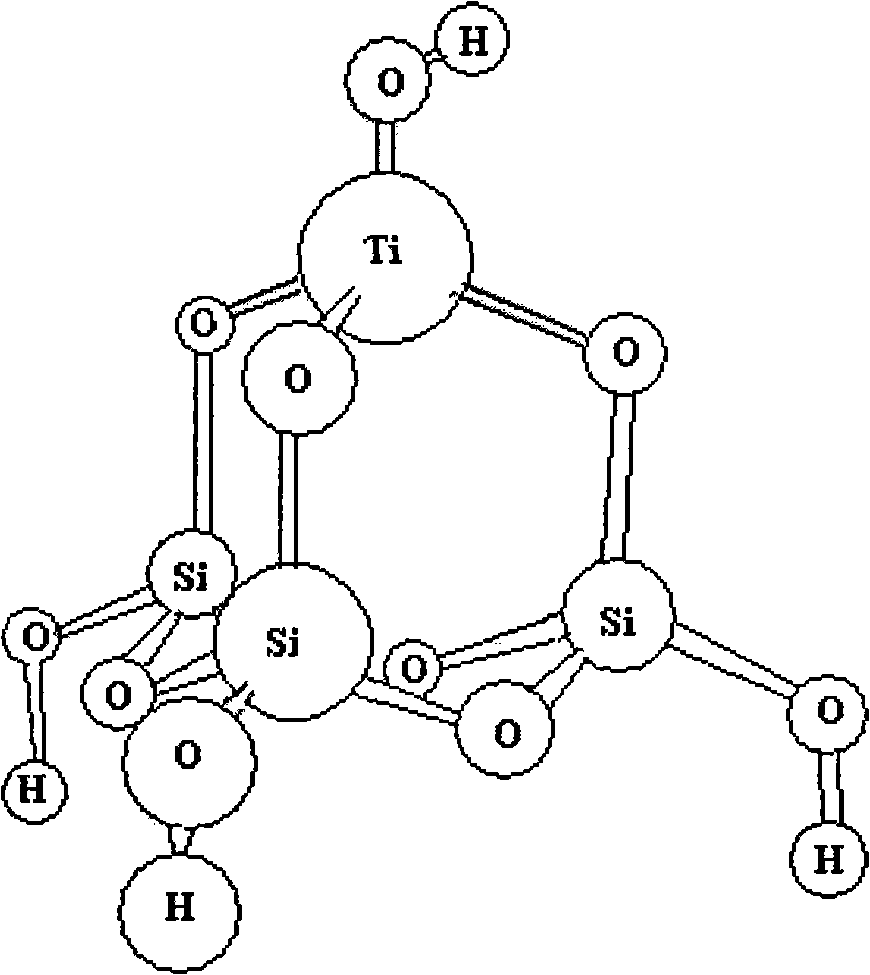

Composite aerogel photocatalyst for recovering titanium dioxide/silicon dioxide

A composite aerogel, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. It can achieve the effect of easy recycling, high photocatalytic activity and uniform pore distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

