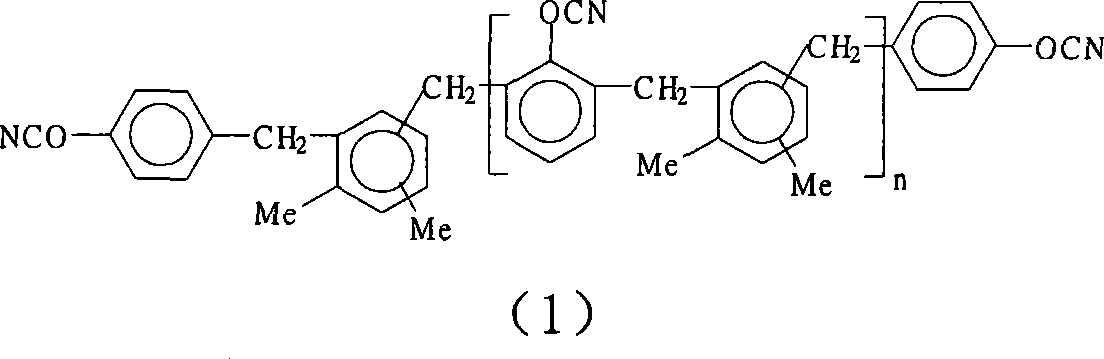

Alkyl xylol type cyanate resin, preparation and uses thereof

A technology of alkylxylene type cyanate ester and hydroxyphenyl alkylxylene resin, which is applied in the field of organic polymer material synthesis, can solve problems such as hindering the popularization and use of resins, and is not very ideal, and achieves low raw material cost and low cost The effect of inexpensive, excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

