Ultra-hydrophobic surface coating material and preparation method thereof

A technology of super-hydrophobic surface and surface coating, which can be applied to devices, coatings, special surfaces, etc. for coating liquids on the surface. The method is simple, the preparation process is simple, and the effect of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

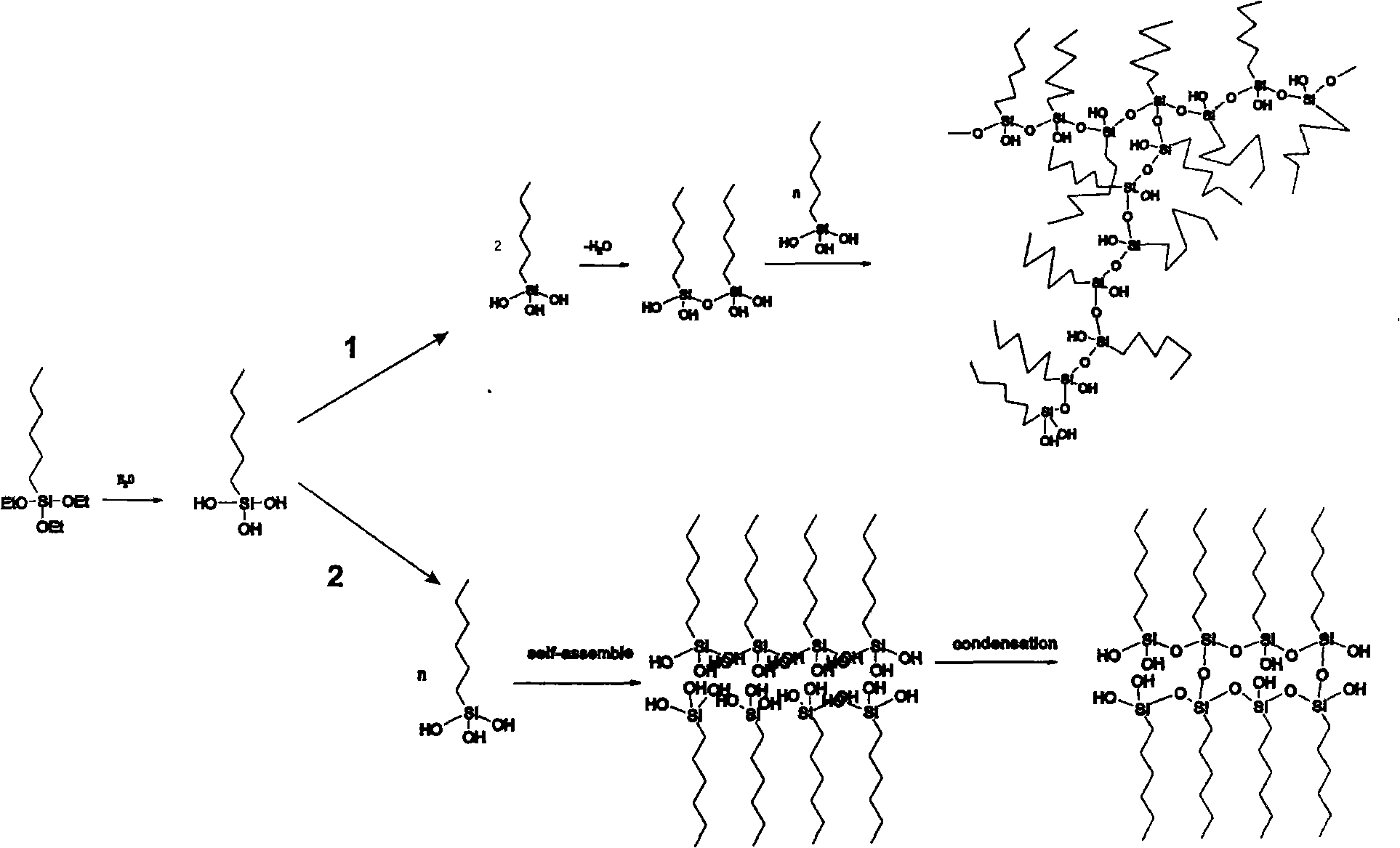

Method used

Image

Examples

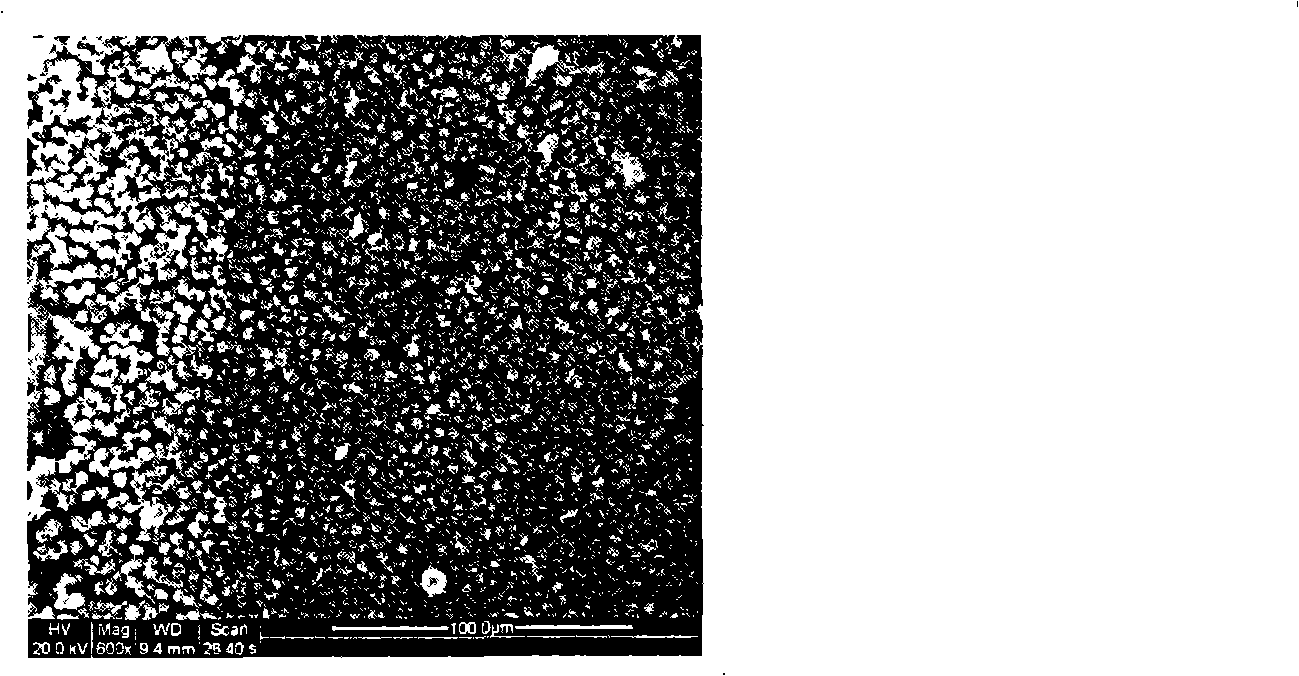

Embodiment 1

[0043] Hot piranha is prepared by mixing concentrated sulfuric acid and hydrogen peroxide in a 2:1 ratio. Immerse the clean glass piece in Piranha for activation treatment. After 45 minutes, take out the glass piece, wash it with a large amount of ultrapure water, and dry it with nitrogen gas. Toluene was used as solvent, mixed with 2% OTS solution, and the treated glass sheet was coated by immersion coating method. The coated glass sheet was dried in air for 20 seconds, immersed in acetone for 5 seconds, taken out, heat treated at 100°C for 3 hours, and left in air for 20 hours to obtain a thickness of 25 microns, a rolling angle of 3 degrees, and a contact angle of 155 degree hydrophobic membrane.

