Starch graft acrylic acid/modified verdelite high-water-absorption resin and preparing method thereof

A technology of superabsorbent resin and starch grafting, which is applied in the field of superabsorbent resin and its preparation, can solve the problems of poor salt resistance, low gel strength, and poor thermal stability of the product, and achieve stable reaction, high gel strength, and thermal stability. good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

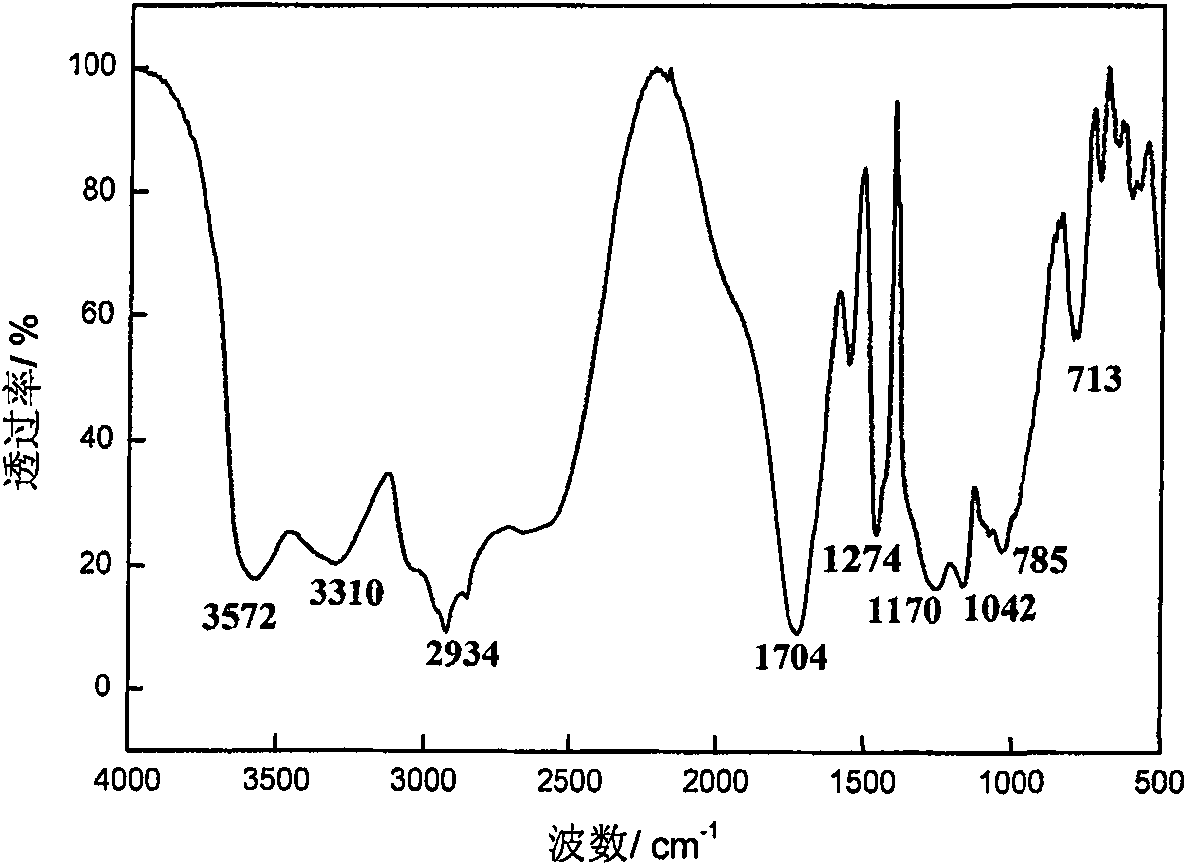

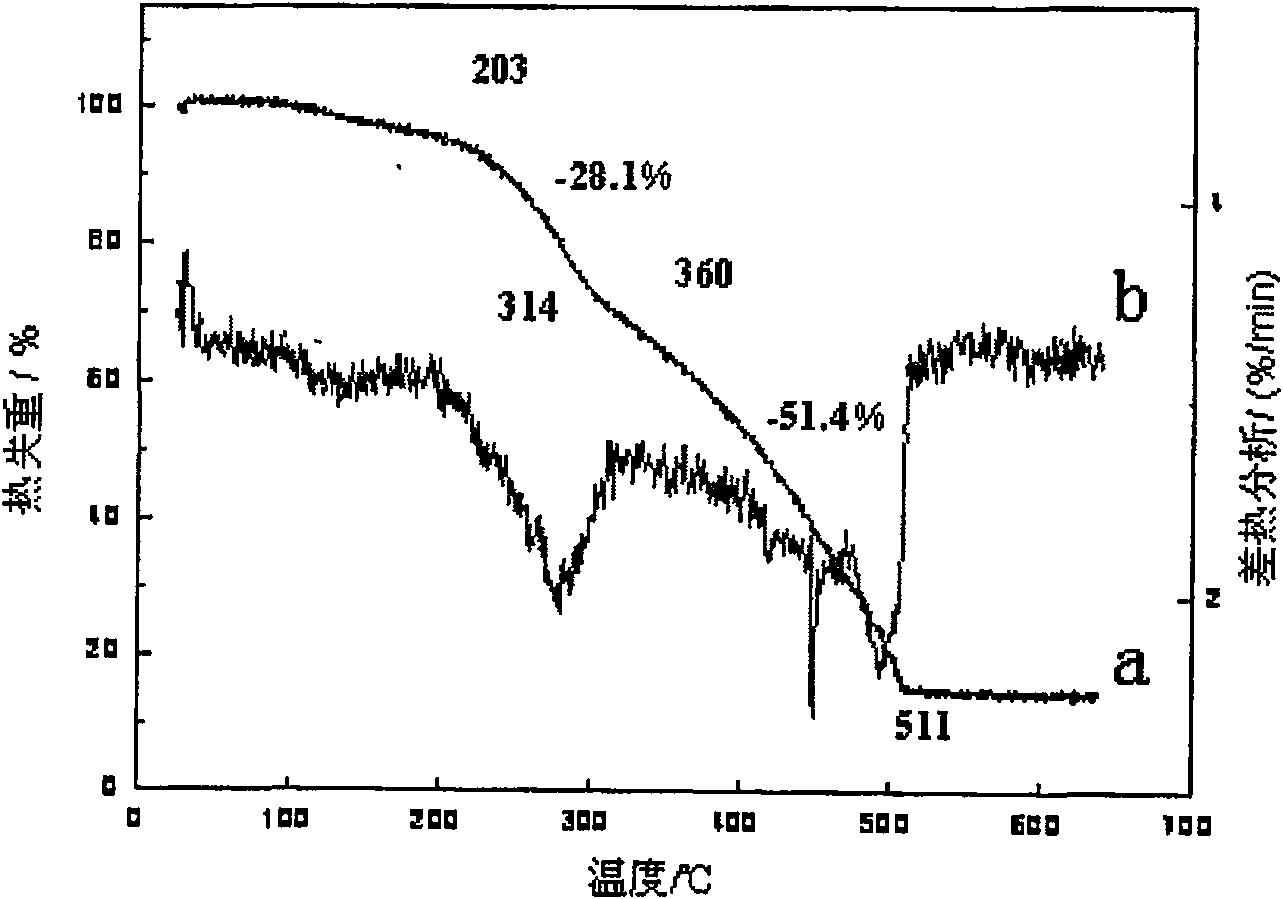

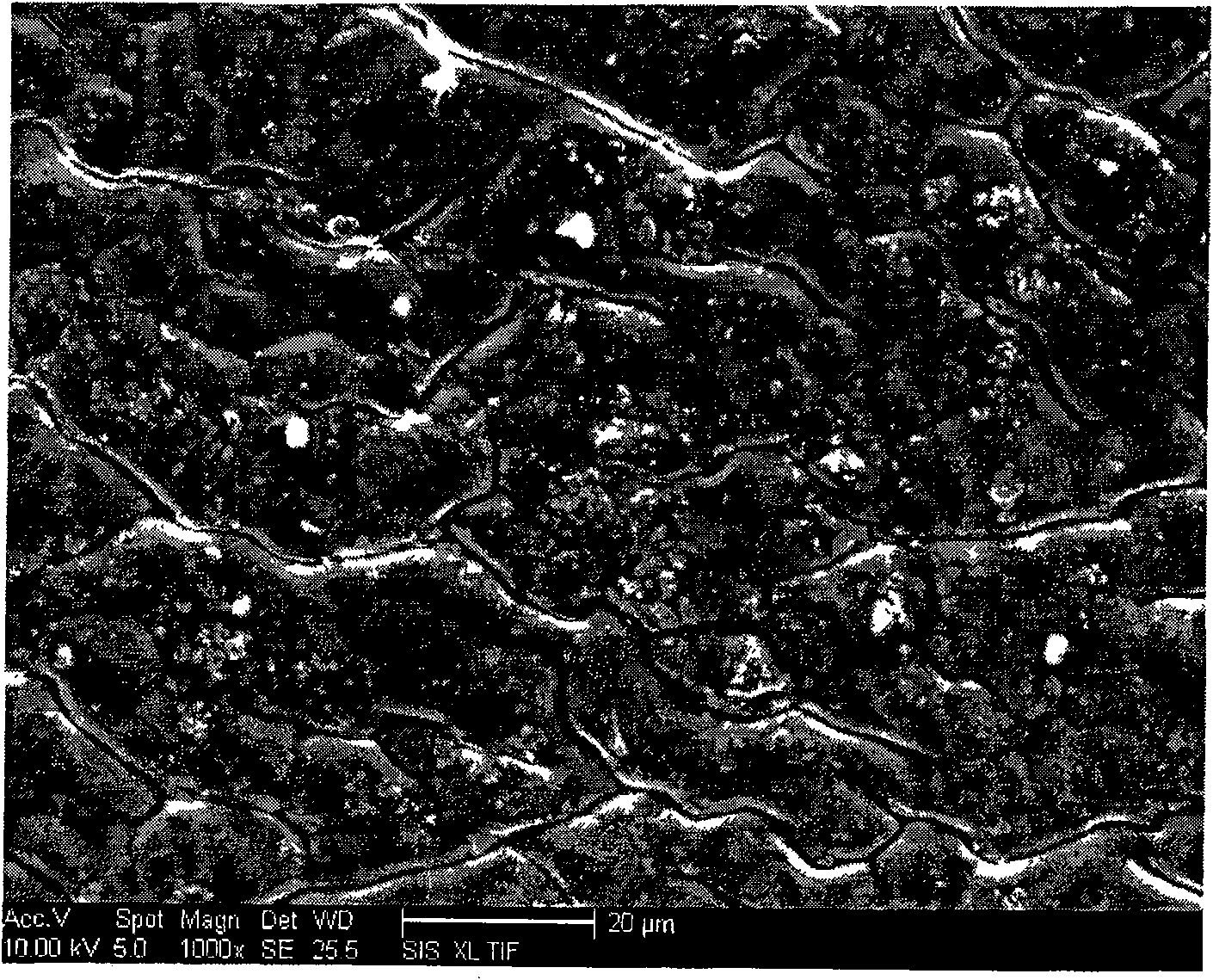

[0010] Specific embodiment 1: In this embodiment, starch-grafted acrylic acid / modified tourmaline superabsorbent resin consists of 100 parts of ethylenic