Chemical industry metallurgical comprehensive approach for nepheline ore by completely-wet method

A technology for chemical metallurgy and comprehensive treatment, applied in the field of chemical metallurgy, can solve the problems of low aluminum output rate, no substantial test and industrial development, poor comprehensive utilization, etc., and achieve the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

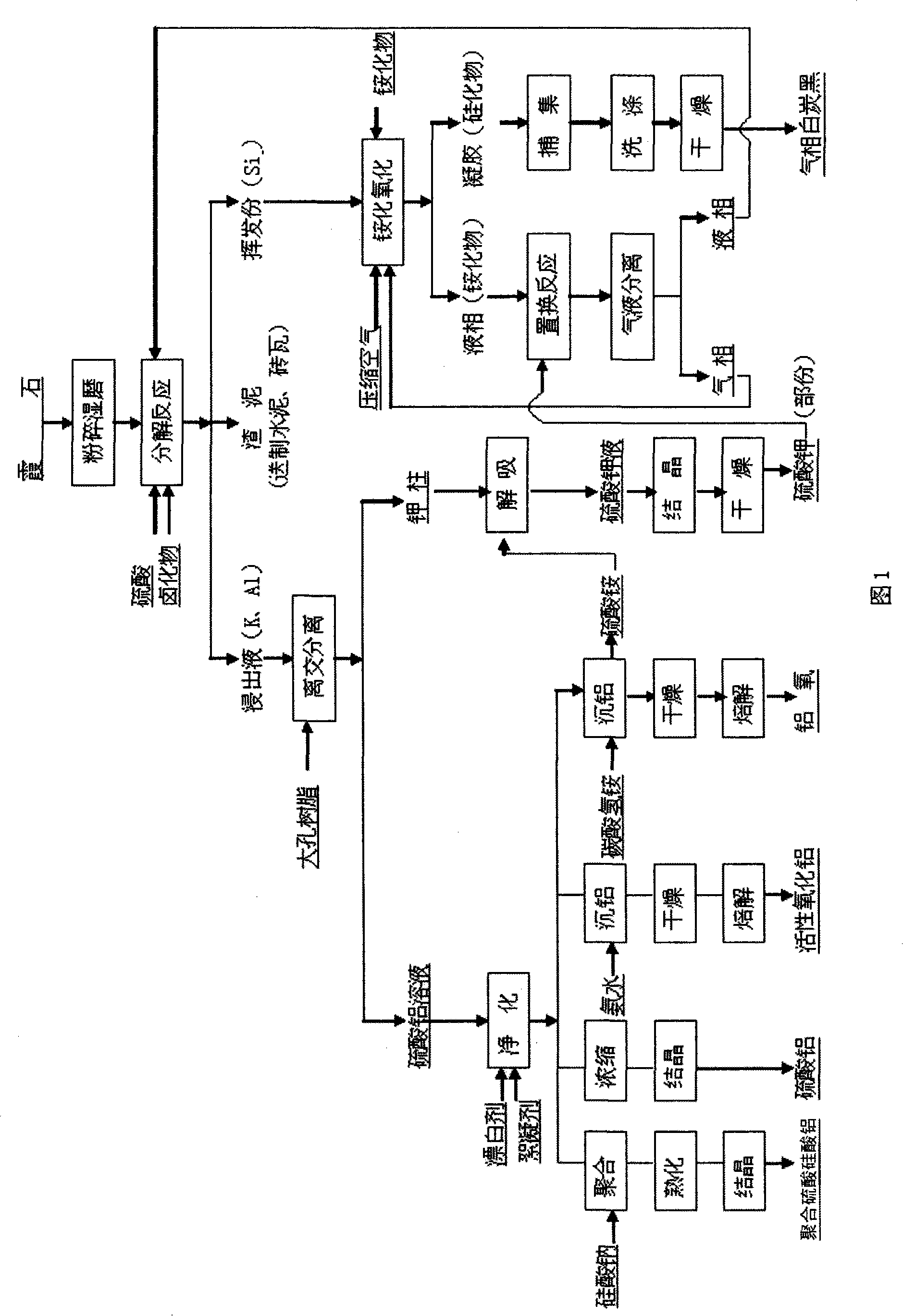

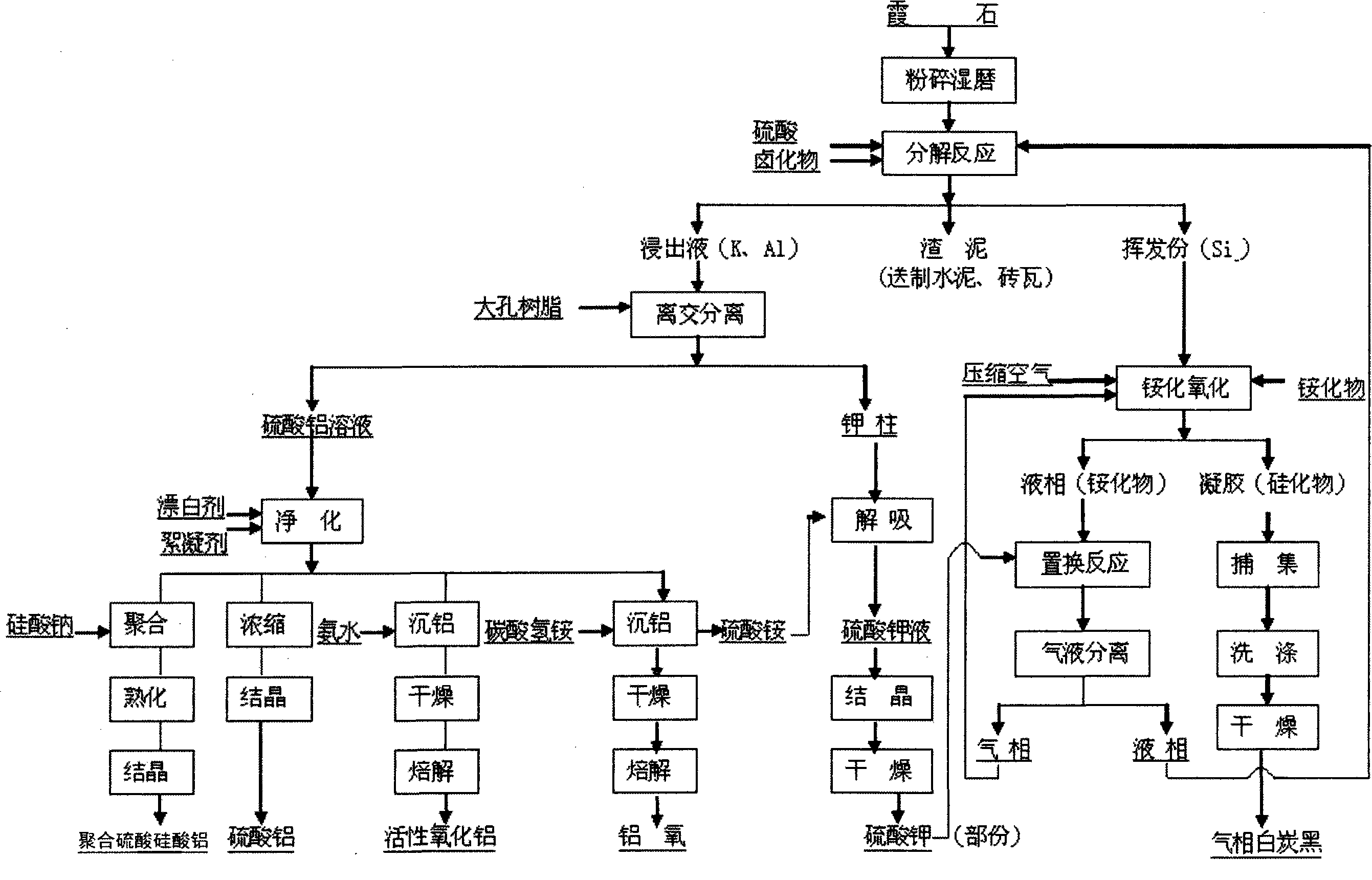

Method used

Image

Examples

example 1

[0037] Example 1: Alumina, potassium sulfate and fumed silica produced from Gejiu nepheline

[0038] 1. Main ingredients of raw materials:

[0039] Al 2 o 3 26.36%, K 2 O 10.88%, SiO 2 51.32%

[0040] Second, the main process:

[0041] Mineral crushing and wet grinding, activation and decomposition of sulfuric acid; gas-phase ammonium oxidation, capture, washing, and drying to obtain gas-phase white carbon black; solid-liquid separation of reactants, slag sent to cement or bricks; liquid-phase ion exchange for hanging potassium; separation The solution after potassium is purified and removed, and the pH is adjusted with ammonium bicarbonate to precipitate aluminum, and the obtained aluminum hydroxide is washed, dried, and roasted to obtain aluminum oxide; the ammonium sulfate solution after aluminum precipitation is used to desorb potassium column to obtain potassium sulfate solution , Potassium sulfate was obtained by concentration and crystallization.

[0042] Three...

example 2

[0077] Example 2: Activated alumina, potassium sulfate and fumed silica made from Gejiu nepheline

[0078] 1. The main components of raw ore:

[0079] Al 2 o 3 27.88%, K 2 O 10.21%, SiO 2 50.13%

[0080] Second, the main process:

