Ordered mesoporous nanocrystalline titanic oxide/carbon compound material and synthetic method

A carbon composite material, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of large specific surface area, simple equipment requirements and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

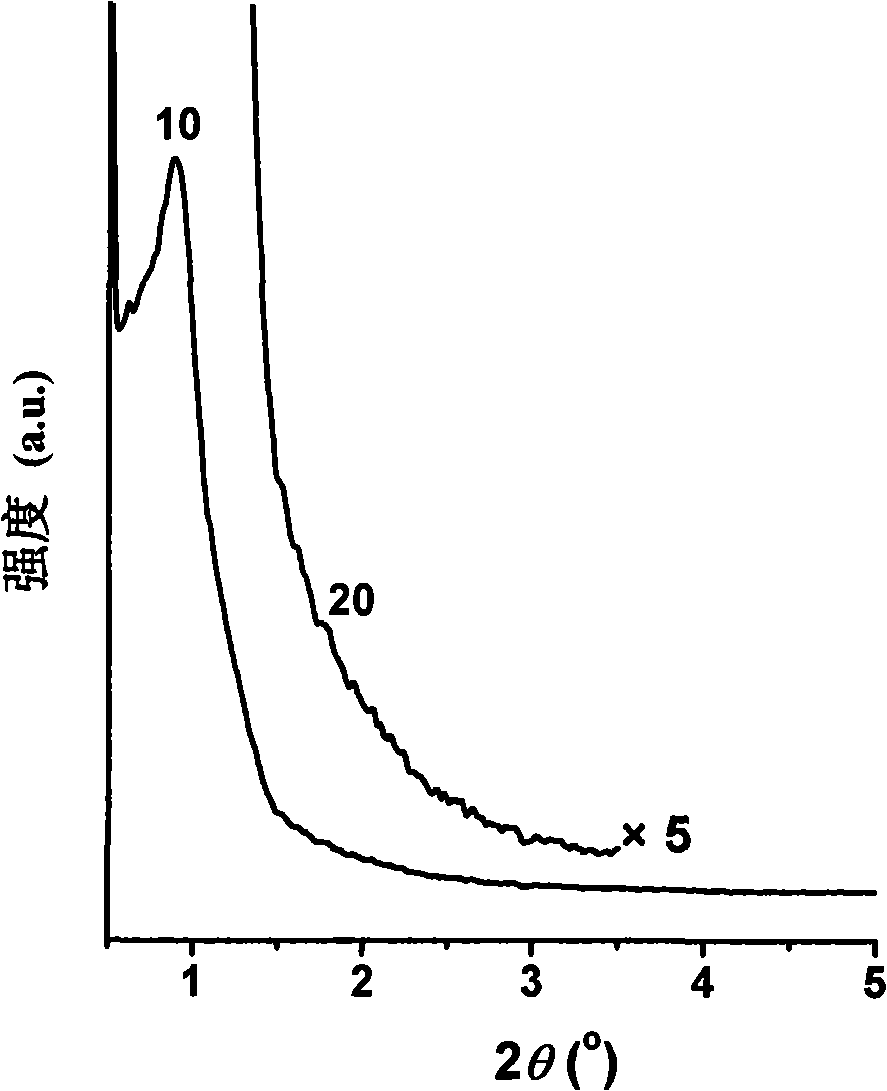

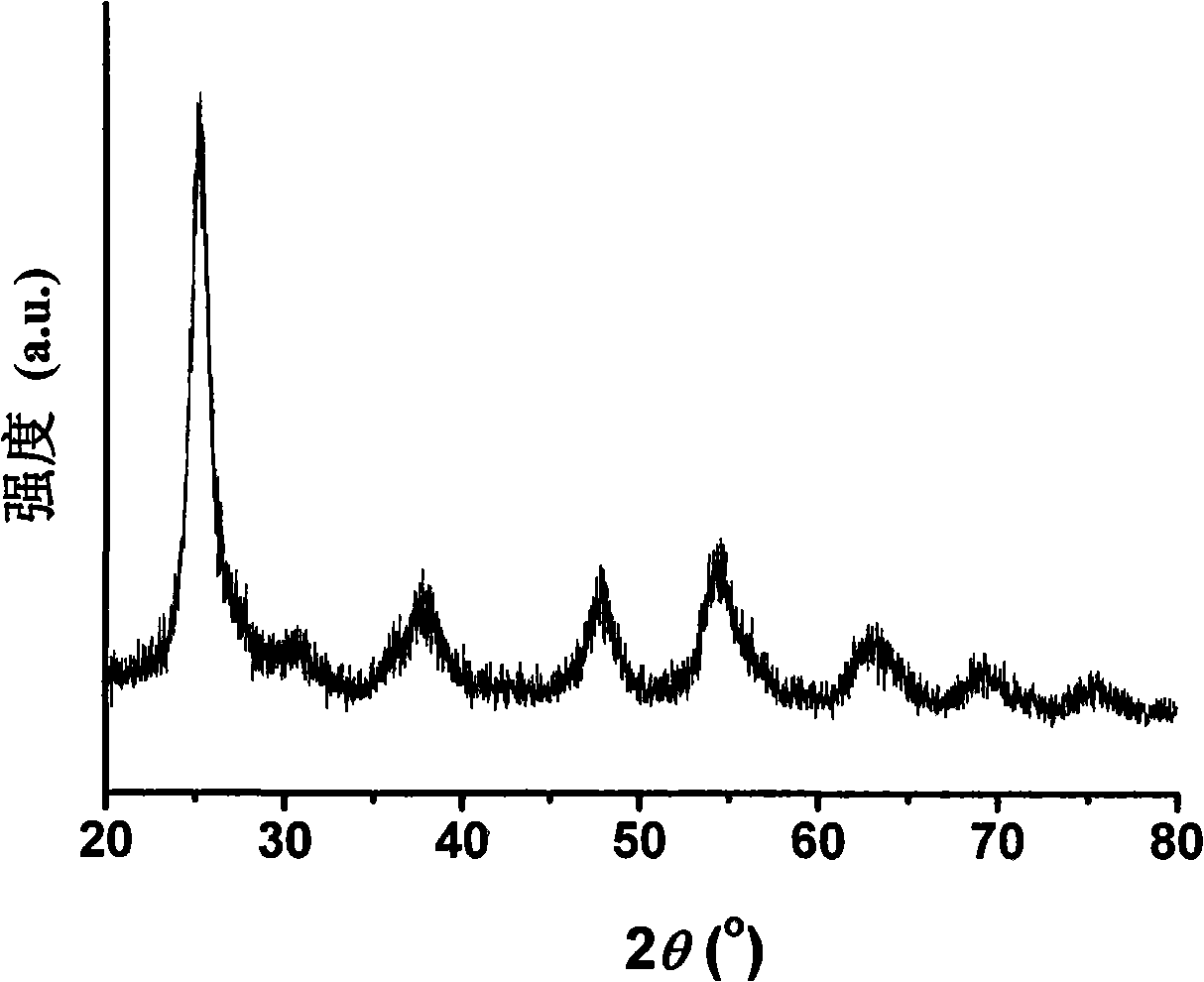

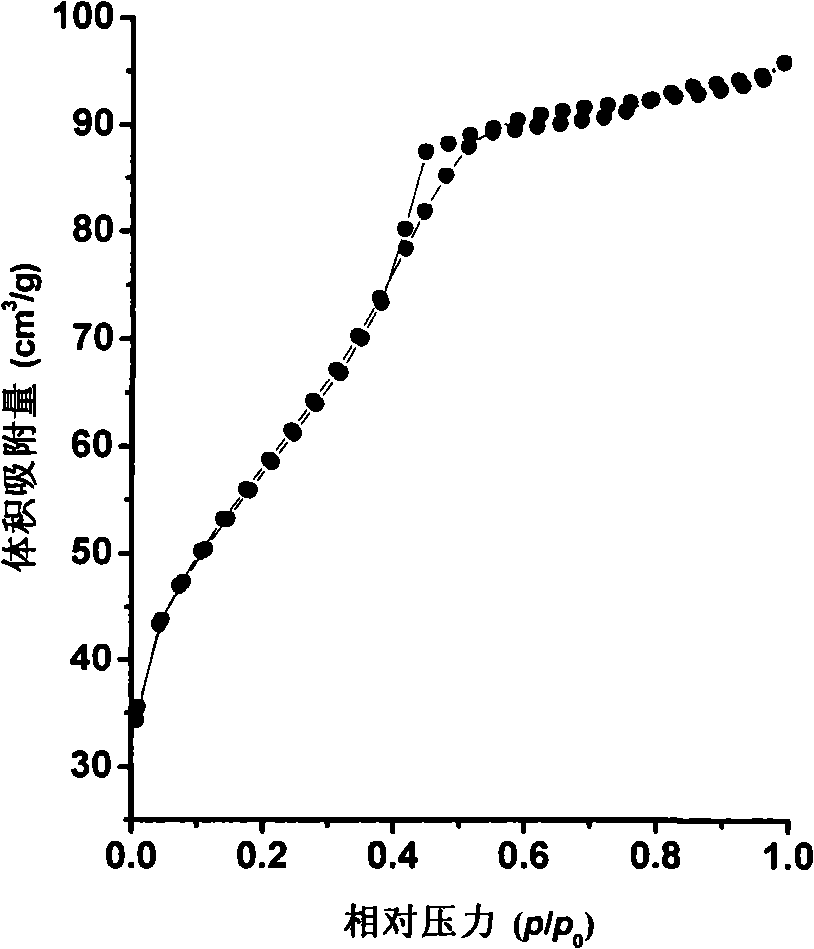

[0036] 0.7g (3.7mmol) TiCl 4 , 2.1g (6.3mmol) Ti(OC 4 h 9 ) 4 And 1.0g (20wt%) resole phenolic resin ethanol solution is added in the transparent solution containing 1.0g P123, 20g ethanol, stirs 1-2h, obtains an orange-red transparent solution. This solution is transferred in the petri dish, room temperature evaporates 1 -2d, then thermally polymerized at 100°C for 24h. The scraped film was roasted at 350°C for 5 hours to remove the surfactant at a heating rate of 1°C / min, and then crystallized at 550°C for 30 minutes at a heating rate of 5°C / min to obtain a mesoporous nanocrystalline titanium