Rubber-enhanced compatibilizer composition and preparation technology thereof

A technology of rubber reinforcement and preparation technology, which is applied in the field of mineral ultra-fine processing, can solve the problems such as the difficulty of obtaining structural units, and achieve the effects of ensuring uniform powder dispersion, obvious environmental benefits, and simple preparation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

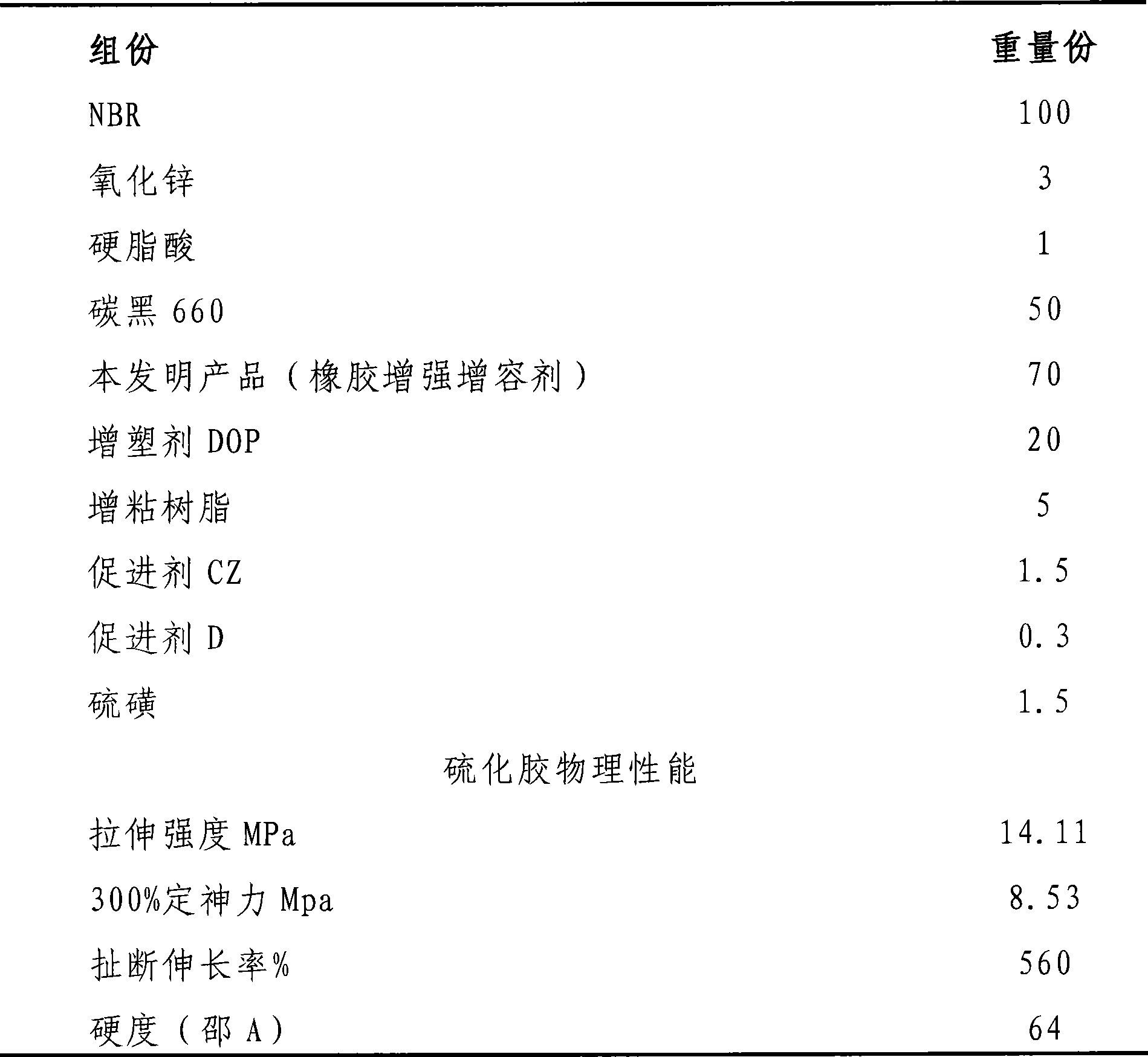

Embodiment 1

[0033] The raw material composition of this embodiment is: 100 kilograms of sorting raw materials, 20 kilograms of auxiliary agent A, 10 kilograms of auxiliary agent B, 10 kilograms of auxiliary agent C and 8 kilograms of auxiliary raw materials, wherein, the sorting raw materials are anthracite, bituminous coal, coke One or more mixtures of carbon, semi-coke, coal tar pitch and coal gangue; the auxiliary agent A is graphite, carbon black, petroleum coke, coal tar pitch or talcum powder, which mainly plays a grinding aid role; the auxiliary agent B is aluminate coupling agent, titanate coupling agent, aluminum-titanium composite coupling agent, silane coupling agent, paraffin, palm oil, aromatic oil, aliphatic oil, naphthenic oil, coal tar, rosin or vaseline , the main function is chemical grafting and surface modification; the auxiliary agent C is coumarone resin, lignin, phenolic resin, stearic acid, zinc stearate, sulfur, zinc oxide or magnesium oxide, and the main function ...

