Preparation of red glass

A glass and red technology, applied in the field of preparing red glass by ion diffusion, can solve the problems such as the inability to obtain colored uniform quality red glass, the formula and process system are not given, the color of the product is inconsistent, etc. The effect of short firing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

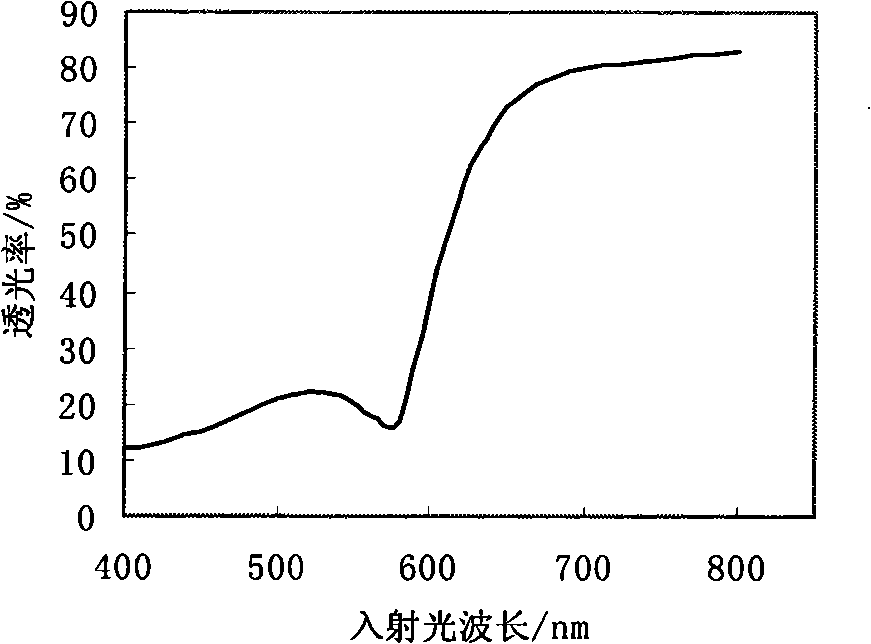

[0013] Example 1: First, clean the glass surface and dry it for use, then stir and mix water, glycerin and dextrin evenly, and then add analytically pure CuCl, SnO, FeSO 4 ·7H 2 O and pulverized coal were stirred evenly to obtain a mixed slurry, in which analytically pure CuCl:SnO:FeSO 4 ·7H 2 O: water: glycerol: dextrin: the mass ratio of pulverized coal is 12:5:6:10:3:2:2; secondly, pour the mixed slurry into a ball mill jar and ball mill for 3 hours and pass through a 200 mesh sieve, finally , apply the sieved slurry evenly (spraying method can be used) on the cleaned glass surface (it can be applied on both sides), and after the slurry is naturally dried, put it into the muffle furnace, and transfer it from the chamber at a rate of 3°C / min. Raise the temperature to 400°C and keep it warm for 30 minutes; then raise the temperature to 580°C at a rate of 5°C / min and keep it warm for 10 minutes. Excess copper salts are washed off to obtain red glass with a smooth surface. ...

