Sulfonated mono-layer graphite and polymer compound material and preparation and application thereof

A technology of sulfonated single-layer and composite materials, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high price, affecting device performance, electrode instability, etc., and achieve the effect of cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: slight sulfonated graphite material preparation method

[0027] Functionalized monolayer graphite (average thickness 0.8nm, average area 400μm 2 ) (Carbon, 2004, 42, 2929) (225 mg) was uniformly dispersed in water (225 ml), and ultrasonically dispersed to form a uniform and clear solution. Use 5% sodium carbonate solution to adjust the pH value of the single-layer graphite solution to 9-10. An aqueous solution (67.5 ml) of sodium borohydride (2.7 g) was added dropwise to the above solution, and the reaction was carried out at 80° C. for 90 minutes. During the reaction, a black precipitate appeared. After the reaction, centrifuge, wash with water, leave the solid, and remove the upper liquid. Repeat the operation five times. The solid was re-sonicated in water (225ml). A mixed solution of 2 g of diazonium salt (4-sulfobenzenediazonium chloride), water (200 ml), and hydrochloric acid (0.2 g, 1 N) was added. The reaction was carried out under ice bath f...

Embodiment 2

[0028] Embodiment 2: preparation method of sulfonated graphite material

[0029] Slightly sulfonated monolayer graphite (50mg) was dispersed in 50ml of fuming sulfuric acid, and after reacting at 80°C for 3 hours, nitrous acid (1.15g), p-aminobenzenesulfonic acid (2.886g) and azobisiso Butyronitrile (0.137g) was added to the above reaction solution to react for 2 hours. After the reaction, it was cooled to room temperature and slowly added to water (500ml). Filter with a 0.2μ water membrane, wash the filter residue repeatedly with water and acetone, and dry at 50°C to obtain a sulfonated single-layer graphite material. Elemental analysis shows that the number ratio of sulfur:carbon atoms is 1:48. The maximum solubility of sulfonated monolayer graphite can reach 10mg / ml.