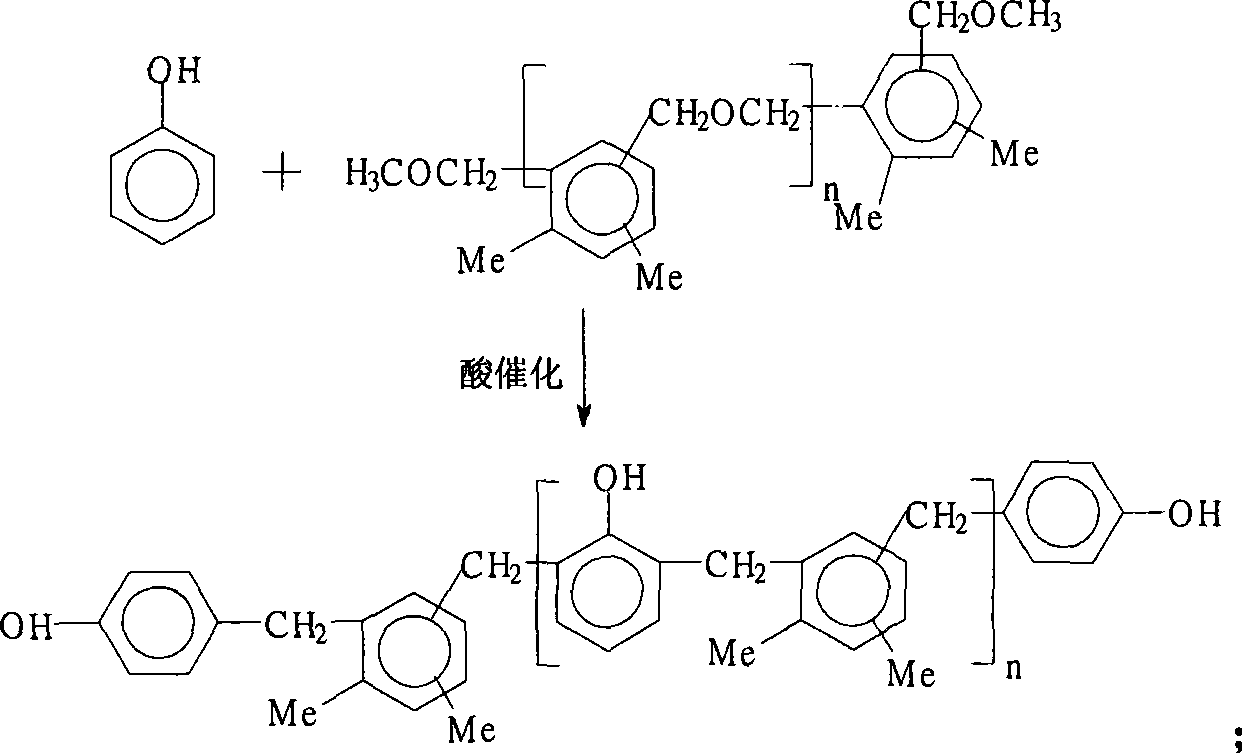

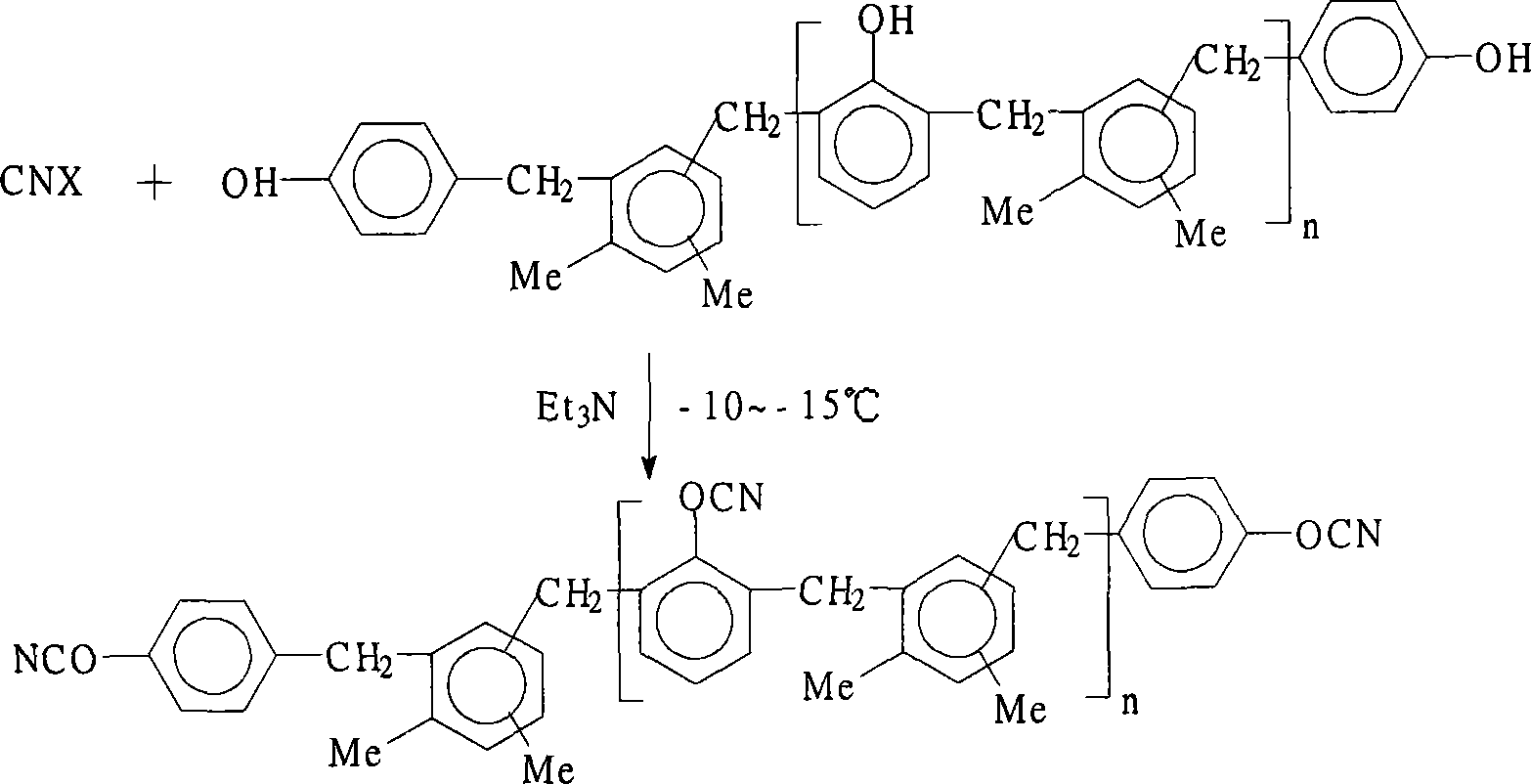

Method used

Image

Examples

Embodiment 1

[0045] The 5000ml three-necked bottle is equipped with a constant pressure funnel, mechanical stirring and condensation device. First put 2000g of phenol and 1800g of methoxyxylyl ether oligomer into the three-necked bottle. Melting, stirring evenly, the system is transparent yellow. First add 9g of p-toluenesulfonic acid catalyst into the system, and the color of the system turns brownish red after stirring. After the system was heated to 70°C, the heating was stopped. At this time, due to the exothermic reaction, the temperature in the system will automatically rise. When the temperature rose to 100°C, bubbles appeared in the system. The temperature of the system spontaneously rises up to about 120°C, and then gradually cools down. At this time, 9 g of p-toluenesulfonic acid is added to the system. When the temperature of the system automatically dropped to 110°C, keep it warm and collect fractions. After 1 hour collection was complete and heating was discontinued. Whe...

Embodiment 2

[0054] The casting body experimental formulation of the alkylxylene type cyanate resin is as follows: the catalysts are cobalt acetylacetonate and nonylphenol, and the dosages are 200ppm and 3% of the quality of the alkylxylene type cyanate resin, respectively. Mix the catalyst and the alkylxylene type cyanate resin evenly, and pour it into the preheated mold. Put the mold into a vacuum oven, depressurize and remove air at 90°C. After the gas in the system is completely removed, solidify. The curing method of alkylxylene type cyanate resin has the following four ways:

[0055] A: 120°C / 2hr+150°C / 4hr

[0056] B: 120°C / 2hr+150°C / 2hr+180°C / 4hr

[0057] C: 120°C / 2hr+150°C / 2hr+180°C / 4hr+200°C / 2hr

[0058] D: 120°C / 2hr+150°C / 2hr+180°C / 4hr+200°C / 2hr+220°C / 2hr

[0059] The physical properties of the cast body obtained are as shown in Table 1:

[0060] Table 1 Properties of alkylxylene type cyanate resin after curing

[0061]

[0062] *1: The test condition is under the state...

Embodiment 3

[0064] The thermal properties of alkylxylene type cyanate resins containing different catalyst systems are shown in Table 2. Wherein I is a catalyst-free system, II is a cobalt acetylacetonate and nonylphenol mixed catalyst system, and III is a manganese acetylacetonate catalyst system.

[0065] Table 2 Thermal properties of alkylxylene type cyanate resins

[0066]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com