Anti-icing nano composite paint and application

A nano-composite, anti-icing technology, applied in coatings, conductors, electrical components, etc., can solve the problems of no obvious anti-icing performance, not given, etc., to speed up the ice melting time, prevent icing, and improve the anti-icing performance. water-based effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A kind of anti-icing nanocomposite coating formula:

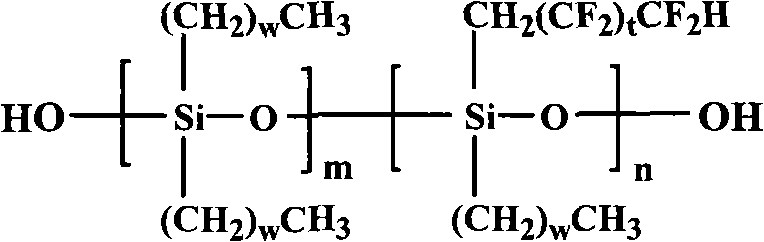

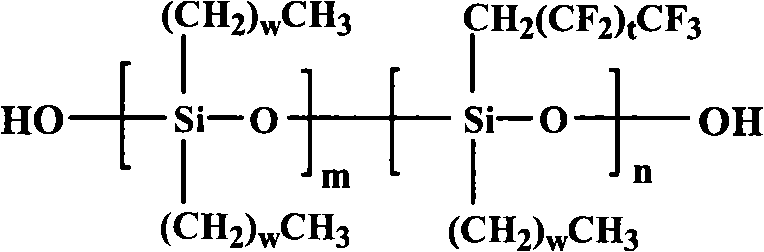

[0080] Organofluorosilicon composite polymer material with a molecular weight of 50,000 g / mol

[0081] 100 kg

[0082] Nano silica 20kg

[0083] Chloroform 100 kg

[0084] Iron dioxide 15 kg

[0085] Ethyl cellulose 5 kg

[0086] Carbon nanotubes 5 kg

[0087] melamine 10kg

[0088] Trimethoxymethylsilane 10kg

[0089] Zinc naphthenate 5kg

[0090] Except for trimethoxymethylsilane, add the rest of the above materials and their amounts into the container and mix them evenly, then slowly add them to the rollers of the three-roller grinder for grinding. After the rubber is even and fine, add trimethoxy base methyl silane, stirring and mixing to obtain the anti-icing nanocomposite coating. The prepared anti-icing nanocomposite coatings are applied to electric power or on communication facilities.

Embodiment 2

[0092] A kind of anti-icing nanocomposite coating formula:

[0093] Organofluorosilicon composite polymer material with a molecular weight of 10 6 g / mol

[0094] 100 kg

[0095] Nano Titanium Dioxide 15kg

[0096] 200 # Solvent oil 150 kg

[0097] Aluminum hydroxide 15 kg

[0099] Ammonium polyphosphate 10 kg

[0100] 107 solidified water 20 kg

[0101] 5 kg of methyl silicone oil

[0102] Tetramethylthiuram disulfide 8kg

[0103] Except for 107 solidified water, first put the rest of the above materials and their amounts into the container and stir on a high-speed mixer, then add 107 solidified water according to the amount, stir and mix well, and then the anti-icing nanocomposite coating is obtained. The prepared anti-icing nanocomposite coatings are applied to electric power or on communication facilities.

Embodiment 3

[0105] A kind of anti-icing nanocomposite coating formula:

[0106] Organofluorosilicon composite polymer material with a molecular weight of 10 7 g / mol

[0107] 100 kg

[0109] Xylene 200 kg

[0110] Carbon black 25kg

[0111] Ethoxylated polytrisiloxane 10 kg

[0112] Montmorillonite 20kg

[0113] Pentaerythritol bromide 10 kg

[0114] Aminotrimethoxysilane 25kg

[0115] Sodium Benzoate 10kg

[0116] Polyvinyl alcohol 10 kg

[0117] Except for aminotrimethoxysilane, first put the rest of the above materials and amounts into the container, stir and mix, grind on a ball mill, after the rubber is uniform and fine, then add dealcoholized aminoalkoxysilane The coupling agent is stirred and mixed evenly to obtain the anti-icing nanocomposite coating. The prepared anti-icing nanocomposite coatings are applied to electric power or on communication facilities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com