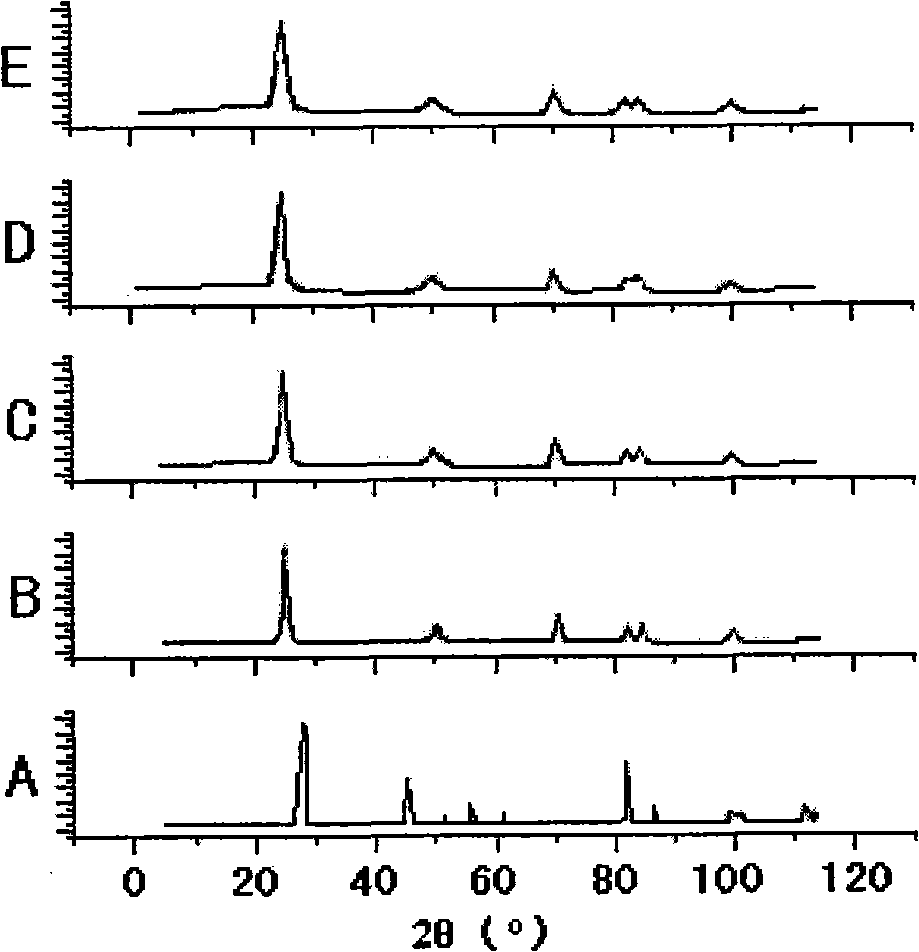

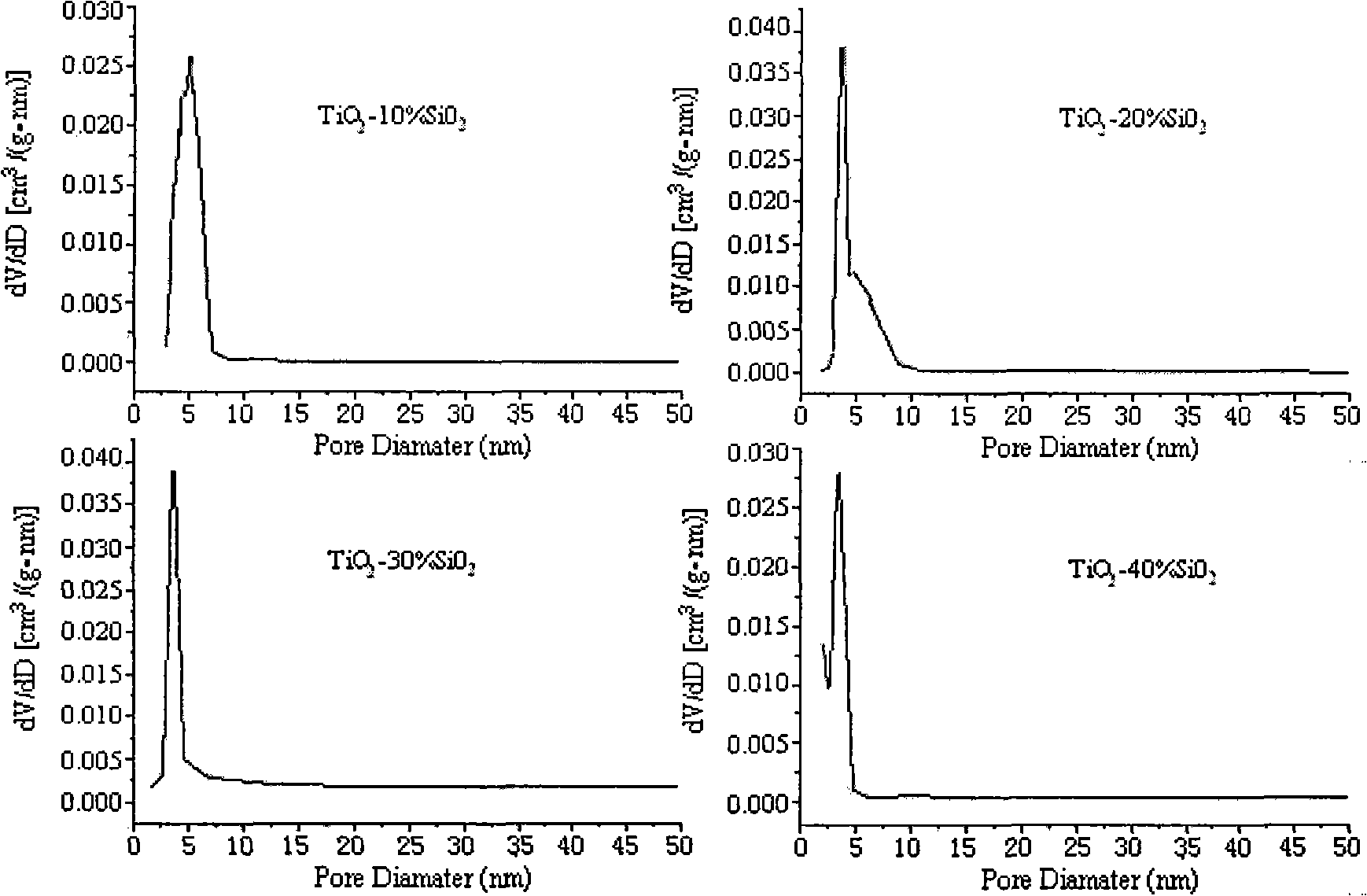

Embodiment 1

[0037] (1) Take 5ml of tetraethyl orthosilicate and pour it into a beaker, then pour 6.5ml of absolute ethanol into the beaker, stir while pouring, then add 1.2ml of deionized water, and finally adjust the pH value of the mixed solution with nitric acid is 0.6. First let the above solution be hydrolyzed at a constant temperature of 80°C for 30 minutes, and then let it stand for further hydrolysis.

[0038] (2) Evenly mix 23ml of butyl titanate and 34.5ml of absolute ethanol, add dropwise 1.61ml of formamide, adjust the pH of the solution to 1 with nitric acid, and obtain solution 1; mix 23ml of absolute ethanol and 2.8ml of Mix deionized water evenly in a certain proportion, and adjust the pH of the solution to 0.6 with nitric acid to obtain solution 2. Under the strong stirring of a magnetic stirrer, slowly add solution 2 to solution 1 with a dropper at room temperature at a speed of about 90 drop / min, and continue to stir for 1-2min to make the solution evenly mixed to obta...

Embodiment 2

[0041] (1) Take out 2.52ml of tetraethyl orthosilicate and pour it into a beaker, then pour 3.28ml of absolute ethanol into the beaker, stir while pouring, then add 0.6ml of deionized water, and finally adjust the pH of the mixed solution with nitric acid The value is 0.8. First let the above solution be hydrolyzed at a constant temperature of 80°C for 40 minutes, and then let it stand for further hydrolysis.

