Process for preparing cefixime

A technology for cefixime and cefixime methyl ester, which is applied in the field of preparation of cefixime, can solve the problems of inability to recover mercaptobenzothiazole well, the use of deprotection agents is toxic, and the production cost is low, and achieves hydrolysis and crystallization. And the effect of improving the quality of finished products, reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

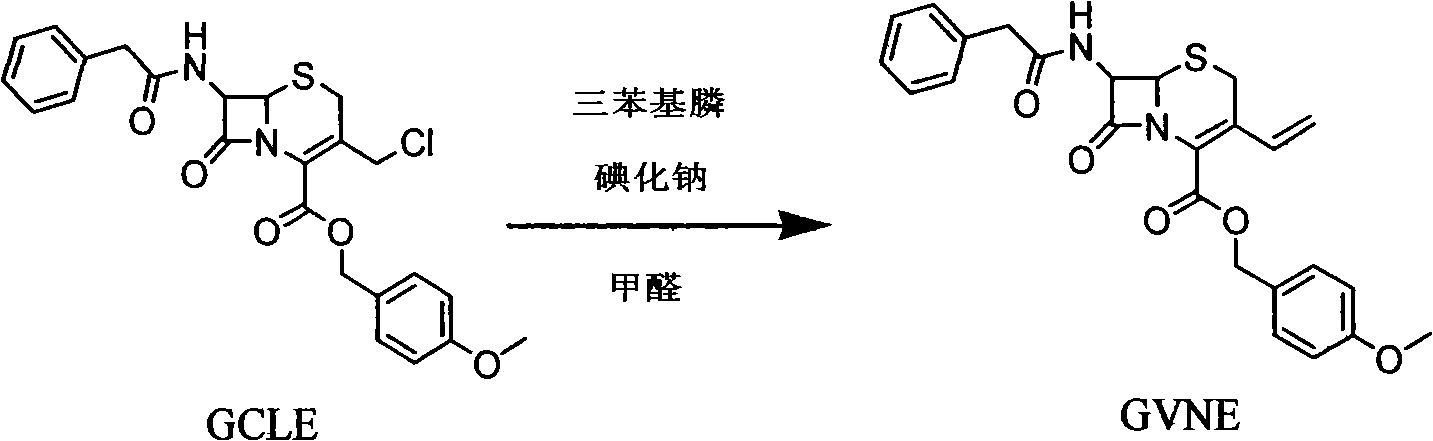

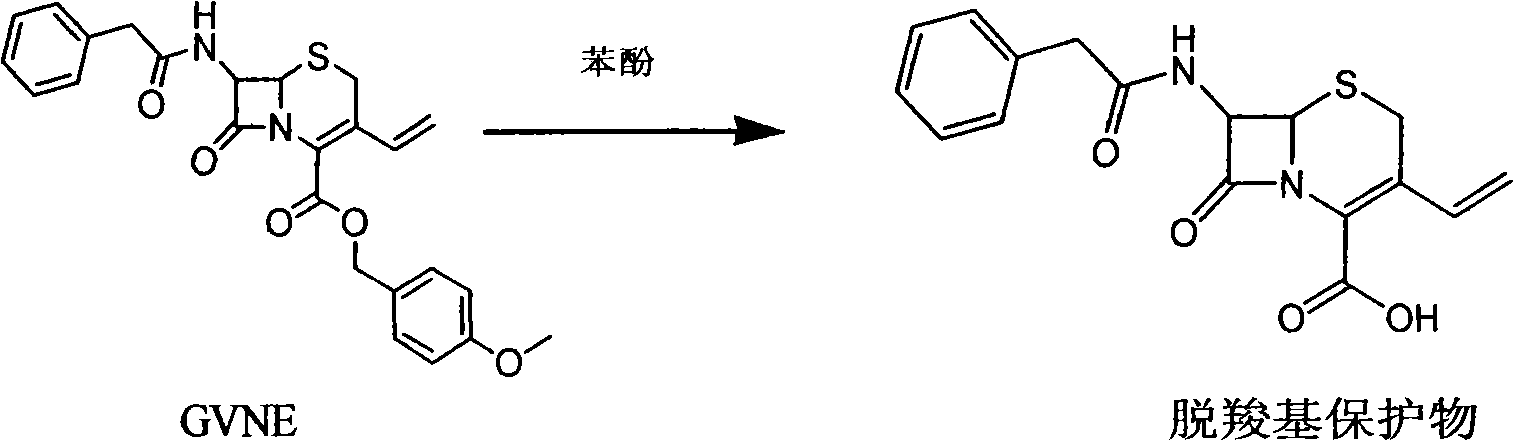

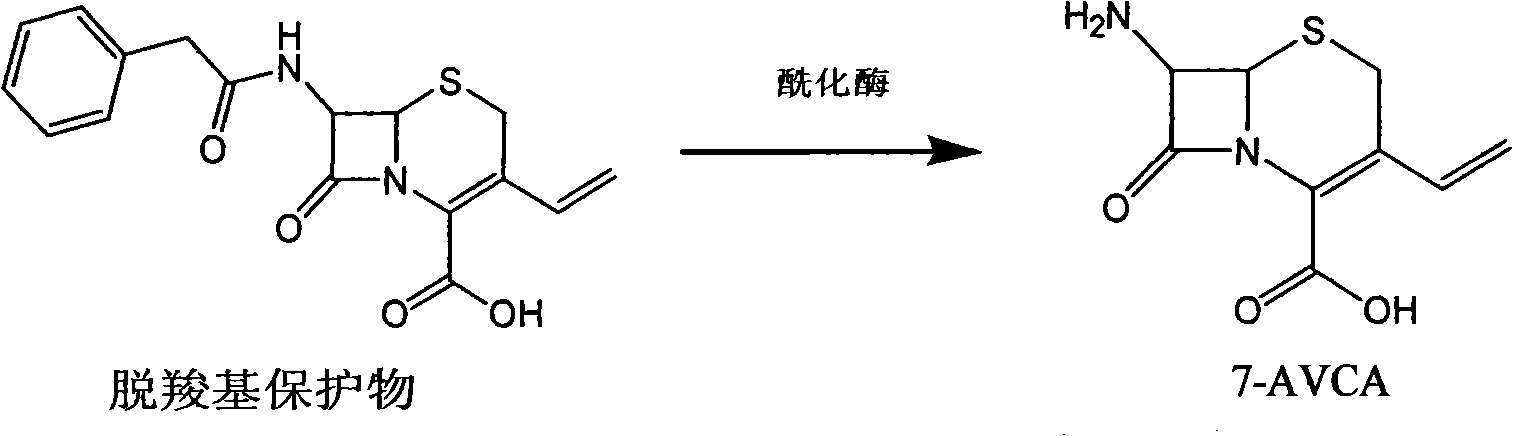

Embodiment 1

[0047] Put DMF / 22.5ml, methylene chloride 83ml into a 500ml three-necked flask, add 4.7g sodium iodide, 8.9g triphenylphosphine, 15g GCLE, heat up to 30°C for 1 hour, cool down to 10°C, add formaldehyde 27 gram, 100ml of 8% liquid caustic soda, react for 10 minutes, adjust the pH value to 4 with hydrochloric acid, add water and dichloromethane to dilute the system, separate the water layer, recover the dichloromethane layer to dryness, add methanol, heat up to 40 degrees to crystallize , After adding water, cool to 3 degrees, and filter to get GVNE. Put 50 grams of phenol into a three-necked flask, raise the temperature to 100 degrees to activate for two hours, then add dry GVNE / 25 grams, react for 10 hours until the GVNE residue is qualified, add butyl acetate and water, separate the water layer, and use butyl acetate again Wash the water layer with ester, add activated carbon to decolorize and filter the water layer after layering, add 25 grams of enzyme to the filtrate, rai...

Embodiment 2

[0049] The preparation method and process are the same as in Example 1, except that ethylene glycol is used to prepare cefixime methyl.

Embodiment 3

[0051] Put DMF / 22.5ml, methylene chloride 83ml into a 500ml three-necked flask, add 4.7g sodium iodide, 8.9g triphenylphosphine, 15g GCLE, heat up to 30°C for 1 hour, cool down to 10°C, add formaldehyde 27 gram, 100ml of 8% liquid caustic soda, react for 10 minutes, adjust the pH value to 4 with hydrochloric acid, add water and dichloromethane to dilute the system, separate the water layer, recover the dichloromethane layer to dryness, add methanol, heat up to 40 degrees to crystallize , After adding water, cool to 3 degrees, and filter to get GVNE. Put 50 grams of phenol into a three-necked flask, raise the temperature to 100 degrees to activate for two hours, then add dry GVNE / 25 grams, react for 10 hours until the GVNE residue is qualified, add butyl acetate and water, separate the water layer, and use butyl acetate again Wash the water layer with ester, add activated carbon to decolorize and filter the water layer after layering, add 25 grams of enzyme to the filtrate, rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com