monomer, 20-40 parts of starch, 0.1-2.0 parts of cross-linking agent, 0.5-2.5 20-40 parts of initiator, 20-40 parts of modified tourmaline powder and 20-40 parts of deionized water; the ethylenic monomer is acrylic acid monomer or acrylamide; the cross-linking agent is N, N-methylenebisacrylamide , epichlorohydrin or ethylene glycol diglycidyl ether; the initiator is ammonium persulfate-sodium sulfite, ammonium persulfate, ammonium persulfate-sodium bisulfite, cerium ammonium nitrate, 2,2-dimethoxyphenyl Acetophenone, benzophenone or 2,4,6-triylbenzoyl-diphenylphosphine oxide; the modified tourmaline powder is PVA modified tourmaline powder, CTAB modified tourmaline powder or stearic acid modified tourmaline powder.

specific Embodiment approach 2

[0011] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the starch-grafted acrylic acid / modified tourmaline superabsorbent resin consists of 100 parts of ethylenic monomer, 30 parts of starch, and 1.0 part of crosslinking agent according to the ratio of parts by mass. , 1.5 parts of initiator, 30 parts of modified tourmaline powder and 30 parts of deionized water. Others are the same as in the first embodiment.

[0012] All chemical reagents used in this embodiment are of analytical grade.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 1 in that the starch comes from wheat flour, barley flour, corn flour, rice flour, cassava flour, potato flour or sweet potato flour. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com