Surface plasma resonance image-forming nanostructure array chip preparation method

A surface plasmon and nanostructure technology, which is applied in phase influence characteristic measurement, scattering characteristic measurement, instrument and other directions, can solve the problems such as blurring of sample point edge, and achieve the effect of good uniformity and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

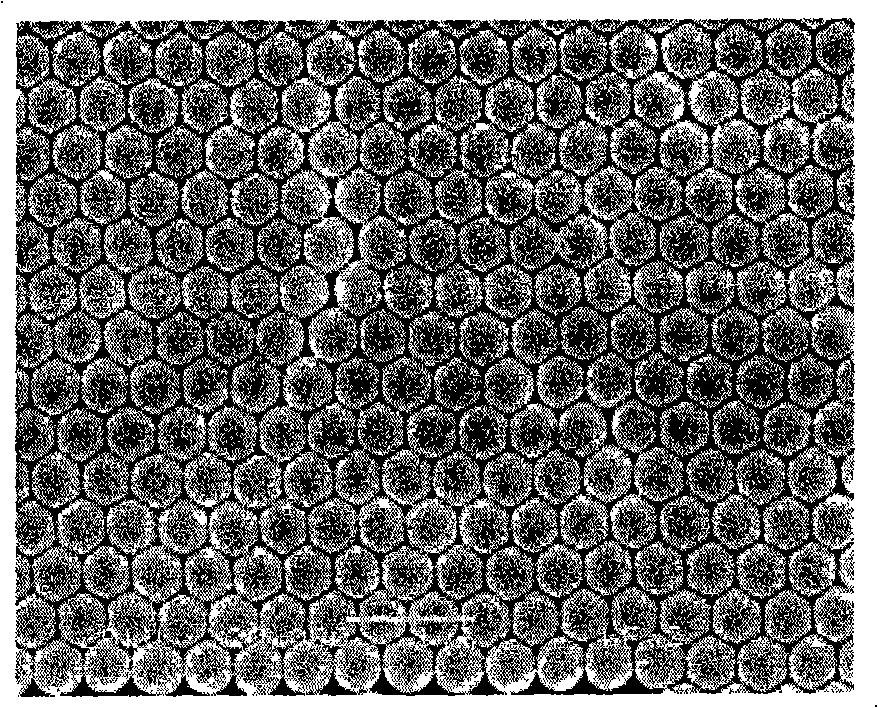

[0035] Example 1, a surface plasmon resonance imaging nanostructure array chip with a lattice density of 625 dots / square centimeter and a nanostructure feature size of less than 70 nanometers manufactured by the method of the present invention.

