Preparation method of dental composite resin containing function monomer PMDM and modified hydroxylapatite and use thereof

A technology of hydroxyapatite and functional monomers, applied in dental preparations, dentistry, medical science, etc., can solve the problems of products with excellent comprehensive performance, edge micro-leakage, etc., achieve excellent curing performance, improve interface strength, and improve the preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

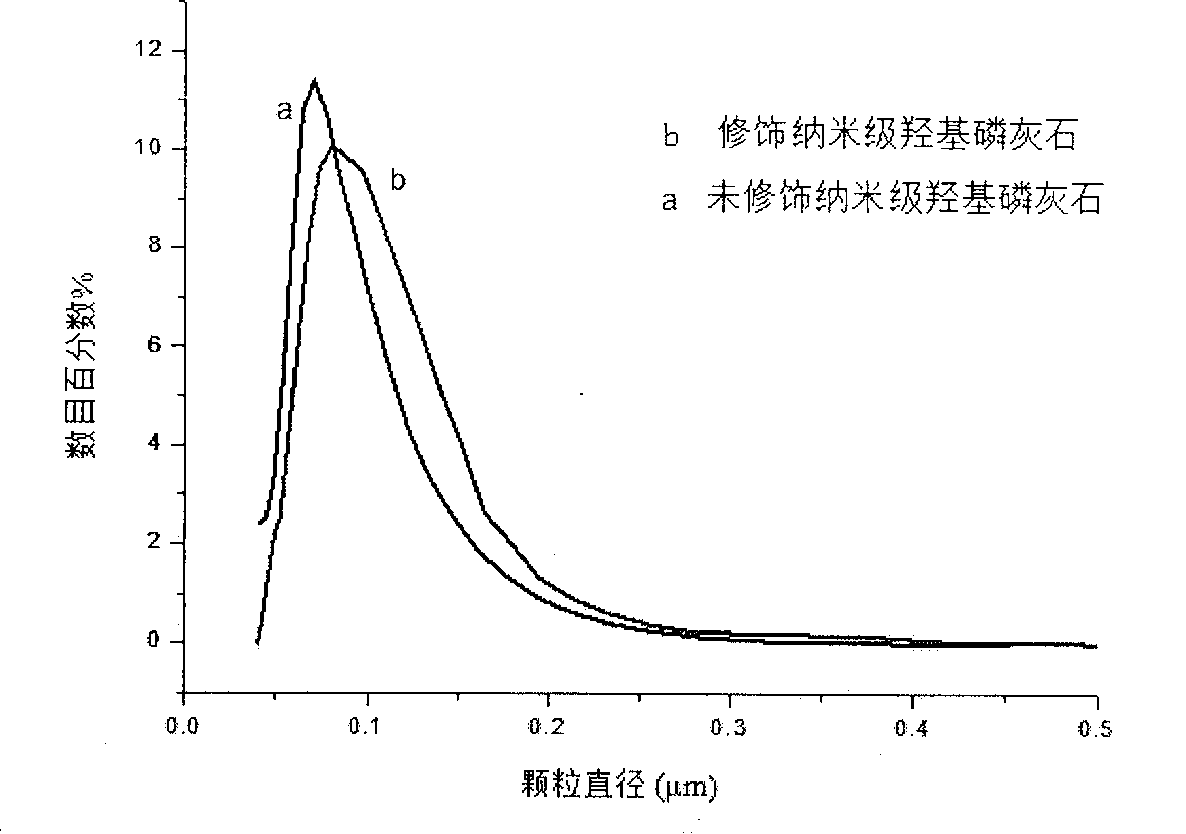

[0042] Add 3g of hydroxyapatite (HPA) into the organic solvent, and then add 0.03g of the polymerization inhibitor methoxyphenol and 0.15g of the catalyst sulfuric acid, and then place it in a constant temperature oven, and make the polymerization inhibitor and the catalyst at 40°C Dissolve, add 5g of methacrylic acid, reflux reaction at 60°C for 2 hours, filter the obtained product while it is hot, extract the filter cake with chloroform for 12 hours, wash with distilled water, dry, and obtain modified hydroxyapatite (HPA- unsaturated). Such as figure 1 Shown are the particle size distribution plots of modified and unmodified hydroxyapatite.

[0043] Add 3% functional monomer PMDM in mass parts to the matrix resin Bis-GMA, stir evenly, add 0.01g photosensitizer CQ and 0.01g organic amine activator DMAEMA, stir evenly, add 8g micron-level and 2g nano-level modification respectively hydroxyapatite, diluted with 1.7g of ethanol solvent, placed in a vacuum oven at 40°C for 2 ho...

Embodiment 2

[0046]Add 4g of hydroxyapatite (HPA) to the organic solvent, and then add 0.06g of inhibitor hydroquinone and 0.28g of catalyst p-toluenesulfonic acid in sequence, place it in a constant temperature oven, and make the polymerization inhibitor at a temperature of 50°C. Dissolve the agent and the catalyst, add 8g methyl methacrylate, reflux at 65°C for 2.5 hours, filter the resulting product while it is hot, extract the filter cake with benzene for 15 hours, wash it with distilled water, and dry it to obtain the modified hydroxyphosphorus Greystone (HPA-unsaturated).

[0047] Add 7% functional monomer PMDM in mass parts to the matrix resin Bis-GMA, stir evenly, add 0.05g photosensitizer CQ and 0.05g organic amine activator DMAEMA, stir evenly, add 14g micron-level and 6g nano-level modification respectively hydroxyapatite, diluted with 2.5g of acetone solvent, placed in a vacuum oven, placed at 45°C for 2.5 hours, until the solvent evaporated and the air bubbles were eliminated,...

Embodiment 3

[0050] Add 5g of hydroxyapatite (HPA) into the organic solvent, and then add 0.08g of polymerization inhibitor phenothiazine and 0.45g of catalyst sodium methoxide in sequence, place in a constant temperature oven, and make the polymerization inhibitor and catalyst Dissolve, add 10g of acrylic acid, reflux at 70°C for 2.5 hours, filter the obtained product while it is hot, extract the filter cake with toluene for 25 hours, wash with distilled water, and dry to obtain modified hydroxyapatite (HPA-unsaturated) .

[0051] Add 10% of the functional monomer PMDM in mass parts to the matrix resin Bis-GMA, stir evenly, add 0.10g of photosensitizer CQ and 0.10g of organic amine activator DMAEMA, stir evenly, add 12g of micron-level and 8g of nano-level modification respectively hydroxyapatite, diluted with 2.0g ether solvent and placed in a vacuum oven at 50°C for 2.5 hours, until the solvent evaporated and air bubbles were eliminated to obtain a dental composite resin.

[0052] Use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com