Dacron hydrophilic antistatic agent, preparing method and dacron afterfinish method

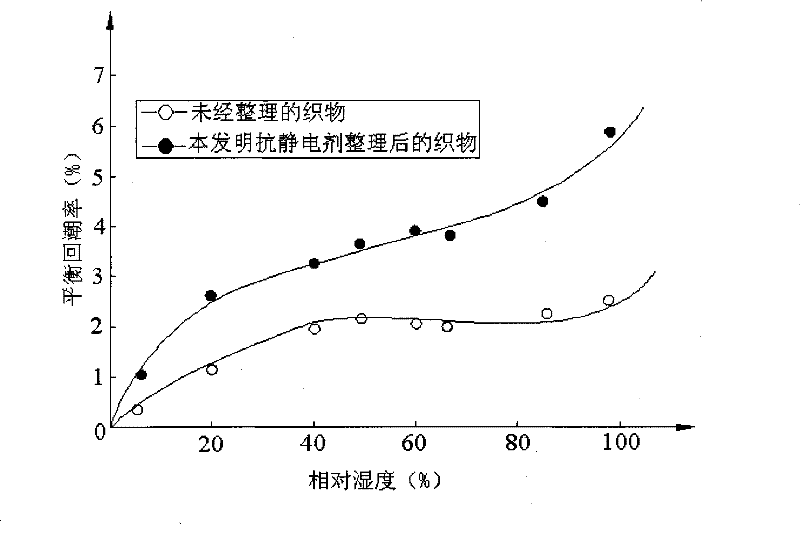

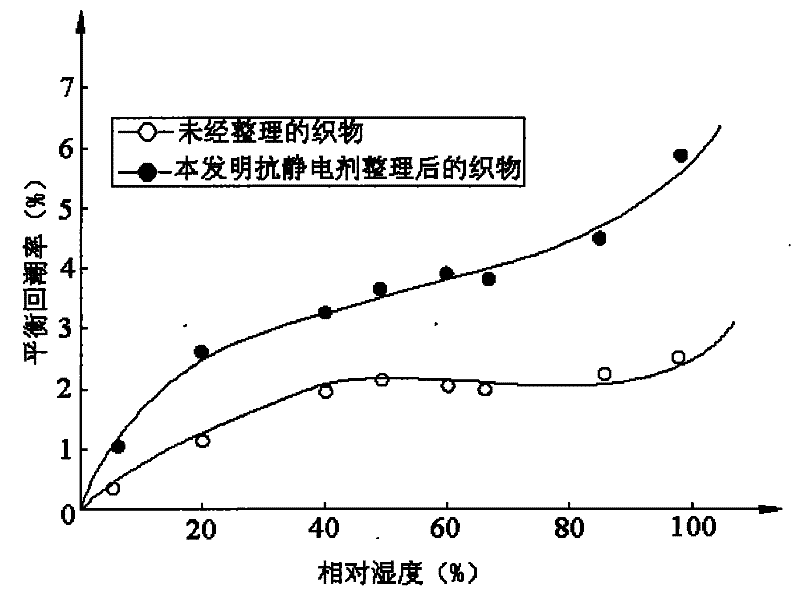

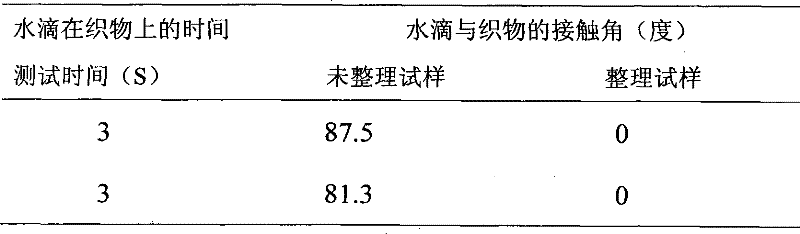

An antistatic agent and technology for polyester fabrics, applied in the fields of hydrophilic antistatic agents for polyester fabrics, finishing polyester fabrics and antistatic agents, can solve the problems of complex chemical preparation methods, high requirements for production equipment, environmental pollution, etc. Dyeing and finishing production cost, meeting simulation requirements, and the effect of simplifying finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of hydrophilic antistatic agent of the present invention, carries out according to the following steps:

[0044] Step 1: According to mass percentage, take 8%-18% of dimethyl terephthalate, 38%-48% of ethylene glycol, 16%-26% of polyethylene glycol, 6%-16% of zinc acetate, three 4% to 14% of antimony oxide and 3% to 8% of triphenyl phosphate;

[0045] Step 2: Perform transesterification

[0046] The dimethyl phthalate, ethylene glycol and polyethylene glycol obtained in step 1 are mixed and heated to a molten state, stirred to form a molten liquid, and the zinc acetate and antimony trioxide weighed in step 1 are added to the molten liquid respectively. Halfway, when the temperature of the molten liquid is 80°C to 130°C, nitrogen gas is introduced to protect the molten liquid, and the heating is continued to raise the temperature of the molten liquid to 150°C to 195°C, and the reaction is 5h to 8h. During the reaction, acid The gaseous product-me...

Embodiment 1

[0057] According to mass percentage, dimethyl terephthalate 8%, ethylene glycol 48%, polyethylene glycol 16%, zinc acetate 11%, antimony trioxide 14% and triphenyl phosphate 3%, each group The total amount of the ingredients is 100%; dimethyl phthalate, ethylene glycol and polyethylene glycol are mixed and heated to a molten state, stirred to form a molten liquid, and 5.5% of zinc acetate and antimony trioxide are added to the molten liquid 7%, when the temperature of the molten liquid is 80°C, feed nitrogen gas to protect the molten liquid, continue heating, so that the temperature of the molten liquid rises to 150°C, and react for 5 hours. During the reaction, an acid burette is used to collect the methanol produced by the reaction Gas, the amount of methanol in the acid burette stops increasing, that is, the transesterification is completed, and the reacted product is protected by nitrogen at 80°C, and left for 3 hours to obtain the transesterified product; triphenyl phospha...

Embodiment 2

[0060] According to mass percentage, dimethyl terephthalate 13%, ethylene glycol 43%, polyethylene glycol 26%, zinc acetate 6%, antimony trioxide 4% and triphenyl phosphate 8%, each group The total amount of points is 100%; dimethyl phthalate, ethylene glycol and polyethylene glycol are mixed and heated to a molten state, stirred to form a molten liquid, and 3% zinc acetate and 2% zinc acetate are added to the molten liquid respectively. Antimony trioxide, when the temperature of the molten liquid is 105°C, nitrogen gas is introduced to protect the molten liquid, and the heating is continued to raise the temperature of the molten liquid to 172°C, and the reaction is for 6 hours. During the reaction, an acid burette is used to collect the reaction product methanol, the amount of methanol in the acid burette stopped increasing, and the transesterification was completed. The product after the reaction was protected by nitrogen at 105°C and left for 4 hours to obtain the transester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com