Process for preparing hydrogen gas and nanometer carbon by catalyzing and cracking methane at low temperature

A low-temperature catalysis, nano-carbon technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of unreachable methane conversion rate, decreased specific surface area, and inability to carry out the process, and achieves improved operational safety and production. Cost and operation and maintenance reduction, the effect of increasing the operating life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing hydrogen and nano-carbon by catalytic cracking methane at a low temperature, the method comprising the following steps:

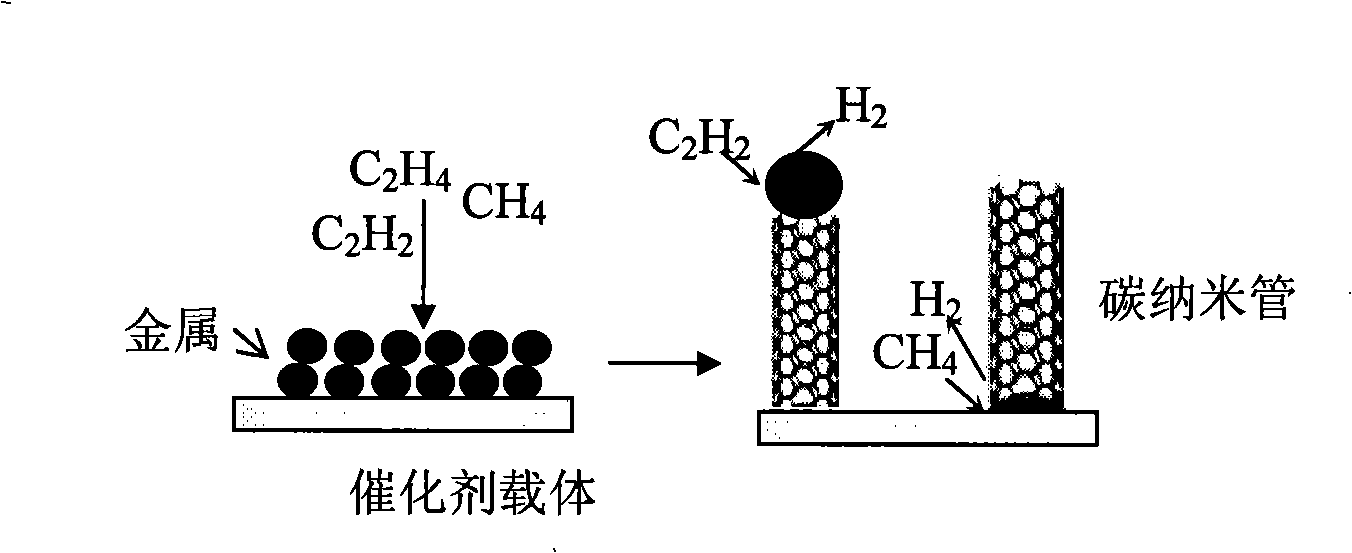

[0033] (1) Use nano-metal catalysts containing iron, molybdenum, and aluminum to control the average grain size of the nano-metals to 10nm and the specific surface area to be 300m 2 / g, the bulk density is 400kg / m 3 , the Mohs hardness is 6.8, the particle size range is 20-150 microns, and the average particle size is 75 microns. Put it into a fluidized bed reactor, heat up to 500°C, and reduce the catalyst with high-purity nitrogen containing 5% hydrogen for about 3 hours; then heat up to 650°C; (2) feed 51% methane, 49% acetylene Mixed gas, the control catalyst space velocity is 250 liters of hydrocarbons / gram catalyst / h, and operating pressure is 0.15MPa (absolute pressure) to react, with figure 1 The model shown generates hydrogen gas with nanocarbon products. Within 2 hours, the conversion rate of acetylene is 100%, the...

Embodiment 2

[0035]A method for preparing hydrogen and nano-carbon by catalytic cracking methane at a low temperature, the method comprises the following steps: (1) using a nano-metal catalyst containing nickel and copper supported on aluminum oxide, controlling the average grain size of the nano-metal to 50nm, the specific surface area is 200m 2 / g, the bulk density is 650kg / m 3 , the Mohs hardness is 7.3, the particle size range is 30-250 microns, and the average particle size is 175 microns. Put it into a fluidized bed reactor, raise the temperature to 400°C, reduce the catalyst with high-purity nitrogen containing 50% hydrogen for about 7 hours, and then raise the temperature to 450°C; (2) feed 81% methane, 19% ethylene Mixed gas, the catalyst space velocity is controlled to be 450 liters of hydrocarbons / g catalyst / h, and the operating pressure is 0.13 MPa (absolute pressure) for reaction. by figure 1 The model shown generates hydrogen gas with nanocarbon products. The conversion r...

Embodiment 3

[0037] A method for preparing hydrogen and nano-carbon by catalytic cracking methane at a low temperature, the method comprises the following steps: (1) loading iron and chromium nano-metal on the oxidized and truncated figure 1 On the carbon product in the catalyst, it constitutes a catalyst. Control the grain size of its nanometer metal to be 10nm on average, and the specific surface area is 350m 2 / g, the bulk density is 450kg / m 3 , the Mohs hardness is 6.3, the particle size range is 30-200 microns, and the average particle size is 105 microns. Put it into a fluidized bed reactor, raise the temperature to 500°C, reduce the catalyst with high-purity nitrogen containing 15% hydrogen for about 0.5 hours, and then raise the temperature to 650°C; (2) feed 25% methane, 75% propylene Mixed gas, the control catalyst space velocity is 150 liters of hydrocarbons / gram catalyst / h, and operating pressure is 0.11MPa (absolute pressure) to react, with figure 1 The model shown generate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com