Cleaning treatment method and apparatus for malodorous gas

A technology for purification and treatment of malodorous gases, applied in the direction of gasification substances, deodorization, irradiation, etc., can solve the problems of low treatment effect, large investment, and small application range, and achieve the effect of improving treatment efficiency and treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

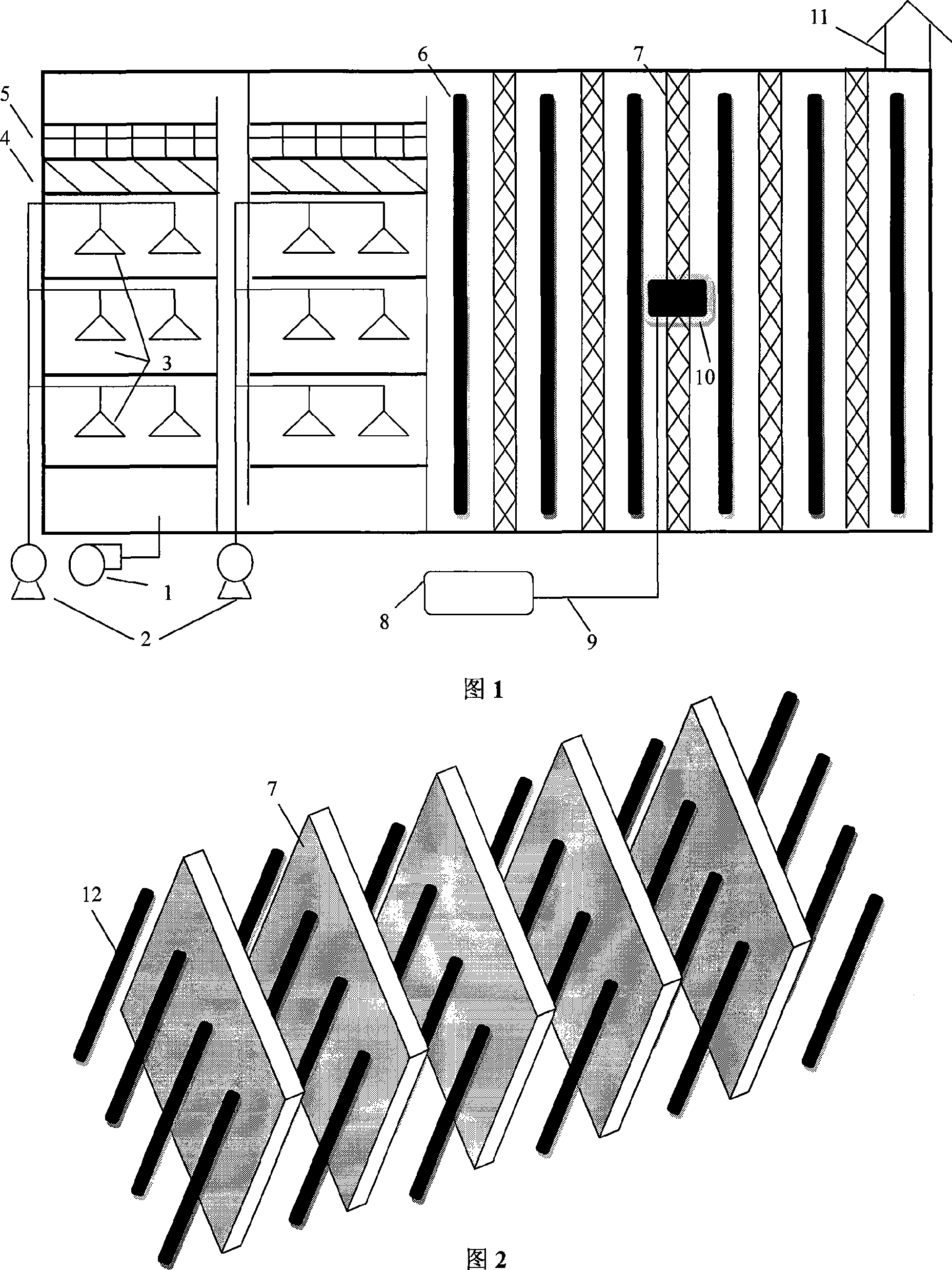

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Utilize the process and device of the present invention to process the malodorous pollutants discharged from a refinery

[0036] Odor pollutants discharged from a refinery include: sulfur, amines, hydrocarbons and phenols, among which the most important odor substances are hydrogen sulfide, low molecular mercaptans and sulfide dimethyl disulfide. The emission sources of these odorous pollutants are: sulfur recovery unit, desulfurization unit, hydrorefining unit, hydrocracking reaction and fractionation part, alkali washing unit, alkali slag treatment unit, sewage stripping, sewage treatment plant and sulfur-containing sewage, Acid gas, sulfur-containing dry gas, sulfur-containing liquefied gas, low-pressure gas system and various oil storage tanks, etc., have a wide distribution range and almost run through the entire refining production process. The concentrations of main odor pollutants are shown in Table 2.

[0037] Table 2 Concentration of odorous pol...

Embodiment 2

[0046] Embodiment 2: According to the device and process in embodiment 1, the pollutants discharged by a certain urban sewage treatment plant are processed

[0047] The odorous pollutants discharged by a sewage treatment plant in a certain city include: hydrogen sulfide, sulfides, ammonia, indoles, aldehydes, fatty acids, etc. The odor values of each sewage treatment facility are shown in Table 3.

[0048] Table 3 Odor value of urban sewage treatment plants

[0049] pollution source odor value Fluctuation range Grille and pump room 80 35~130 grit chamber 60 30~90 Primary sedimentation pond 60 30~84 Biochemical reaction pool 45 25~100 Secondary sedimentation tank 20 15~30 Sludge dewatering room (belt type) 300 50~500 Sludge dewatering room (centrifugal) 100 50~200

[0050] The main treatment units that discharge malodorous pollutants are all closed or semi-closed, and introduced into the deodorization device o...

Embodiment 3

[0054] Embodiment 3: according to the device and process in embodiment 1, the pollutant discharged by a certain food processing factory is processed

[0055] The production process and sewage treatment process of a food processing factory will discharge a large amount of malodorous substances. The sources of malodorous gases are mainly fermentation tanks, heating tanks, and adjustment tanks, neutralization tanks, aeration tanks, mud storage tanks and dehydration machine rooms of the wastewater treatment system. . The odor values of the main sources of malodorous gas are shown in Table 4.

[0056] Table 4 Odor value of a food factory

[0057] pollution source odor value Fluctuation range Fermentation workshop 280 30~600 heating workshop 160 20~350 Regulation pool 110 19~245 neutral pool 95 25~167 Aeration tank 82 34~196 Mud storage 350 80~690 Dehydration machine room 380 65~730

[0058] According to the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com