High-temperature-resistant and H2S-corrosion-resistant sintered metal filtering element and application

A technology of sintered metal and filter elements, which is applied in the field of sintered metal materials, can solve the problems of poor corrosion resistance, poor thermal shock resistance and pressure fluctuation resistance, and poor high temperature oxidation resistance of iron-three-aluminum filter elements. The effect of running intensity and difficulty, low production cost and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 sheet filter element

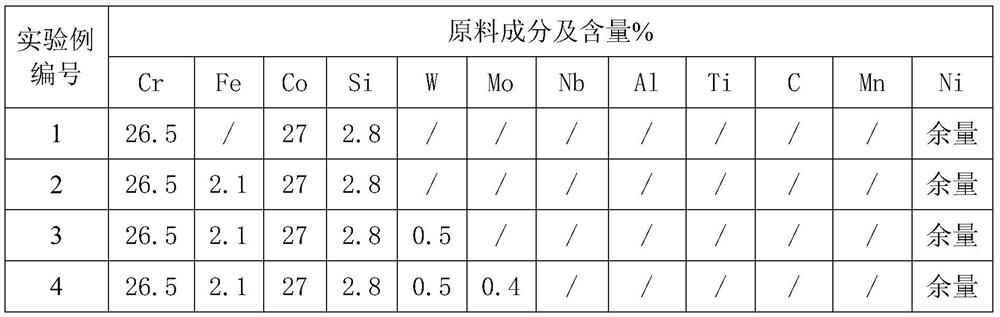

[0037] Table 1 The chemical composition table (by mass percentage) of the raw material sintered metal used in the embodiment of the present invention

[0038]

[0039]

[0040] Note: " / " means no item.

[0041] The first step is to prepare a sheet-like support:

[0042] In the above experimental examples 1 to 10, the Ni powders are all irregular and amorphous, and the particle size of the raw material powder is 80-150 mesh. Listed in Table 1, the raw materials of Experimental Examples 1 to 10 were mechanically mixed respectively. After uniform mechanical mixing, the powders of Experimental Examples 1 to 10 were granulated, and then dried. The drying temperature was set at 85° C. and the drying time was set at 4 hours. In test examples 1 to 10, potato starch was used as a granulating agent during granulation, and the amount of potato starch added was 15% of the total mass of the mixed powder. Afterwards, th...

Embodiment 2

[0053] The preparation of embodiment 2 tubular filter element

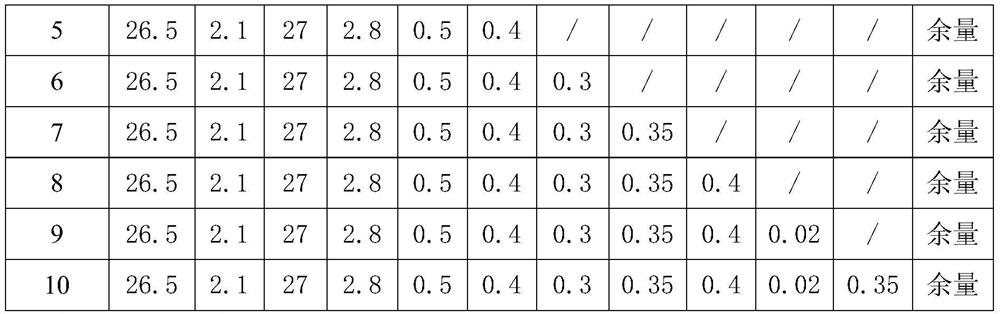

[0054] Table 3 The chemical composition table (by mass percentage) of the raw material sintered metal used in the embodiment of the present invention

[0055]

[0056] Note: " / " means no item.

[0057] The first step is to prepare the tubular support:

[0058] In the above experimental examples 1 to 10, the Ni powders are all irregular and amorphous. Listed in Table 1, the raw materials of Experimental Examples 1 to 10 were mechanically mixed respectively. After uniform mechanical mixing, the powders of Experimental Examples 1 to 10 were granulated, and then dried. The drying temperature was set at 85° C. and the drying time was set at 4 hours. In test examples 1 to 10, potato starch was used as a granulating agent during granulation, and the amount of potato starch added was 15% of the total mass of the mixed powder. After that, the powders of Experimental Examples 1 to 10 were respectively packed into col...

Embodiment 3

[0069] Embodiment 3: The filter element prepared in embodiment 1 is used to purify sulfur-containing gas.

[0070] The high temperature and H2S corrosion resistant sintered metal filter element prepared in Example 1 was made into a filter. After the high-temperature sulfur-containing gas passes through the cyclone dust collector, the temperature is 310°C, the SO2 content is 1.7%, and the dust content is 18g / m3. Enter the filter, control the filter pressure difference to 2KPa, the gas temperature obtained after solid-gas separation is 310°C, the SO2 content is 1.6%, and the dust content is 0.03g / m3. After the purified gas is absorbed by sulfuric acid with a concentration of 93%, the color of sulfuric acid is clear.

[0071] After the above filter element has been used for 24 hours, use compressed air to back-flush and clean the high-temperature and H2S-resistant sintered metal filter element. And the filtration accuracy has not been significantly reduced.

[0072] As a compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com