Aspergillus niger strain for high yield of chlorogenic acid hydrolase and use thereof

A technology of Aspergillus niger strain and chlorogenic acid, which is applied in hydrolytic enzymes, fungi, and microbial-based methods, can solve the problems of unstable yield and conversion rate, lack of basic data in applied research, etc., and achieve easy cultivation and enzyme production High efficiency and fast growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

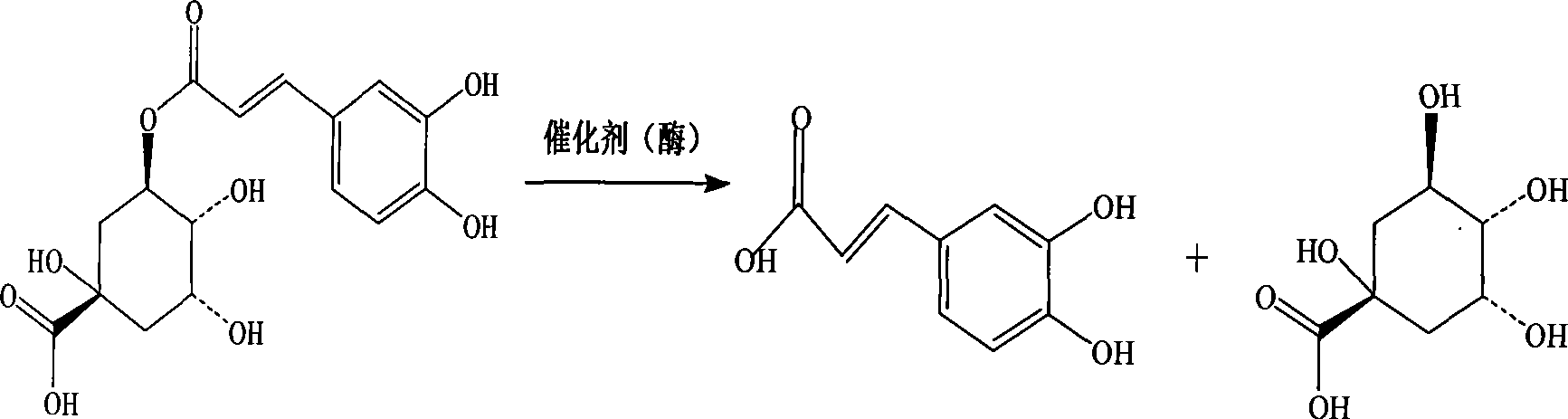

Method used

Image

Examples

Embodiment 1

[0029] This example illustrates the screening process for Aspergillus niger LN-1.

[0030] Collect soil samples from many plants rich in chlorogenic acid, put them into a conical flask with 50mL of sterile water, add about 20 glass beads, shake vigorously for 20 minutes to completely mash the soil, and let it stand still. Add 1mL of soil sample suspension into each 50mL sterile water Erlenmeyer flask, put it into a constant temperature shaking incubator and cultivate it at 37°C for 2 days. Take the suspension and spread it on the primary screening plate medium to carry out the primary screening of the enzyme-producing strains. The composition of the primary screening medium is: dipotassium hydrogen phosphate 1.0%, potassium dihydrogen phosphate 0.5%, ammonium sulfate 0.1%, sodium nitrate 0.05%, magnesium sulfate 0.05%, ferrous sulfate 0.005%, zinc sulfate 0.005%, agar 5 %, pH6.5, and added 1% chlorogenic acid and 0.002% bromocresol green. The temperature is 35°C, and the cul...

Embodiment 2

[0036] This example illustrates the method of using Aspergillus niger LN-1 to carry out fermentation and enzyme production to produce chlorogenic acid hydrolase, and to obtain caffeic acid and quinic acid by directional enzymatic hydrolysis.

[0037] Medium composition: dipotassium hydrogen phosphate 0.1%, potassium dihydrogen phosphate 0.1%, ammonium sulfate 0.1%, sodium nitrate 0.01%, magnesium sulfate 0.01%, ferrous sulfate 0.001%, zinc sulfate 0.001%, pH 5.0, and added 0.5 %Chlorogenic acid.

[0038] The spore suspension (concentration) of Aspergillus niger LN-1 was inoculated in the culture medium at an inoculum size of 1%, and cultured aerobically at a temperature of 25° C. for 1 day, that is, the enzyme production ended.

[0039] The chlorogenic acid is dissolved and prepared to be 1%, and the pH is adjusted to 4.0 with NaOH or HCl solution, which is used as the substrate of the enzyme-catalyzed reaction. Add the substrate solution to the crude enzyme solution or wet b...

Embodiment 3

[0041] The method of this embodiment is the same as that of Embodiment 2, and the parameters of the method used are changed.

[0042] Medium composition: dipotassium hydrogen phosphate 1.0%, potassium dihydrogen phosphate 0.5%, ammonium sulfate 0.1%, sodium nitrate 0.05%, magnesium sulfate 0.05%, ferrous sulfate 0.005%, zinc sulfate 0.005%, pH 6.0.

[0043] The spore suspension (concentration) of Aspergillus niger LN-1 was inoculated in the culture medium with an inoculum size of 2%, and cultured aerobically at a temperature of 35° C. for 4 days, that is, the enzyme production ended.

[0044] The chlorogenic acid was dissolved and prepared at 3%, which was used as the substrate of the enzyme-catalyzed reaction. Add the substrate solution to the crude enzyme solution or wet bacteria obtained by filtering the fermentation broth, and adjust the pH to 6.5 with NaOH or HCl solution, at 35°C, with a rotation speed of 150r / min, and react for 24 hours to hydrolyze chlorogenic acid to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com