Colophony based functional polymer immobilization diastase and preparation method thereof

A technology of functional polymer and amylase, which is applied in the direction of fixing on/in the organic carrier, to achieve the effect of easy-to-obtain raw materials, low price and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

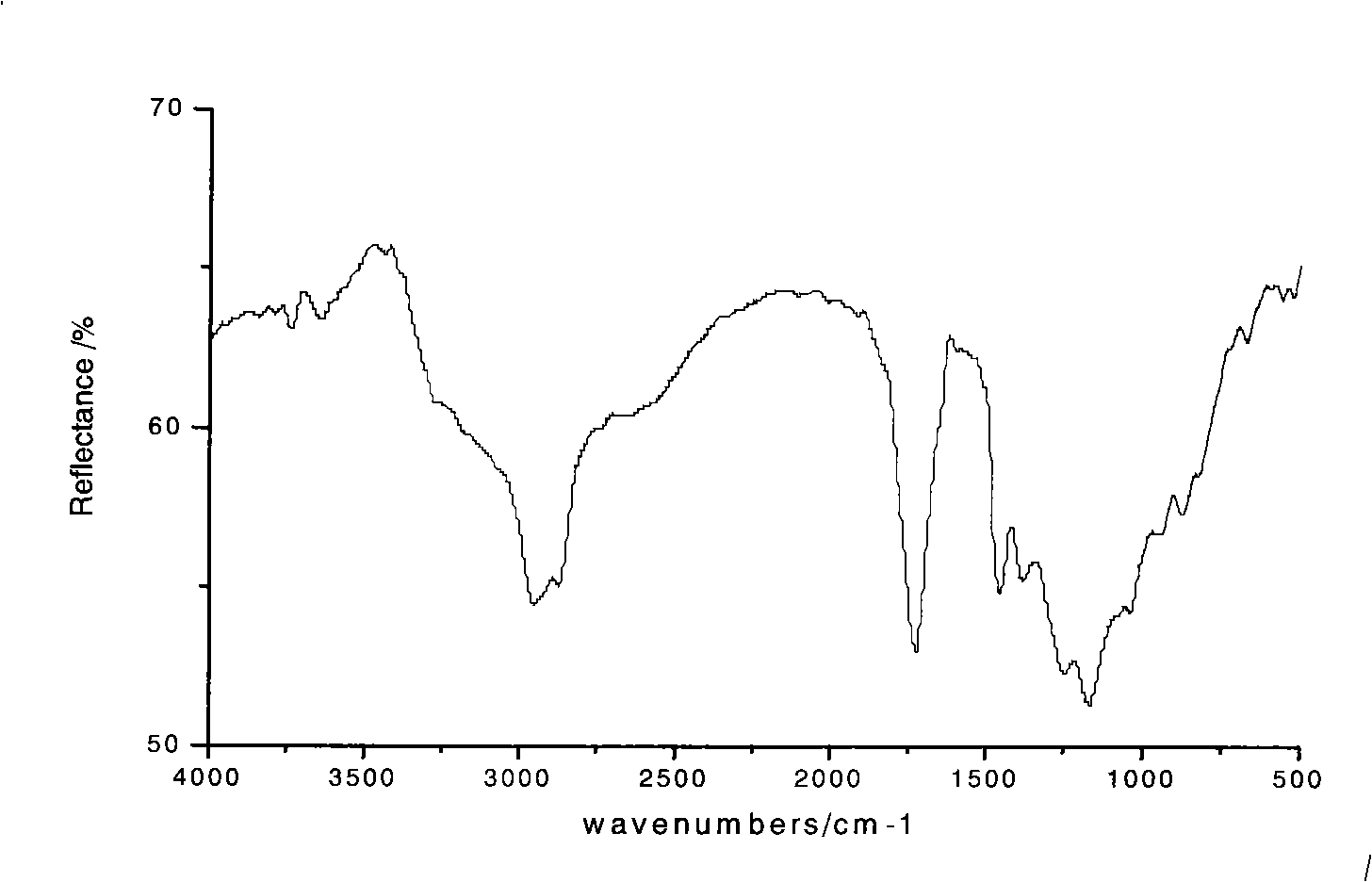

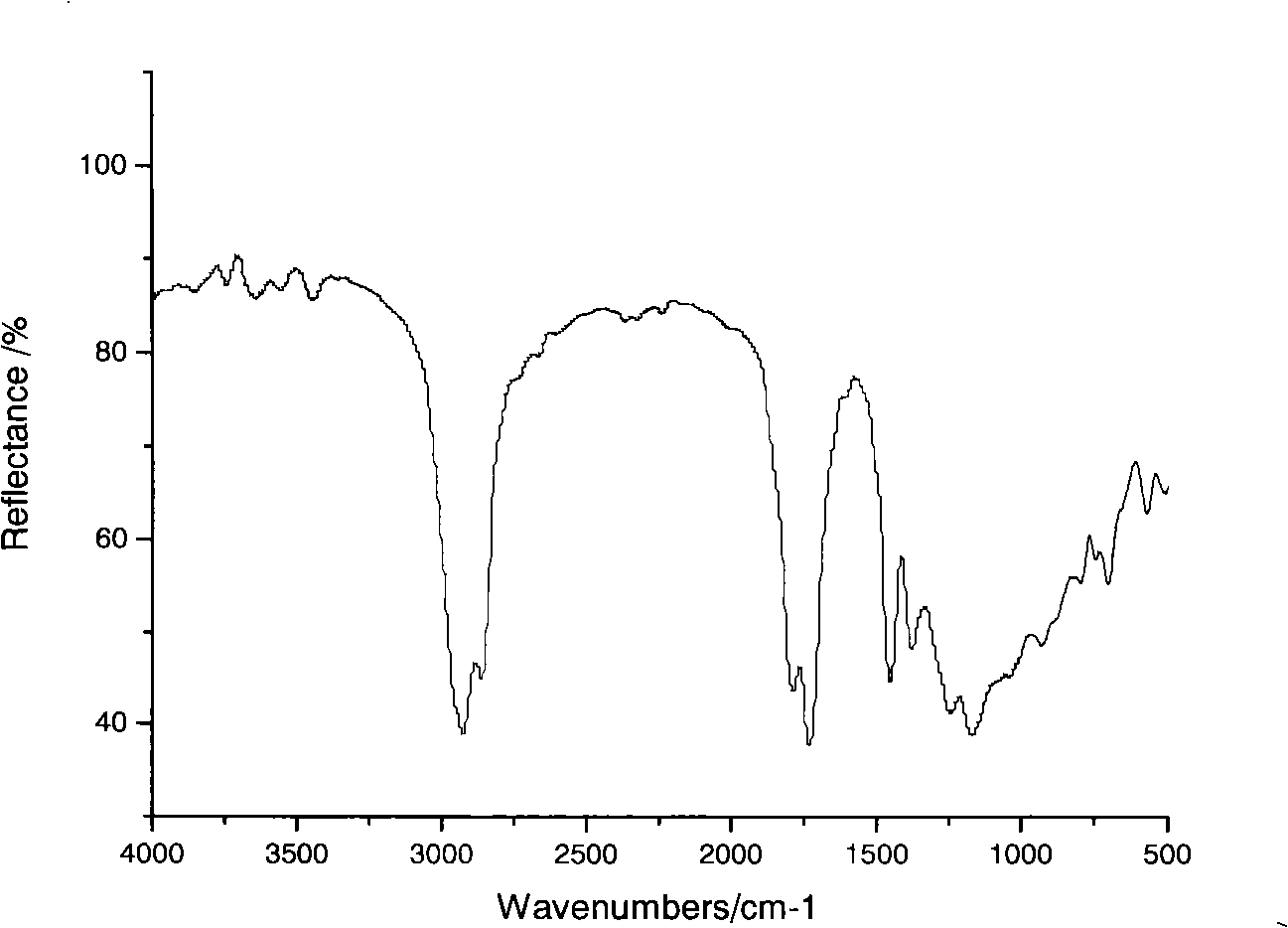

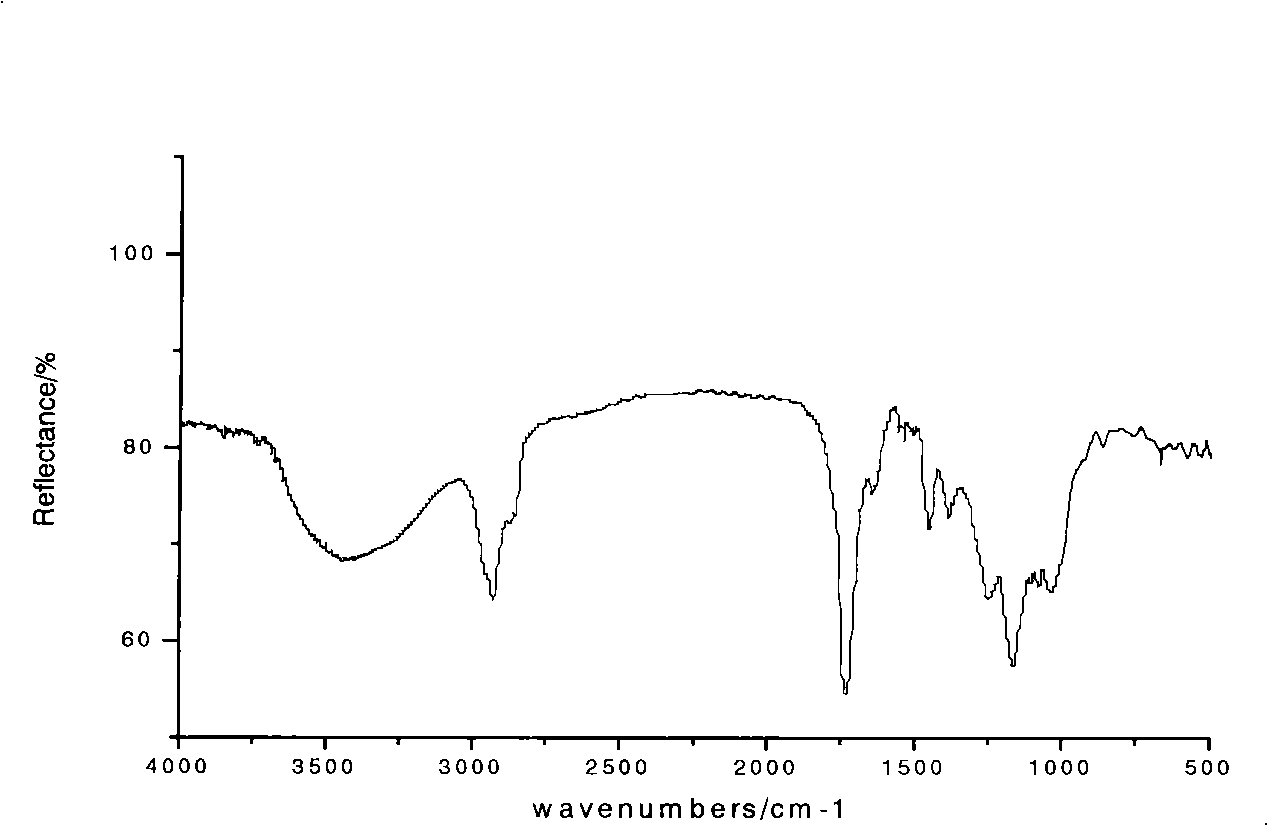

Image

Examples

Embodiment 1

[0052] Weigh 15g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer, soak the acrylic resin with cyclohexane for 24h, and filter. Place it in a three-necked bottle and add 30ml of cyclohexane. Slowly add 15ml of SOCl to the three-necked flask with a constant pressure funnel 2 , Stir, about 1h drop. Heating to raise the temperature, the temperature is controlled at 75-80°C, and refluxed for 7 hours. After the reaction is over, change the distillation device to steam out excess SOCl 2 and cyclohexane. Finally, the acylated resin was washed 3 times with 20 ml of cyclohexane each time. Maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylated resin was obtained.

