Lipase gel particle and preparation thereof

A gel particle, lipase technology, applied in the direction of enzyme stabilization, etc., can solve the problems of limited effect of stability improvement, complex genetic engineering methods, unable to solve the problem of cheap production, etc., achieve controllable particle size scale, improve activity and stability High performance, easy to industrially implement the effect of magnification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

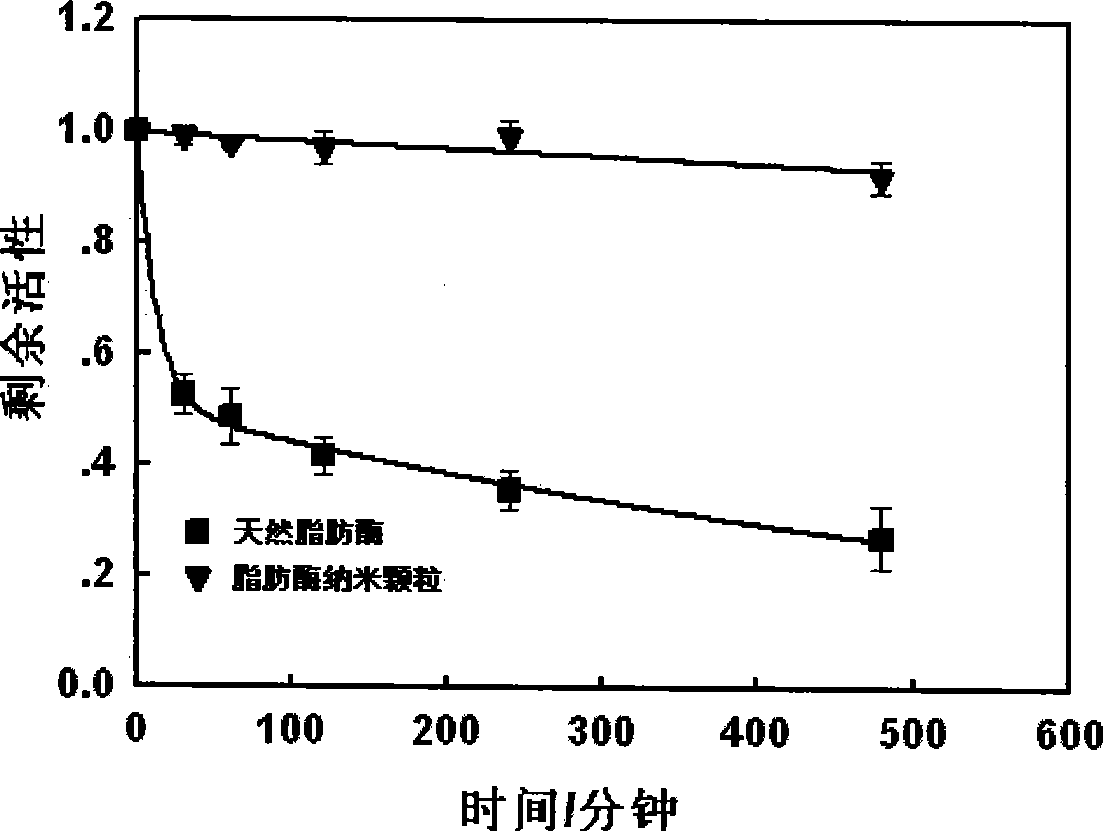

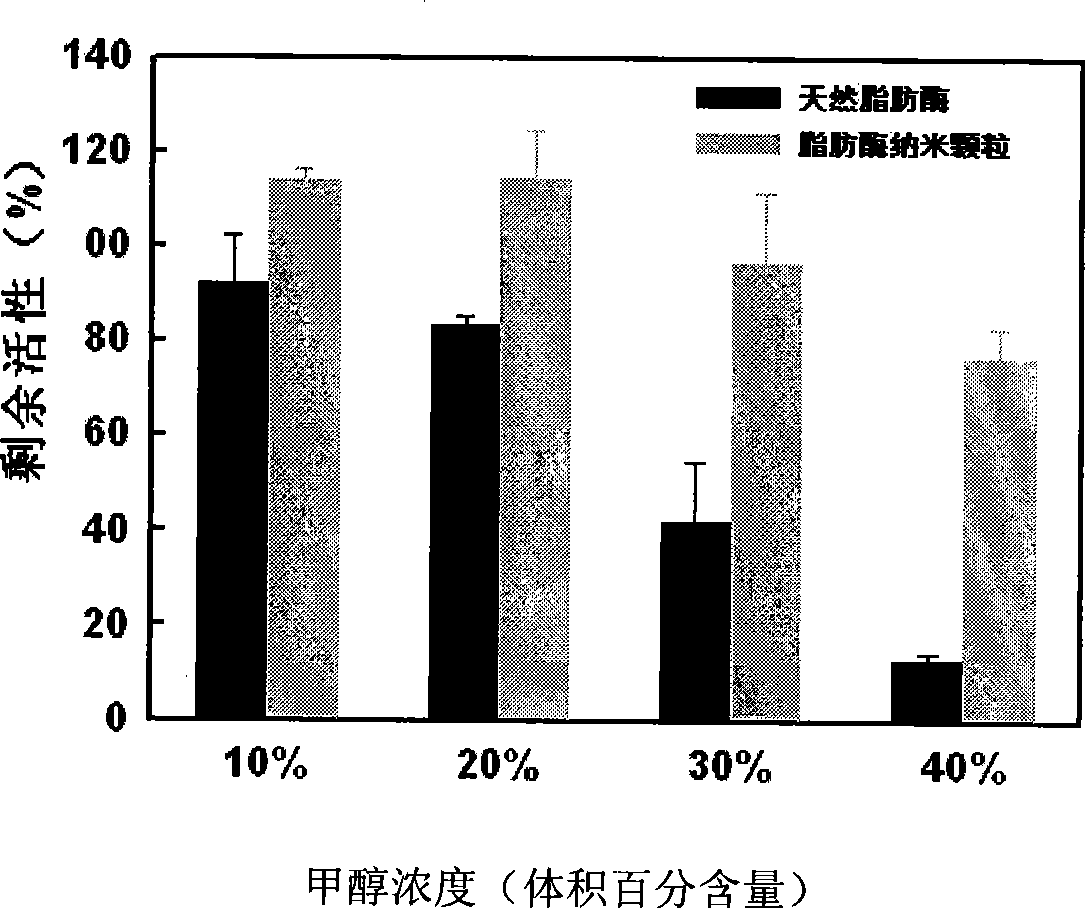

[0024] Embodiment 1, preparation, activity detection and stability detection of lipase gel particles

[0025] 1. Preparation of lipase gel particles

[0026] 1) Add 10 g of lipase (purchased from Sigma, U.S., Candida rugosa lipase) and 2 g of succinimide acrylate (enzyme modifier, purchased from Sigma, U.S.) to 200 mL of 100 mM In acetic acid buffer solution (24.5 mg sodium acetate trihydrate and 49 mg acetic acid dissolved in 200 mL water), react at 20 °C for 6 hours, put the reaction solution into a dialysis bag with a molecular weight cut-off of 10,000, and dialyze in water for 24 hours. Change the water every 6 hours to remove succinimide acrylate;

[0027] 2) Add the reaction solution of the above step 1) to remove the succinimide acrylate ester into 200mL of 2% (mass percentage) dimethyl sulfoxide in an organic solvent aqueous solution, and then add 20g of acrylamide to the reaction solution (vinyl monomer), and an initiator composed of 4g ammonium persulfate and 6g N,...

Embodiment 2

[0036] Embodiment 2, preparation, activity detection and stability detection of lipase gel particles

[0037] 1. Preparation of lipase gel particles

