Method for quickly and massively separating high purity triptolide from thunder god vine

A technology for triptolide and triptolide, which is applied in the field of rapid and large-scale separation of high-purity triptolide, can solve the problems of small difference between effective dose and toxic dose, difficult control of drug safety, large consumption of toxic solvents, and the like. The process is simple, easy to industrialize production, and the effect of less solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for rapidly and massively separating high-purity triptolide from Tripterygium wilfordii is characterized in that it is carried out according to the following process steps:

[0033] A. Heating extraction: select 30kg of tripterygium wilfordii stem and leaf coarse powder with a particle size of 10 mesh, add methanol at a mass ratio of 1:5, heat at 50°C for 3 hours, remove slag by filtration, recover the filtrate under reduced pressure to remove methanol, and obtain water suspension;

[0034] B. Solvent extraction: Take 10 L of the aqueous suspension obtained in step A, first extract with 20 L of petroleum ether, and then extract the aqueous phase with 30 L of dichloromethane, each extraction 3 times. The petroleum ether layer was discarded after recovery of petroleum ether, and the dichloromethane extracts were combined and concentrated at 50°C to obtain 150 g of dark yellow precipitate (density 1.26).

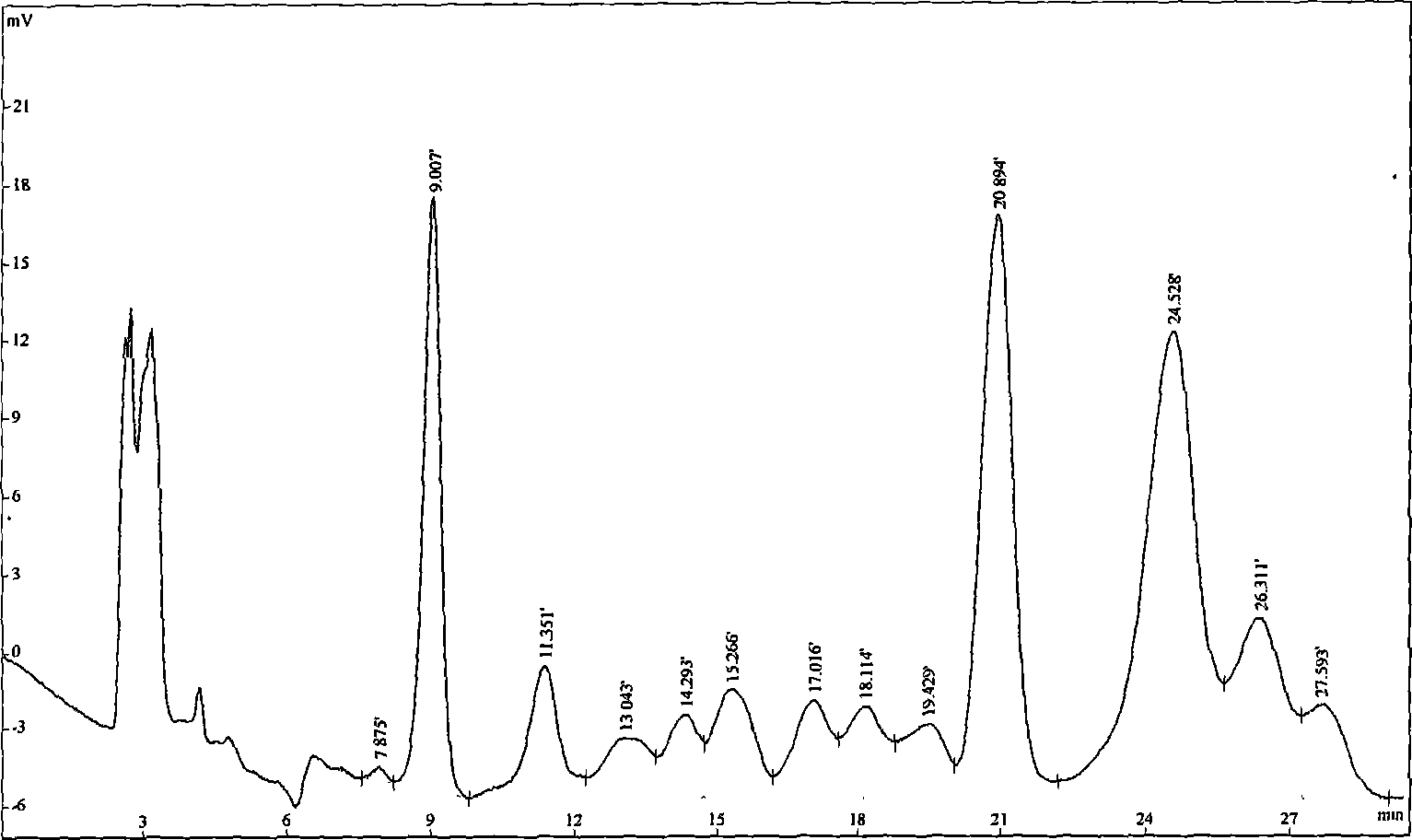

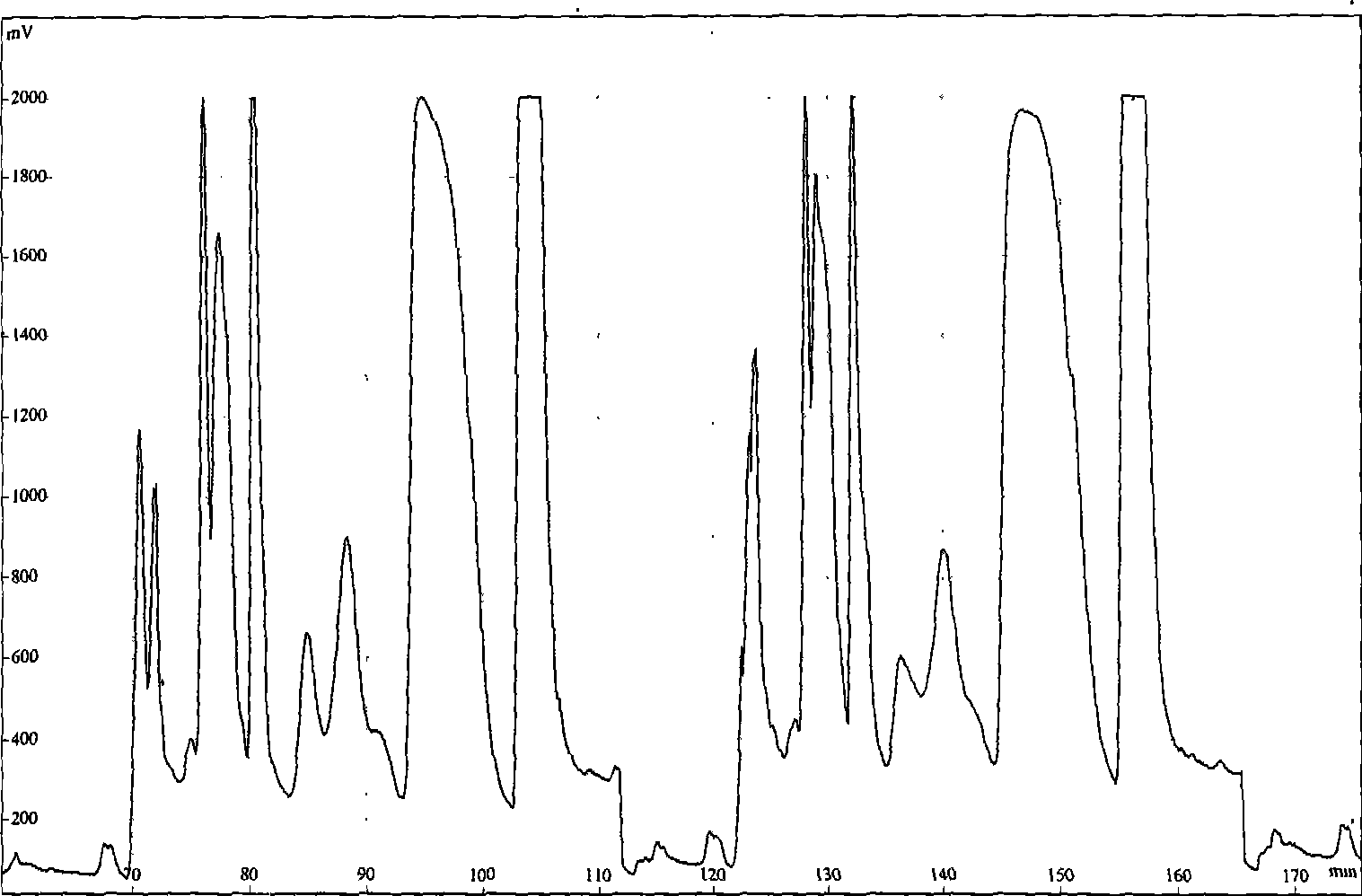

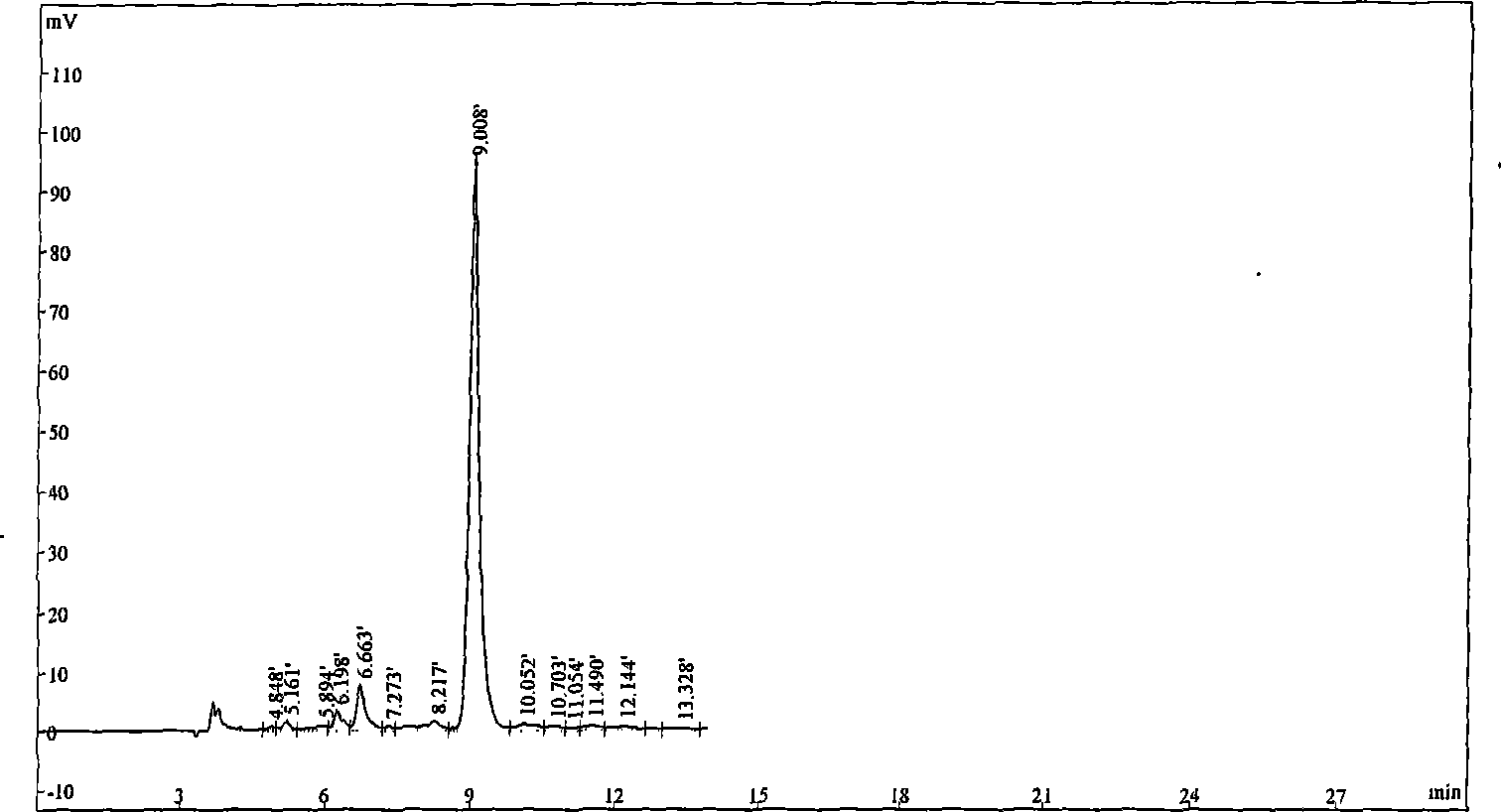

[0035] C. Chromatographic column chromatography: take 20 ...

Embodiment 2

[0040] A method for rapidly and massively separating high-purity triptolide from Tripterygium wilfordii is characterized in that it is carried out according to the following process steps:

[0041] A. Heating extraction: Select 500kg of coarse powder of tripterygium wilfordii with a particle size of 20 mesh, add 95% ethanol at a mass ratio of 1:5, heat at 55°C for 3 hours, filter to remove slag, and recover the filtrate under reduced pressure to remove ethanol After that, an aqueous suspension is obtained;

[0042] B. Solvent extraction: Take 500 L of the aqueous suspension obtained in step A, first extract with 1000 L of petroleum ether, and then extract the aqueous phase with 1500 L of dichloromethane, each extraction 5 times. The petroleum ether layer was discarded after recovery of petroleum ether, and the dichloromethane extracts were combined and concentrated at 55°C to obtain 9000 g of dark yellow precipitate (density 1.26).

[0043] C. Chromatographic column chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com