[0042] (2) Evenly mix 26ml of butyl titanate and 39.5ml of absolute ethanol, add dropwise 1.56ml of formamide, adjust the pH of the solution to 0.8 with nitric acid, and obtain solution 1; mix 26ml of absolute ethanol and 3.25ml of Mix deionized water evenly in a certain proportion, and adjust the pH of the solution to 0.8 with nitric acid to obtain solution 2. Under the strong stirring of a magnetic stirrer, slowly add solution 2 to solution 1 with a dropper at room temperature at a speed of about 90 drop / min, and continue to stir for 1-2min to make the solution evenl...

Embodiment 3

[0045] (1) Take out 10ml of tetraethyl orthosilicate and pour it into a beaker, then pour 13ml of absolute ethanol into the beaker, stir while pouring, then add 2.4ml of deionized water, and finally adjust the pH value of the mixed solution with nitric acid 0.6. First let the above solution be hydrolyzed at a constant temperature of 80°C for 40 minutes, and then let it stand for further hydrolysis.

[0046] (2) Evenly mix 26ml of butyl titanate and 39.5ml of absolute ethanol, add dropwise 1.56ml of formamide, adjust the pH of the solution to 0.6 with nitric acid, and obtain solution 1; mix 26ml of absolute ethanol and 3.25ml of Mix deionized water evenly in a certain proportion, and adjust the pH of the solution to 1.0 with nitric acid to obtain solution 2. Under the strong stirring of a magnetic stirrer, slowly add solution 2 to solution 1 with a dropper at room temperature at a speed of about 90 drop / min, and continue to stir for 1-2min to make the solution evenly mixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com