Method for preparing of low stress chromium nitride multilayer hard film

A chromium nitride, low-stress technology, applied in the field of preparation of low-stress chromium nitride multilayer hard film, can solve the problems of Cr/CrN film hardness limitation, stress reduction, etc., and achieve smooth surface, low internal stress, and defects little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A specific embodiment of the present invention is that a method for preparing a low-stress chromium nitride multilayer hard film is carried out by using an unbalanced magnetron sputtering device, and the specific method is:

[0022] A. Cleaning Put the workpiece cleaned by acetone and absolute ethanol in a vacuum chamber, use more than 99.99% pure chromium as the target, close the vacuum chamber, and evacuate to 3.0×10 -3 When Pa, argon gas is introduced to make the pressure in the vacuum chamber reach 1~2Pa, turn on the bias power supply, apply -1500V bias voltage to the workpiece, glow discharge to form argon plasma, and clean the workpiece by argon plasma sputtering 10 minutes; turn on the power of the target, apply a current of 3A to pre-sputter cleaning the target for 5 minutes to remove impurities such as oxides and nitrides on the surface of the target.

[0023] B. Chromium transition layer deposition After cleaning is completed, adjust the argon pressure to 10 -1 ~1...

Embodiment 2~12

[0027] Embodiments 2-12 are basically the same as Embodiment 1, except that during the C-step chromium nitride film deposition process, the workpiece bias voltage amplitude is set differently, the deposition time is different, the deposition thickness is different, and the number of repetitions is different. The specific values are shown in the following table (in order to better represent the different process conditions of each embodiment, the relevant parameters of Example 1 are also listed in the following table, and the number of repetitions in the table includes the first time):

[0028] The process parameters of Examples 1-12 and the thickness of the deposited chromium nitride multilayer hard film

[0029]

