Method for synchronously reclaiming porcelain clay and rear earth from ionic adsorption type rear earth ore

An ion-adsorption type, kaolin technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of incomplete utilization of minerals, environmental damage, etc., and achieve comprehensive utilization of associated minerals, high added value, The effect of good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A method for synchronously recovering kaolin and rare earth from ion-adsorption type rare earth ore, consisting of the following steps in sequence:

[0027] (1) mash

[0028] Mix the ion-adsorbed rare earth raw ore with water for pulping. The pulping can be carried out in the pulping tank to form a pulp with a concentration of 43% by mass. Add ammonium sulfate as a rare earth leaching agent at the same time as the pulping or before the pulping. The process makes the rare earth ions in the ion-adsorption type rare earth raw ore fully undergo ion exchange reaction with the rare earth leaching agent to form a rare earth salt, and the rare earth salt is dissolved in water, wherein the mass ratio of the rare earth leaching agent to the ion-adsorption type rare earth raw ore is 1:32 .

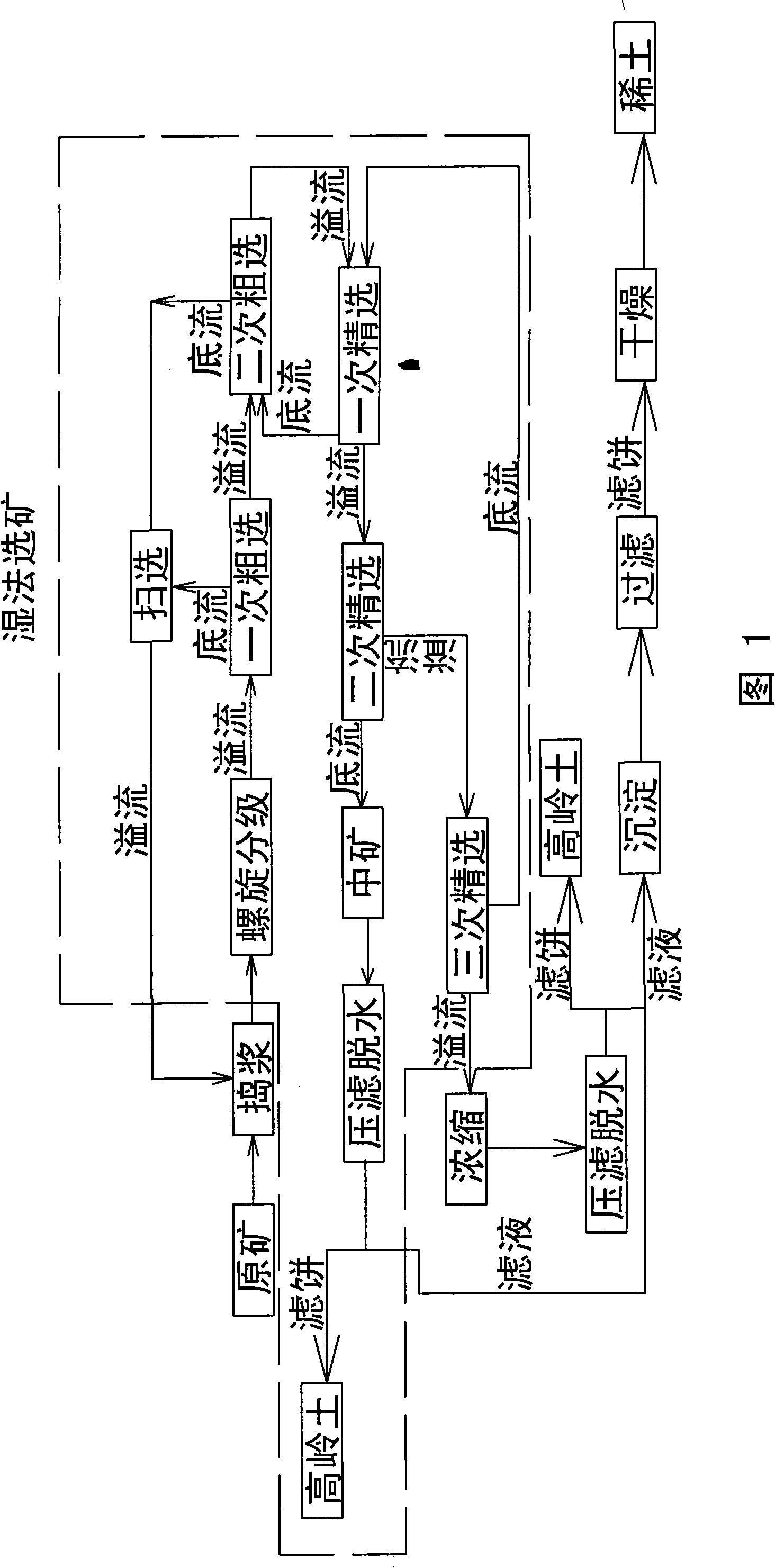

[0029] (2) wet beneficiation

[0030] The ore pulp formed by pounding is subjected to wet beneficiation. The specific process is: the ore pulp is classified by a spiral classif...

Embodiment 2

[0034] Embodiment 2. A method for synchronously recovering kaolin and rare earth from ion-adsorption type rare earth ore. The raw ore composition of the rare earth mine in Longnan County, Lintang City, Jiangxi Province: 0.009-0.01% of rare earth, 48% of kaolin, 5.49% of potassium feldspar, and sodium feldspar Stone 0.16%, mica 1.88%, quartz sand 48.25%, the chemical composition is: chemical composition SiO 2 Fe 2 o 3 al 2 o 3 SO 3 K 2 O Na 2 O CaO MgO TiO 2 IL content (%)72.73 0.88 18.52 0.38 1.10 0.06 0.10 0.11 0.28 6.05

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com