[0053] Weigh 10 g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylation resin, add 40 ml of cyclohexane and 50 ml of 3% amylase solution. Stir the solution with magnetic stirring for about 10 h, and operate under dry conditions during the whole process. Wash and filter ...

Embodiment 2

[0055] Weigh 40g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer, soak the acrylic resin with cyclohexane for about 1 day, and filter. Place it in a three-necked bottle and add 50ml of cyclohexane. Slowly add 25ml of SOCl to the three-necked flask with a constant pressure funnel 2 , stirring, about 1.5h dripping. Heating to raise the temperature, the temperature is controlled at 75-80°C, and refluxed for 7 hours. After the reaction is over, change the distillation device to steam out excess SOCl 2 and cyclohexane. Finally, the acylated resin was washed 3 times with 30 ml of cyclohexane each time. Maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylated resin was obtained.

[0056] Weigh 20g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylation resin, add 40ml of cyclohexane and 60ml of 4% amylase solution. Stir the solution with magnetic stirring for about 12 hours, and operate under dry conditions during the whole process...

Embodiment 3

[0058] Weigh 60g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer, soak the acrylic resin with cyclohexane for about 1 day, and filter. Place it in a three-necked bottle and add 50ml of cyclohexane. Slowly add 35ml of SOCl to the three-necked flask with a constant pressure funnel 2 , Stir, about 2h drop. Heating to raise the temperature, the temperature is controlled at 75-80°C, and refluxed for 8h. After the reaction is over, change the distillation device to steam out excess SOCl 2 and cyclohexane. Finally, the acylated resin was washed 3 times with 50 ml of cyclohexane each time. Maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylated resin was obtained.

[0059] Weigh 30g of maleic rosin ethylene glycol acrylate-acrylic acid copolymer acylation resin, add 50ml of cyclohexane and 70ml of 5% amylase aqueous solution. Stir the solution with magnetic stirring for about 5 hours, and operate under dry conditions throughout the process. Wash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com