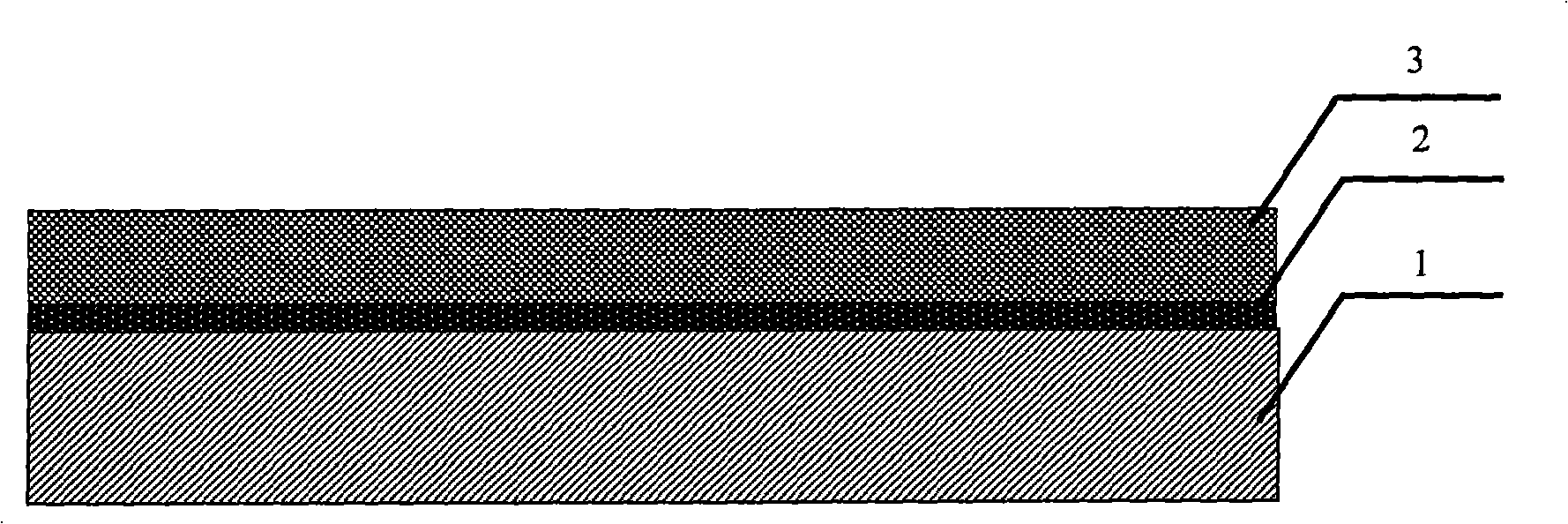

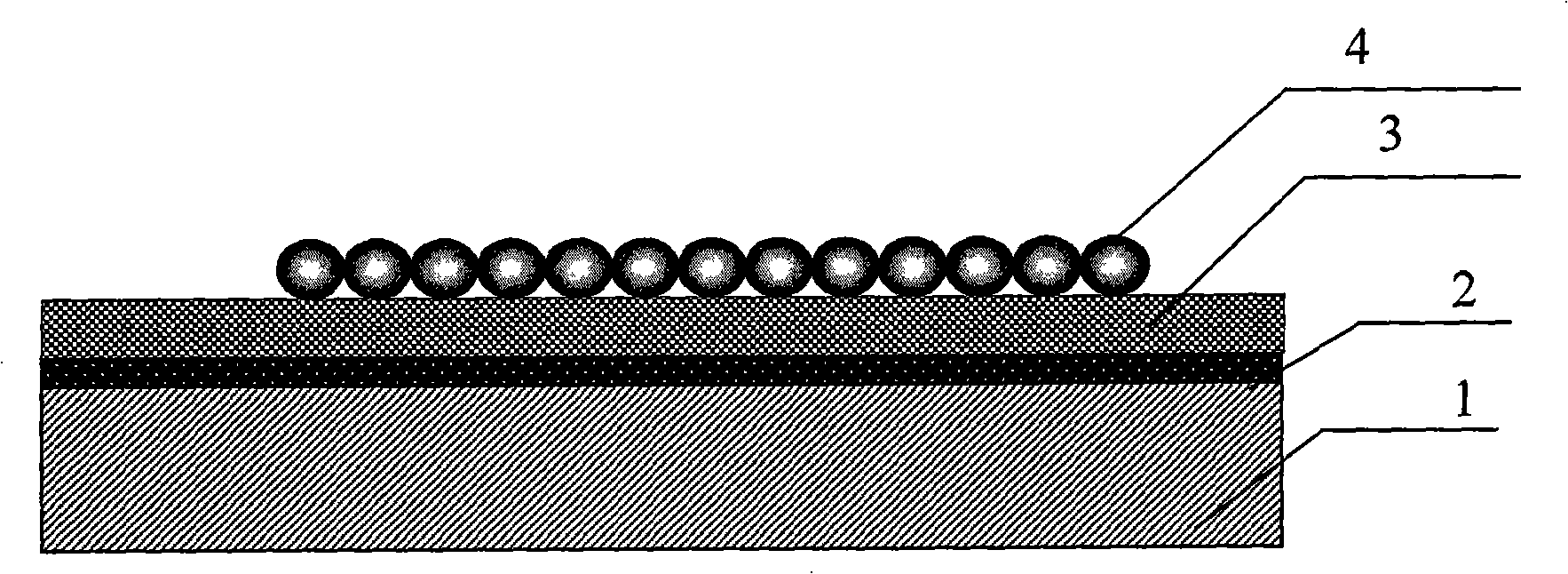

[0036] (1) The glass substrate 1 with a size of 10mm×10mm was warmed at 70°C for 20min in newly prepared Piranha solution (3:1 sulfuric acid:30% hydrogen peroxide) before use to remove surface impurities, and then deionized Rinse with water; put it into the working chamber of the vacuum coating system after drying at low temperature; in order to increase the firmness of the metal film, first vertically evaporate a layer of chromium layer 2 on the surface of the substrate by resistance evaporation under high vacuum, with a thickness of 2nm, and then The first layer of metal thin film 3 is vapor-deposited again, and the metal material is selected metal gold (gold purity 99.99%), and the film thickness is 40nm, and the obtained structure ...

Embodiment 2

[0044] Example 2 is a surface plasmon resonance imaging nanostructure array chip made of silver with a lattice density of 2500 dots / square centimeter, a nanostructure feature size of less than 90 nanometers, and a material made by the method of the present invention.

[0045] (1) The glass substrate 1 with a size of 10mm×10mm was warmed at 70°C for 20min in newly prepared Piranha solution (3:1 sulfuric acid:30% hydrogen peroxide) before use to remove surface impurities, and then deionized water flushing;

[0046] (2) Design the dot matrix graphics, determine the size, shape, and spacing of the dot matrix; the size of the circular dot matrix designed in this example is 0.1mm in diameter and 0.2mm in spacing, and the dot matrix part is transparent, and the rest is opaque For the part, the graphic is made on the mask board by laser direct writing equipment for standby;

[0047] (3) Spin-coat a layer of positive photoresist with a thickness of 1 μm on the surface of the glass sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com