Purification method of sulphur-containing flue-gas

A sulfur-containing flue gas and flue gas technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of inability to intercept fine dust in sulfur-containing flue gas, increase energy consumption, and complicate the purification process, etc., to achieve Good resistance to high temperature oxidation/vulcanization, reduced running strength and difficulty, and good pore structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 The method of the present invention is used to purify sulfur-containing flue gas

[0021] Using an iron-aluminum filter with FeAl intermetallic compound filter material as the filter element, the total amount of 13m 3 The high-temperature sulfur-containing flue gas passes through the cyclone dust collector, and after preliminary slag discharge, it directly enters the iron-aluminum filter; the filtration pressure is controlled at 0.10MPa, and the high-temperature sulfur-containing flue gas passes through the FeAl intermetallic compound filter element to achieve its solid gas In the separation process, the gas after solid-gas separation is absorbed by 4L of sulfuric acid with a concentration of 93%.

[0022] As a comparison, a cloth bag filter is used instead of the FeAl intermetallic compound filter element to filter sulfur-containing flue gas under the same conditions, and the rest of the steps are the same as above.

[0023] The sulfuric acid after absorbing...

Embodiment 2

[0028] Example 2 The method of the present invention is used to purify sulfur-containing flue gas

[0029] Using an iron-aluminum filter with FeAl intermetallic compound filter material as the filter element, the total amount of 13m 3 The high-temperature sulfur-containing flue gas passes through the cyclone dust collector, and after preliminary slag discharge, it directly enters the iron-aluminum filter; the filtration pressure is controlled at 0.40MPa, and the high-temperature sulfur-containing flue gas passes through the FeAl intermetallic compound filter element to achieve its solid gas In the separation process, the gas after solid-gas separation is absorbed by 4L of sulfuric acid with a concentration of 93%. After 2 days of filtration, control the backwash pressure to 0.50MPa, use high-temperature filter air to backwash the FeAl intermetallic compound filter element, and continue to filter after backwashing for 4 minutes; most of the dust will be eliminated at this stage...

Embodiment 3

[0032] Example 3 The method of the present invention is used to purify the sulfur-containing flue gas produced by the smelting of molybdenum concentrate

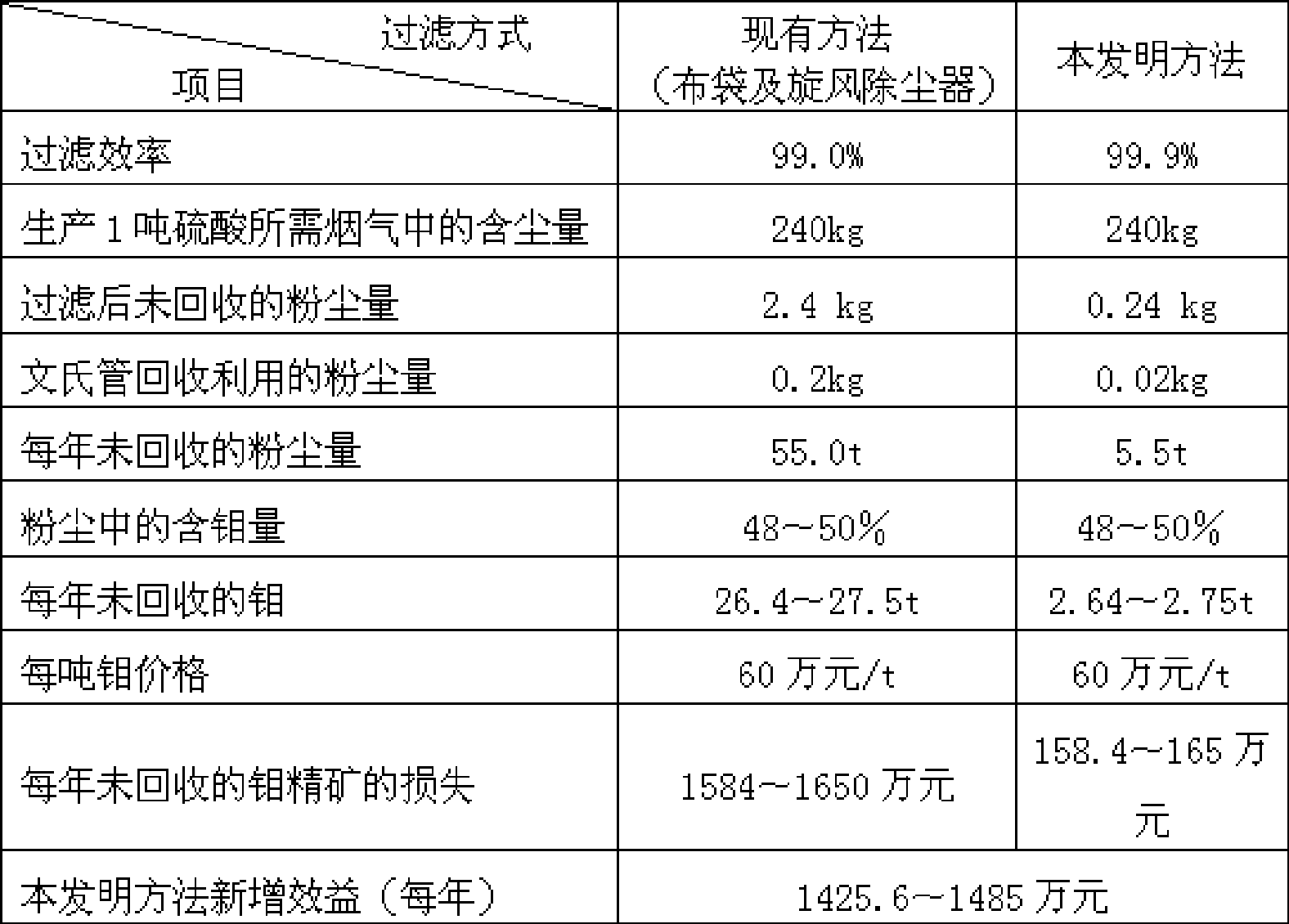

[0033] The sulfur-containing flue gas produced by the smelting of molybdenum concentrate is purified by the method of the present invention to produce sulfuric acid and recover molybdenum ore. The annual output of sulfuric acid is 25000t. And compared with existing methods, the results are shown in Table 2.

[0034] Table 2

[0035]

[0036] It can be seen from Table 2 that the method of the present invention obviously improves the recovery rate of molybdenum in the smelting of molybdenum concentrate, can produce huge economic benefits, and has broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com