Embodiment 3

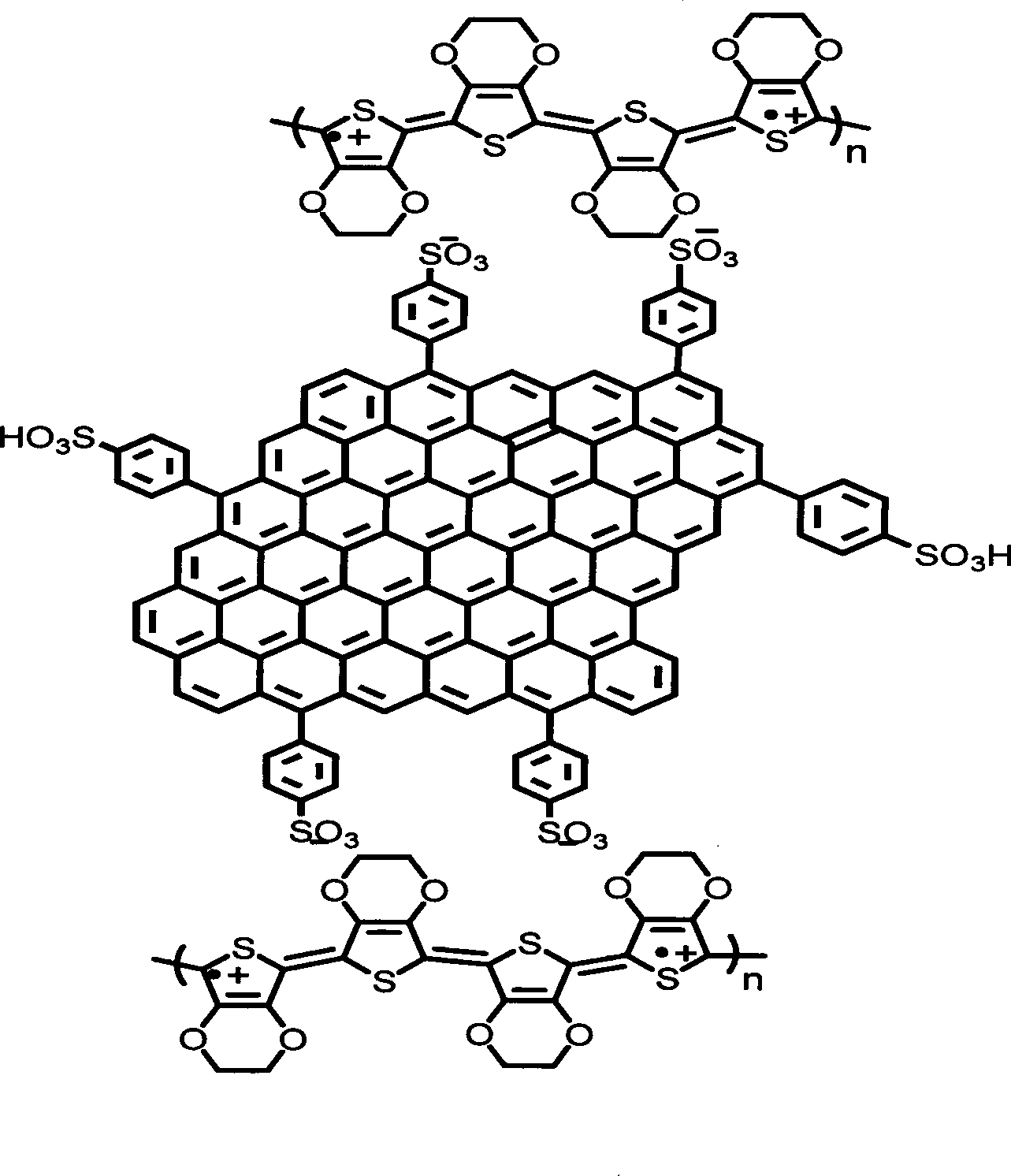

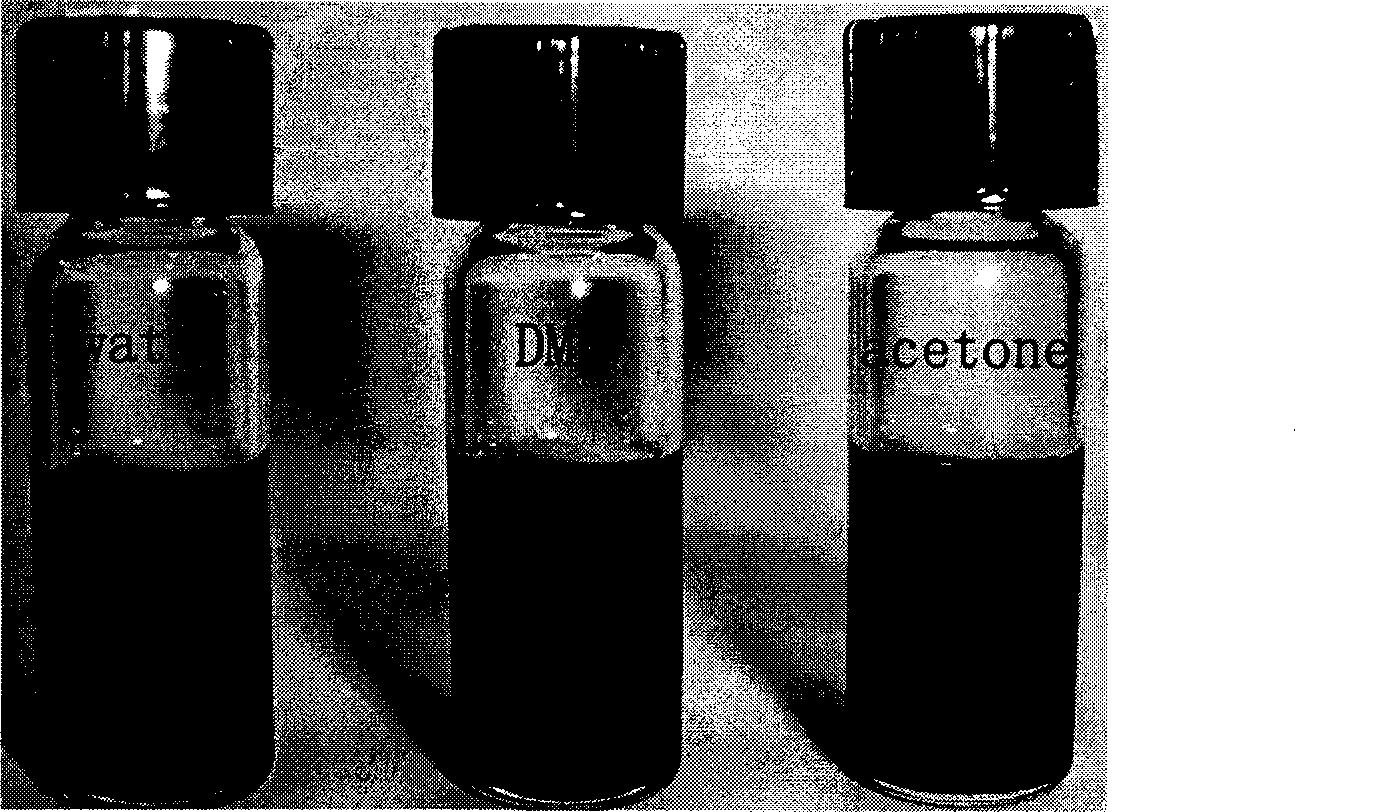

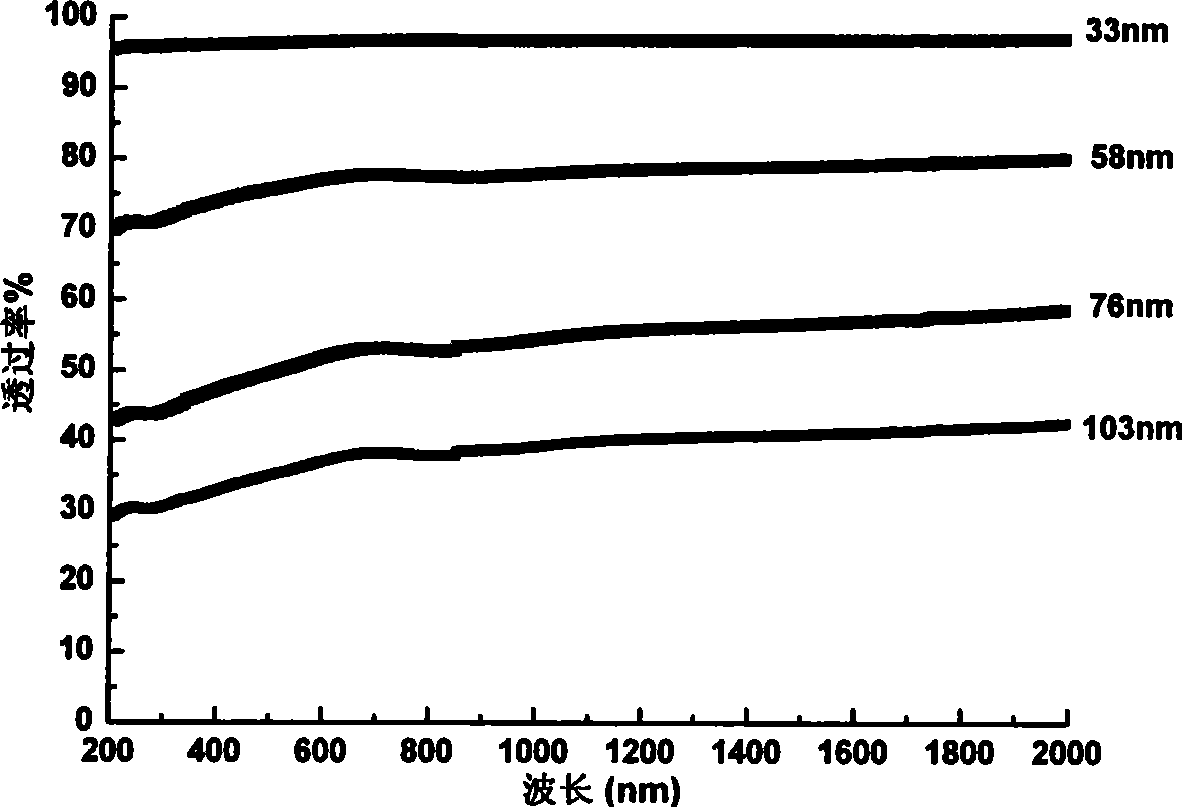

[0030] Embodiment 3: chemical preparation method of sulfonated monolayer graphite / PEDOT composite material

[0031] After the sulfonated monolayer graphite material (10 mg) was ultrasonically dispersed in water (10 ml), EDOT (3,4-ethylenedioxythiophene) (100 mg) and anhydrous ferric sulfate (10 mg) were added to the above solution. React at 50°C for 48 hours. After the reaction, the reaction solution was poured into methanol (100 ml), and stirred vigorously for 1 hour. Filter and wash the filter residue with water and acetone repeatedly until there is no 3,4-ethylenedioxythiophene in the filtrate. After drying, a sulfonated single-layer graphite-doped polyPEDOT composite was obtained. Elemental analysis shows that the ratio of sulfur to carbon atoms is 1:13. 1522cm -1 It is the C=C vibrational absorption peak on PEDOT, 1316cm -1 It is the C-C vibration absorption peak on PEDOT, 1199, 1087cm -1 It is the C-O-C vibration absorption peak on PEDOT, 982, 839689cm -1 It is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com