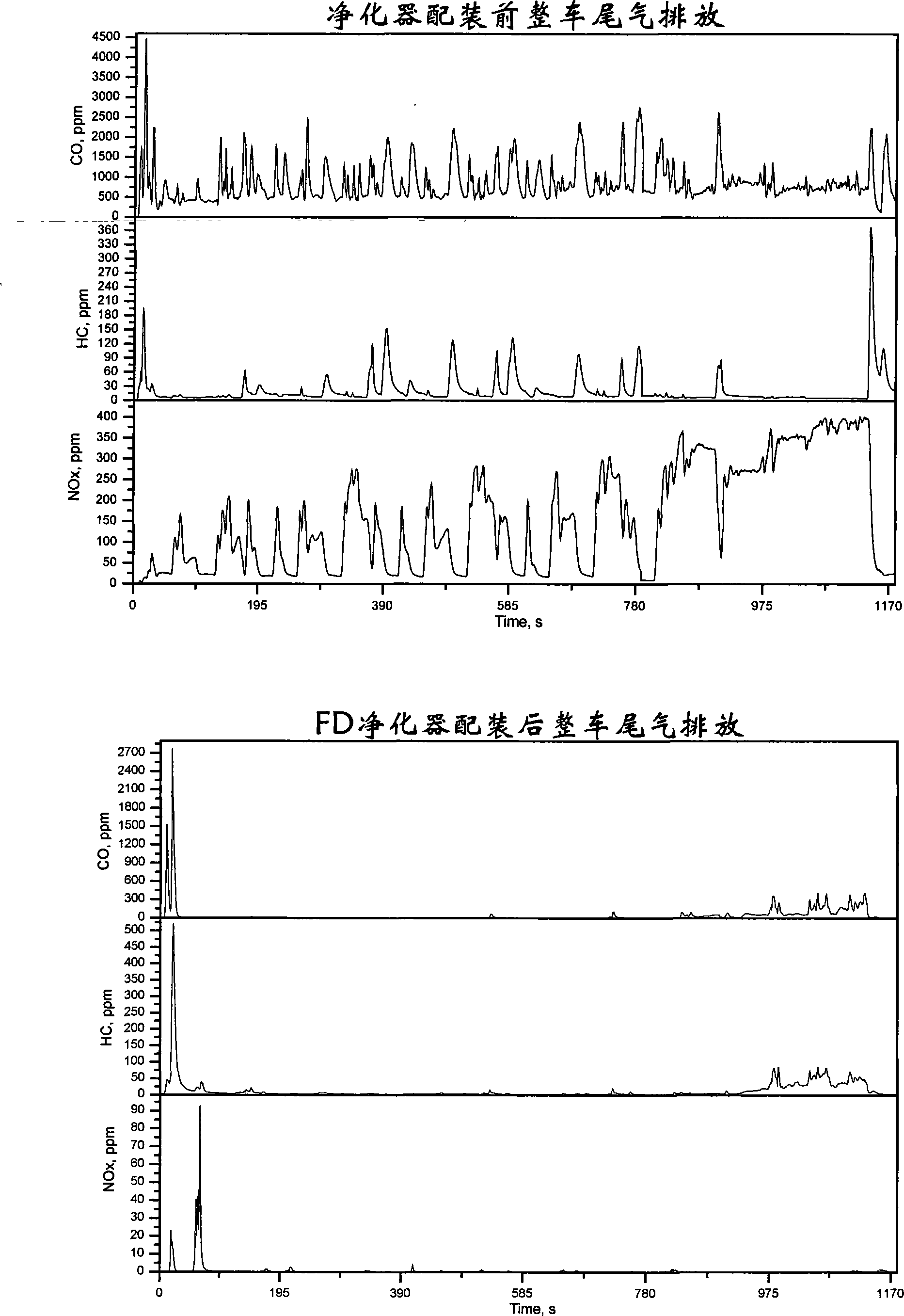

[0021] The preparation of alumina composite oxide nanomaterials is as follows: the nitrate or carbonate or oxychloride of Al, alkaline earth metal elements, transition metal elements and rare earth elements is prepared into a solution according to a certain composition ratio, and the solution is prepared at normal temperature and pressure, 100 Stirring speed of ~900rpm and in the presence of surfactants, co-precipitation or step-by-step co-precipitation with the precipitating agent, the pH value of the precipitation process is controlled at 7-10, and the stirring is continued for 3-24 hours under airtight conditions after the precipitation is completed. The obtained precipitate is filtered and washed, dried at 60-150°C, and roasted at 350-650°C for 3-5 hours. The composition ratio of the prepared alumina composite oxide nanomaterial is 60-90wt% of alumina, alkaline earth metal oxide 2-10wt% of metal oxides, 5-15wt% of transition metal oxides and 3-15wt% of rare earth oxides.

...

Embodiment 1

[0032] The preparation mass percentage is the high specific surface aluminum oxide composite oxide of 80% of alumina, 5% of cerium oxide, 2.5% of zirconia, 2% of strontium oxide, 2% of lanthanum oxide, 4% of barium oxide and 4.5% of nickel oxide by step Co-precipitation method, prepare nitrate mixed solution A containing Al, La, Ba, Ni in proportion, prepare nitrate mixed solution B containing Ce, La, Sr and Zr oxychloride mixed solution B, weigh the quality of alumina 0.3 % PVA and ammonia water with a mass concentration of 10% were made into base solution C, and PEG with a mass concentration of 0.3% of alumina was weighed, 10% ammonia water with a mass concentration of 10% ammonium carbonate was made into lye D, and solution A was added under stirring Co-precipitation is carried out in liquid C, and the pH value of the precipitation is controlled to be 7.5 to 8. After the precipitation reaction is complete, the precipitation mixture E is obtained, and then B and D are added t...

Embodiment 2

[0034] Preparation composition is Ce 0.4 Zr 0.55 La 0.04 Y 0.01 o 1.98 The cerium-zirconium composite oxide nanomaterials, first prepare the mixed solution A2 of the nitrate of Ce, La, Y and Zr oxychloride in proportion, weigh the lauric acid and the mass concentration of 1% of cerium-zirconium oxide and be 10% The urea mixture C2, mix A2 and C2 and put it in the autoclave, raise the temperature to 80°C with stirring at a rate of 2°C / min and maintain it for 2 hours, then raise it to 180°C at 0.5°C / min for coprecipitation reaction After 12 hours, the reaction pressure is about 2.5Mpa. After the reaction, the temperature is naturally lowered to below 60°C under continuous stirring to obtain a precipitated mixture, filtered and washed 3 times, dried at 115°C, and calcined at 650°C for 4 hours to obtain a cerium-zirconium composite. oxide nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com