Alkaline kation feed immunopotentiator solution, production method and uses thereof

An immune enhancer and alkaline cation technology, applied in animal feed, animal feed, application, etc., can solve problems affecting human food safety, increased animal drug resistance, excessive drug residues, etc., to improve feed conversion efficiency, significantly non-specific Physiological regulation of the opposite sex, the effect of promoting animal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of Immunopotentiator for Alkaline Cationic Feed

[0025] In the embodiment of the present invention, using 0.05m 3 2 seed tanks, 0.1m 3 Fermentation tank 1, 0.3m 3After one fermenter was cleaned and sterilized, the culture medium was prepared according to 80g tryptone, 785g glucose, 6g sodium chloride, 11g aluminum hydroxide gel, 4.5g sodium zincate, 45g oligochitosan, 0.08g Sodium sulfite, 15g of biotite powder, and 1000ml of pure water were dissolved in the proportion of the prepared medium, respectively injected into the above-mentioned fermentation device, sterilized by autoclaving at 121°C for 40 minutes, and cooled to 37°C; Bacillus and lactic acid bacteria strain freeze-dried powder 1 each, after activation on the slant medium, select a single colony to inoculate the primary-secondary seed tank (0.05m 3 The liquid culture medium of 2 seed tanks) is carried out anaerobic culture, and the culture temperature is 37 ℃, when seed liquid OD 450nm =1.3, ...

Embodiment 2

[0027] Preparation of Immunopotentiator for Alkaline Cationic Feed

[0028] In the embodiment of the present invention, using 0.05m 3 2 seed tanks, 0.5m 3 After the three fermenters were cleaned and sterilized, the culture medium was prepared according to 60g tryptone, 21g soybean polypeptide, 680g glucose, 9g sodium chloride, 15g aluminum hydroxide gel, 4.5g sodium zincate, and 30g oligomeric chitosan Sugar, 0.08g of sodium sulfite, 20g of biotite powder, dissolved in 1000ml of pure water to prepare medium, respectively poured into the above-mentioned fermentation device, sterilized by autoclaving at 121°C for 40 minutes, cooled to 37°C; Preserved bifidobacterium and lactic acid bacteria strain freeze-dried powder each 1, after activation on the slant medium, select a single colony to inoculate the primary-secondary seed tank (0.05m 3 The liquid culture medium of 2 seed tanks) is carried out anaerobic culture, and the culture temperature is 37 ℃, when seed liquid OD 450nm ...

Embodiment 3

[0030] Preparation of fermented feed additives

[0031] There are 300Kg of wheat bran, 500Kg of fine rice bran, 150Kg of soybean meal, and 10Kg of biotite powder in every 1000Kg of feed additive raw materials. They are pulverized and mixed uniformly. 3L of the solution prepared in Example 1 is added to 400L of water, and then 5Kg of brown sugar is added. In the pulverized raw materials, mix evenly, ferment at 25°C for 4-6 days, and stir twice a day during this period, and ferment until orange-yellow and when the temperature reaches 50°C and there is a strong taste of distiller's grains, stop the fermentation, and take another 40L of Example 1. The prepared solution is fully mixed with the fermented product, dried and pulverized at 80-120° C., and is a broad-spectrum, multifunctional and powerful alkaline cationic immune-enhancing feed additive.

PUM

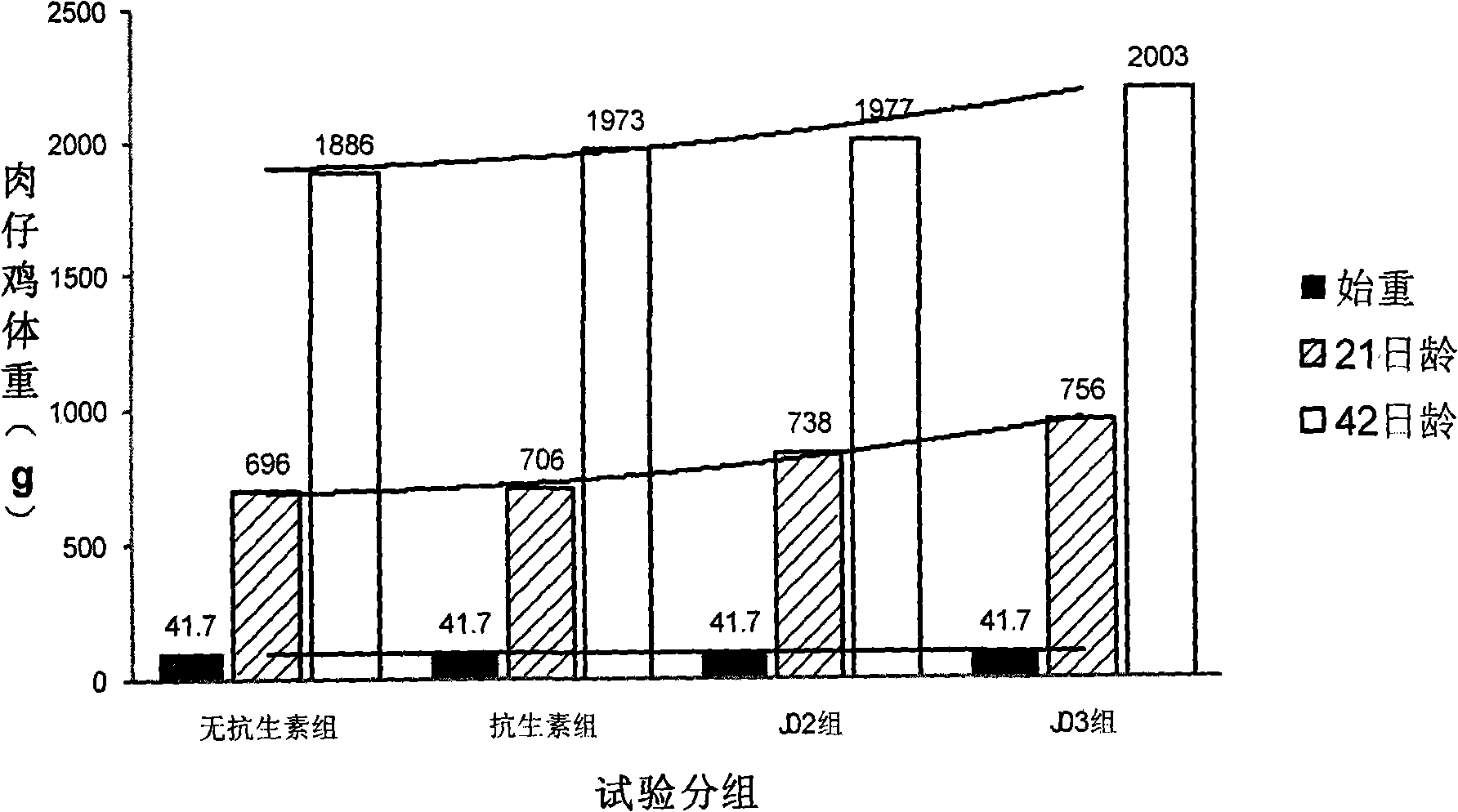

| Property | Measurement | Unit |

|---|---|---|

| Average weight | aaaaa | aaaaa |

| Average weight | aaaaa | aaaaa |

| Average weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com