Embodiment 2

[0041] The raw material composition of this embodiment is: 100 kg of sorting raw materials, 0.5 kg of auxiliary agent A, 0.1 kg of auxiliary agent B and 0.1 kg of auxiliary agent C, wherein the sorting raw materials are anthracite, bituminous coal, coke, semi-coke, One or more mixtures of coal tar pitch and coal gangue; the auxiliary agent A is graphite, carbon black, petroleum coke, coal tar pitch or talcum powder, which mainly plays a grinding aid role; the auxiliary agent B is aluminate Coupling agent, titanate coupling agent, aluminum-titanium composite coupling agent, silane coupling agent, paraffin, palm oil, aromatic oil, aliphatic oil, naphthenic oil, coal tar, rosin or vaseline, the main role is chemical Grafting, surface modification; the auxiliary agent C is coumarone resin, lignin, phenolic resin, stearic acid, zinc stearate, sulfur, zinc oxide or magnesium oxide, and its main function is to improve the reinforcing effect of the product .

[0042] The preparation ...

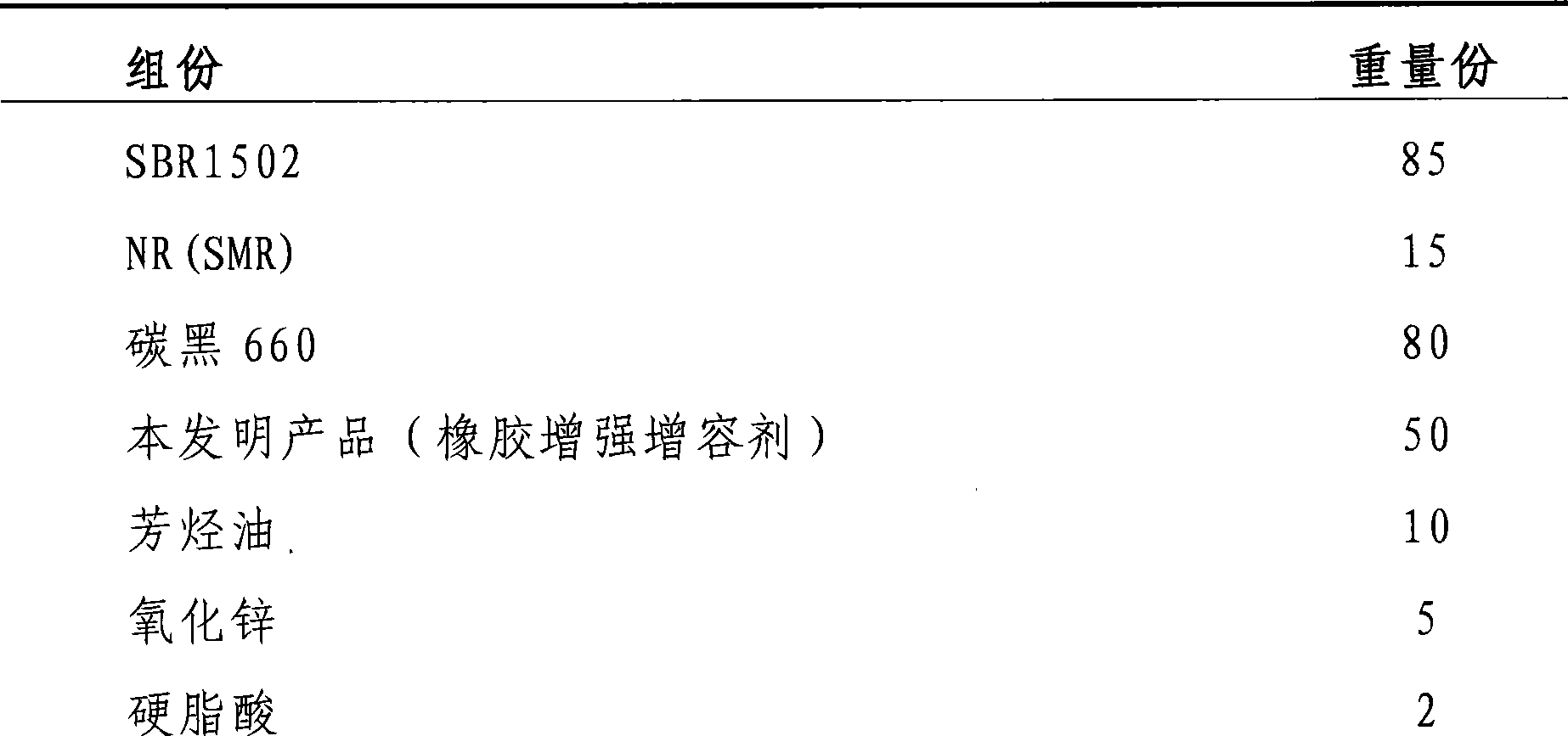

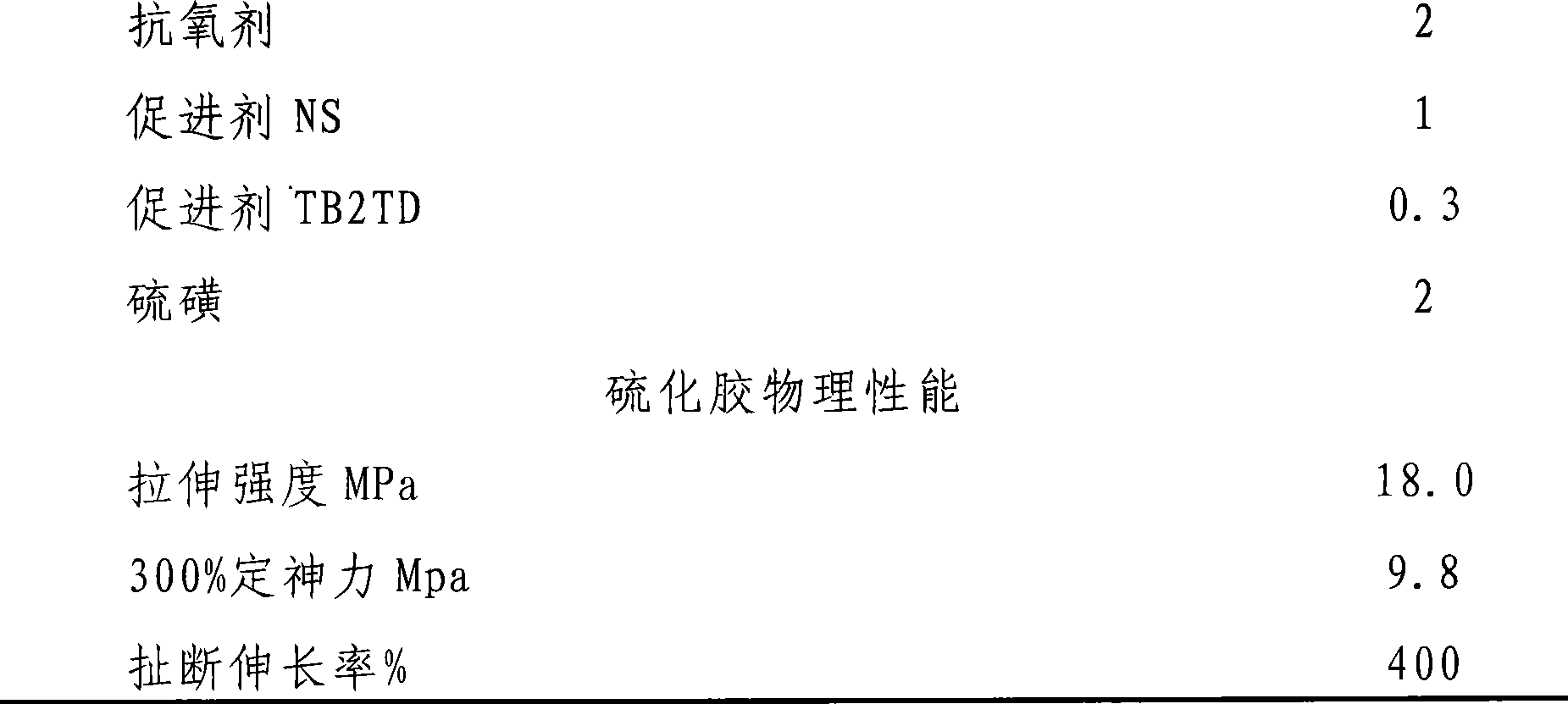

Embodiment 3

[0045] The raw material composition of this embodiment is: 100 kilograms of sorting raw materials, 10 kilograms of auxiliary agent A, 5 kilograms of auxiliary agent B, 5 kilograms of auxiliary agent C and 2 kilograms of auxiliary raw materials, wherein, the sorting raw materials are anthracite, bituminous coal, coke One or more mixtures of carbon, semi-coke, coal tar pitch and coal gangue; the auxiliary agent A is graphite, carbon black, petroleum coke, coal tar pitch or talcum powder, which mainly plays a grinding aid role; the auxiliary agent B is aluminate coupling agent, titanate coupling agent, aluminum-titanium composite coupling agent, silane coupling agent, paraffin, palm oil, aromatic oil, aliphatic oil, naphthenic oil, coal tar, rosin or vaseline , the main function is chemical grafting and surface modification; the auxiliary agent C is coumarone resin, lignin, phenolic resin, stearic acid, zinc stearate, sulfur, zinc oxide or magnesium oxide, and the main function is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com