dioxide / carbon composite material. The material has a pore diameter of 3.4nm and a pore volume of 0.15cm 3 / g, the specific surface area is 207m 2 / g. The XRD spectrum proves that the obtained mesoporous nanocrystalline titanium dioxide / carbon composite material has high crystallinity anatase, and the pore space symmetry is p6mm. See the small-angle and wide-angle XRD spectrum and...

Embodiment 2

[0038] 0.61g (3.2mmol) TiCl 4 , 2.3g (6.8mmol) Ti(OC 4 h 9 ) 4 Add 2.5g (20wt%) resole phenolic resin ethanol solution containing 1.0g P123, in the transparent solution of 20g ethanol, stir 1-2h, obtain an orange-red transparent solution. This solution is transferred in the petri dish, room temperature evaporates 1 -2d, then thermally polymerized at 100°C for 24h. The scraped film was roasted at 350°C for 5 hours to remove the surfactant at a heating rate of 1°C / min, and then crystallized at 550°C for 30 minutes at a heating rate of 5°C / min to obtain a mesoporous nanocrystalline titanium dioxide / carbon composite material. The material has a pore diameter of 4.4nm and a pore volume of 0.25cm 3 / g, the specific surface area is 274m 2 / g. The XRD spectrum proves that the obtained mesoporous nanocrystalline titanium dioxide / carbon composite material has high crystallinity anatase, and the pore space symmetry is p6mm. Figure 5 , 6 , 7.

Embodiment 3

[0040] 0.7g (3.7mmol) TiCl 4 , 2.1g (6.3mmol) Ti(OC 4 h 9 ) 4 And 1.0g (20wt%) resole phenolic resin ethanol solution is added in the transparent solution containing 1.0g Brij56, 20g ethanol, stirs 1-2h, obtains an orange-red transparent solution. This solution is transferred in the petri dish, room temperature evaporates 1 -2d, then thermally polymerized at 100°C for 24h. The scraped film was roasted at 350°C for 5 hours to remove the surfactant at a heating rate of 1°C / min, and then crystallized at 550°C for 30 minutes at a heating rate of 5°C / min to obtain a mesoporous nanocrystalline titanium dioxide / carbon composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com