Embodiment 2

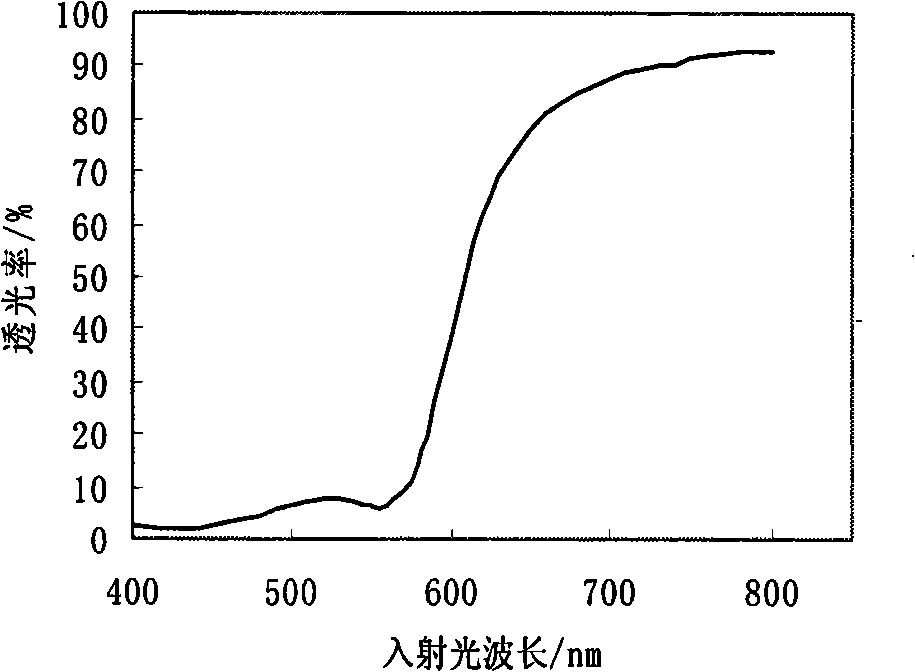

[0014] Example 2: First, clean the glass surface and dry it for use, then stir and mix water, glycerin and dextrin evenly, and then add analytically pure CuCl, SnO, FeSO 4 ·7H 2 O and pulverized coal were stirred evenly to obtain a mixed slurry, in which analytically pure CuCl:SnO:FeSO 4 ·7H 2 O: water: glycerol: dextrin: the mass ratio of pulverized coal is 10:5:7:8:4:2:2; secondly, pour the mixed slurry into a ball mill jar and ball mill for 4 hours and pass through a 250 mesh sieve, finally , apply the sieved slurry evenly (spraying method can be used) on the cleaned glass surface (it can be applied on both sides), and after the slurry is naturally dried, put it into the muffle furnace, and transfer it from the chamber at a rate of 3°C / min. Raise the temperature to 400°C and keep it warm for 30 minutes; then raise the temperature to 600°C at a rate of 8°C / min and keep it warm for 5 minutes, then turn off the power, let the glass cool down to below 50°C with the furnace te...

Embodiment 3

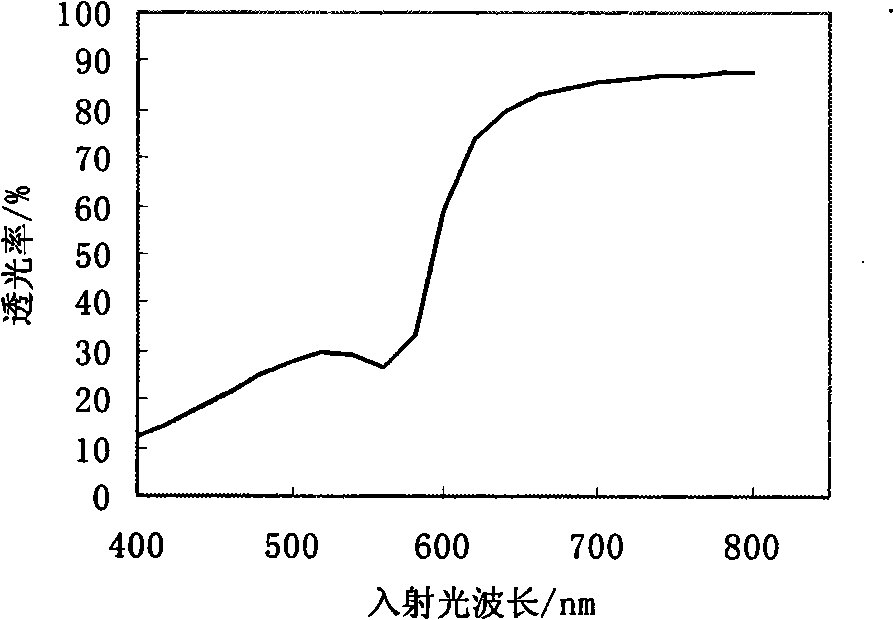

[0015] Example 3: First, clean the glass surface and dry it for use, then stir and mix water, glycerin and dextrin evenly, and then add analytically pure CuCl, SnO, FeSO 4 ·7H 2 O and pulverized coal were stirred evenly to obtain a mixed slurry, in which analytically pure CuCl:SnO:FeSO 4 ·7H 2 O: water: glycerol: dextrin: the mass ratio of pulverized coal is 14:5:5:10:1:1:1; secondly, pour the mixed slurry into a ball mill jar and ball mill for 5 hours and pass through a 300 mesh sieve, finally , apply the sieved slurry evenly (spraying method can be used) on the cleaned glass surface (it can be applied on both sides), and after the slurry is naturally dried, it is put into the muffle furnace, and is heated from the chamber at a rate of 5°C / min. Raise the temperature to 400°C and keep it warm for 30 minutes; then raise the temperature to 580°C at a rate of 7°C / min and keep it warm for 25 minutes. Excess copper salts are washed off to obtain red glass with a smooth surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com