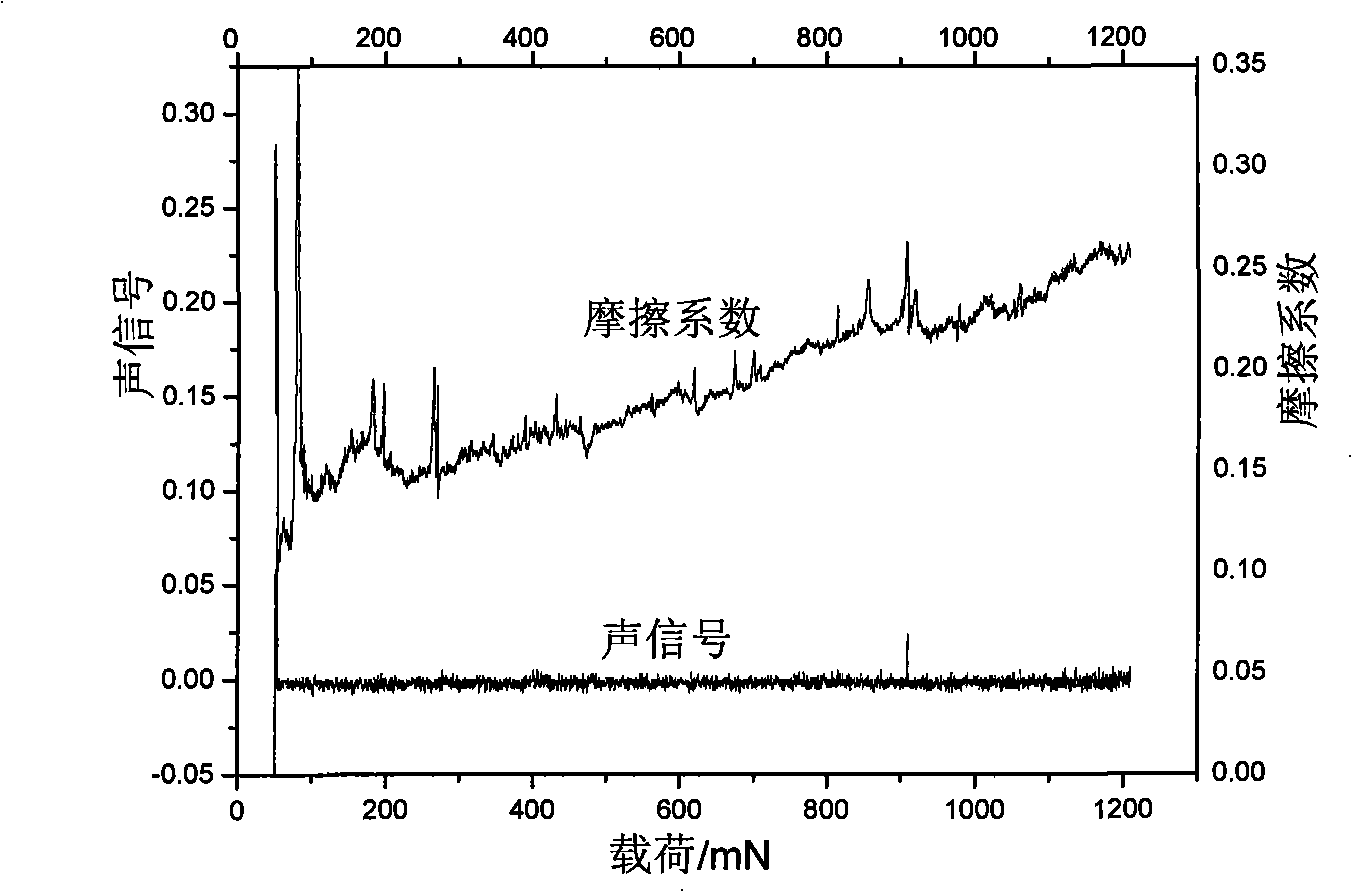

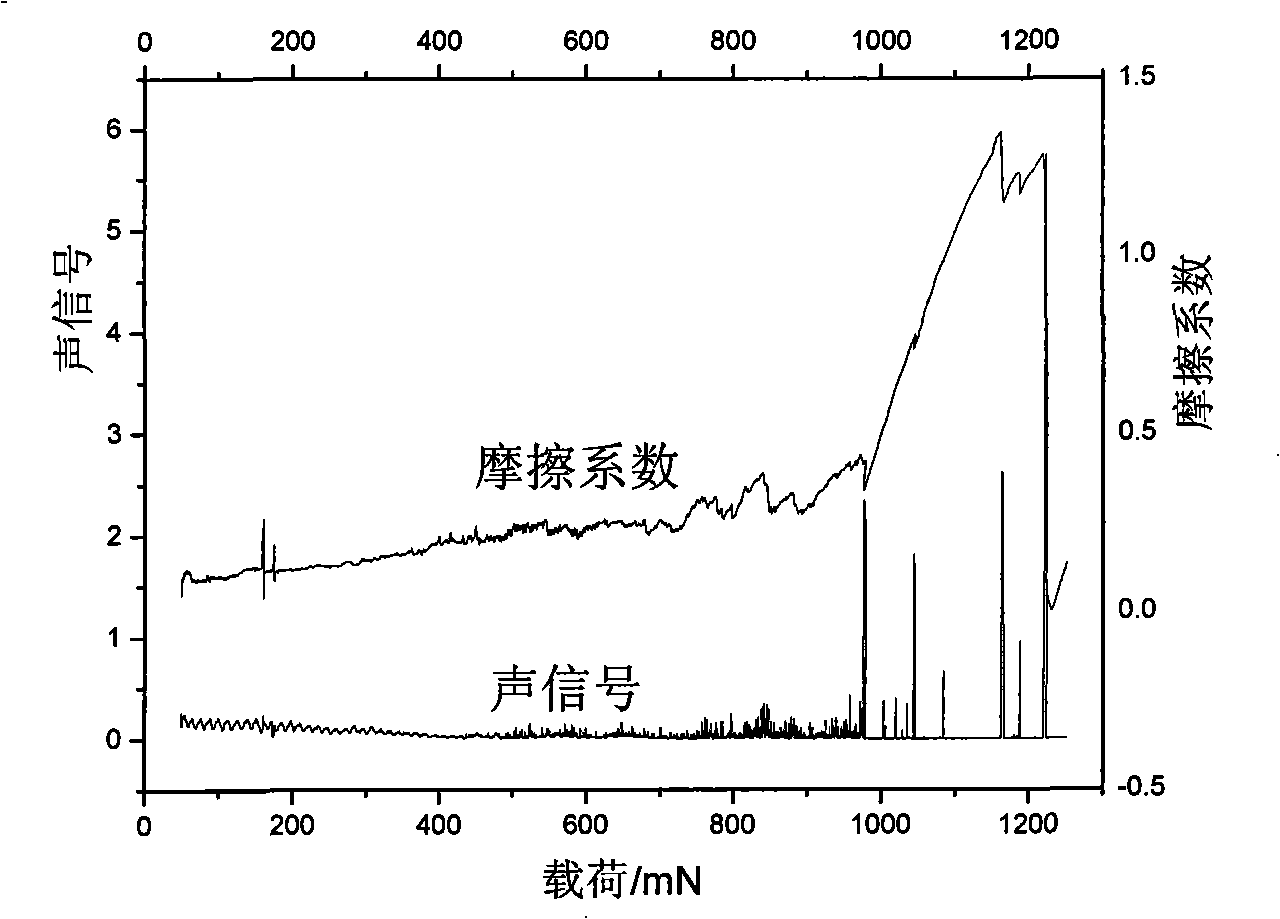

[0030] Figure 1a This is the test result of the bonding force of the low-stress chromium nitride hard film prepared by the method of Example 1 of the present invention. In the scratch test, when the load was increased to 1200mN, the friction coefficient and acoust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com