[0081] Mineral crushing and wet grinding, activation and decomposition of sulfuric acid; gas-phase ammonium oxidation, capture, washing, and drying to obtain gas-phase white carbon black; solid-liquid separation of reactants, slag sent to cement or bricks; liquid-phase ion exchange for hanging potassium; separation After the potassium solution is purified, the pH is adjusted with ammonia water under strong stirring to precipitate aluminum, and the loose aluminum hydroxide is washed, beaten, spray-dried and roasted to obtain fine chemical product activated alumina; the precipitated ammonium sulfate solution is used for desorption Potassium column to obtain potassium sulfate solution, concentrated and crystallized to obtain potassium sulfate. ...

example 3

[0113] Example 3: PASS, potassium carbonate and fumed silica made from Gejiu nepheline

[0114] 1. The main components of raw ore:

[0115] Al 2 o 3 28.42%, K 2 O 9.83%, SiO 2 49.86%

[0116] Second, the main process:

[0117] Mineral crushing and wet grinding, activation and decomposition of sulfuric acid; gas-phase ammonium oxidation, capture, washing, and drying to obtain gas-phase white carbon black; solid-liquid separation of reactants, slag sent to cement or bricks; liquid-phase ion exchange for hanging potassium; separation After the potassium solution is purified, under high-speed stirring, the pre-polysilicate sodium is slowly added to it according to the modulus ratio of aluminum to silicon is 1:1, high-speed stirring at constant temperature, polymerization, digestion, aging, concentration, crystallization, and dehydration. Get PASS; desorb potassium column with ammonium bicarbonate to obtain potassium carbonate solution, and concentrate to 40% (by K 2 CO 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com