[0038] 1) Add 10 g of lipase (purchased from Sigma, U.S., Aspergillus niger lipase) and 40 g of succinimide acrylate (enzyme modifier, purchased from Sigma, U.S.) to 200 mL of 100 mM acetic acid buffer with a pH of 9.4 (127.5mg of sodium acetate trihydrate and 3.6mg of acetic acid dissolved in 200mL of water) were reacted at 30°C for 4 hours, the reaction solution was put into a dialysis bag with a molecular weight cut-off of 10,000, and dialyzed in water for 24 hours. Change the water every hour to remove succinimide acrylate;

[0039] 2) Add the reaction solution of removing the succinimide acrylate ester in the above step 1) to 200mL of 5% (mass percentage) dimethyl sulfoxide in an organic solvent aqueous solution, and then add 200g of acrylamide ( Vinyl monomer), and an initiator composed of 4g ammonium persulfate and 6g N...

Embodiment 3

[0048] Example 3, preparation, activity detection and stability detection of lipase gel particles

[0049] 1. Preparation of lipase gel particles

[0050] 1) Add 10 g of lipase (purchased from Sigma, U.S., Aspergillus oryzae lipase) and 2 g of succinimide acrylate (enzyme modifier, purchased from Sigma, U.S.) to 200 mL of 100 mM acetic acid buffer at pH 4 (24.5mg of sodium acetate trihydrate and 49mg of acetic acid dissolved in 200mL of water), reacted at 30°C for 5 hours, put the reaction solution into a dialysis bag with a molecular weight cut-off of 10,000, and dialyzed in water for 24 hours, every 6 hours Change the water once to remove succinimide acrylate;

[0051] 2) The reaction solution of the above step 1) for removing succinimide acrylate ester is added to 200mL of 2% (mass percentage) dimethyl sulfoxide in an aqueous organic solvent solution, and then 20g of propylene is added to the reaction solution. Vinyl monomer composed of amide and 0.2g N,N'-methylene bisac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com