Embodiment 2

[0045] Hot piranha is prepared by mixing concentrated sulfuric acid and hydrogen peroxide in a 3:1 ratio. Immerse the clean glass piece in Piranha for activation treatment. After 45 minutes, take out the glass piece, wash it with a large amount of ultrapure water, and dry it with nitrogen gas. DTS: TEOS molar ratio = 10: 1, directly sprayed onto the silicon wafer, steamed for 50 seconds, taken out, and heat treated at 100°C to obtain a superhydrophobic material with a thickness of 15 microns, a rolling angle of 3 degrees, and a contact angle of 156 degrees. membrane.

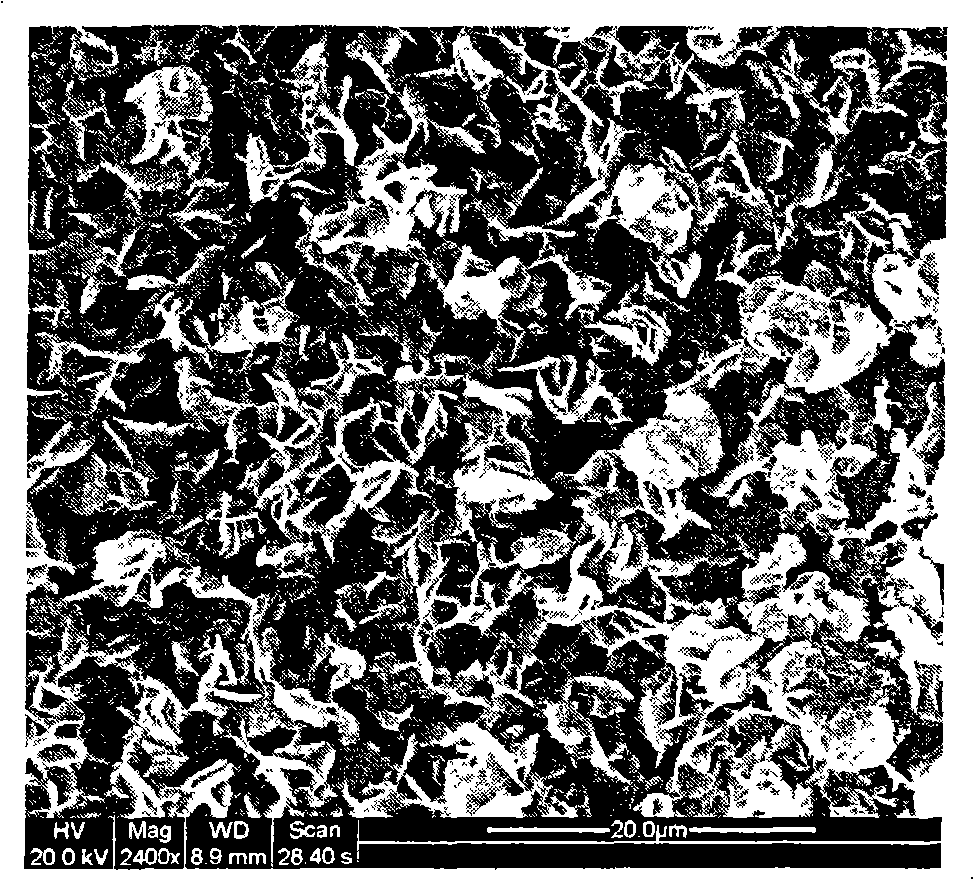

Embodiment 3

[0047] Hot piranha is prepared by mixing concentrated sulfuric acid and hydrogen peroxide in a 2:1 ratio. Immerse the clean glass piece in Piranha for activation treatment. After 45 minutes, take out the glass piece, wash it with a large amount of ultrapure water, and dry it with nitrogen gas. With ODTS: DTES molar ratio = 5: 1, the treated glass flakes were coated by immersion coating. After the coated glass sheet is dried in the air for 20 seconds, immersed in ethyl acetate for 5 seconds, taken out, heat treated at 100°C for 3 hours, and left standing in the air for 20 hours, the thickness of the coating is 25 microns, and the rolling angle is 1 degree. , a hydrophobic film with a contact angle of 176 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com