Method for immobilizing white rot fungi by using bacteria cellulose film as vector

A technology of bacterial cellulose membrane and white rot fungi, applied in the field of applied microorganisms and cell engineering, can solve the problems of large influence of white rot fungi activity, complicated preparation process, low immobilization efficiency, etc., and achieves low environmental impact and biological stability. Strong and good mass transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

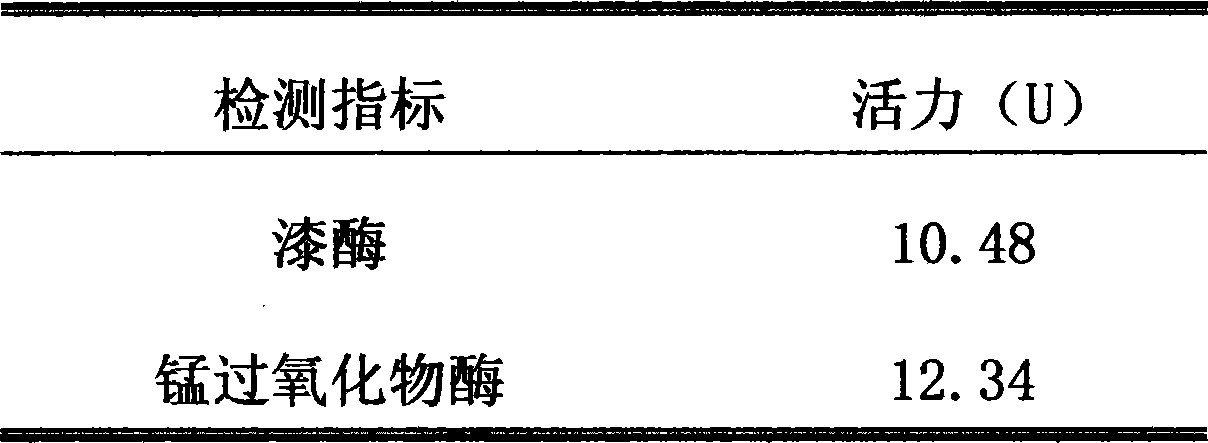

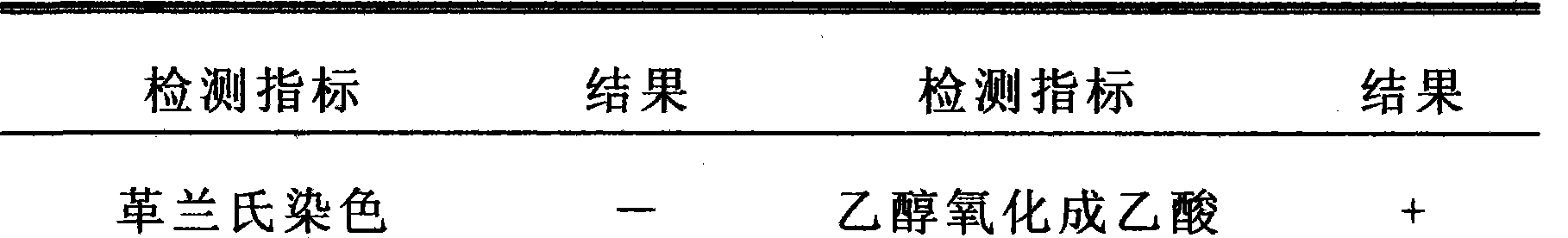

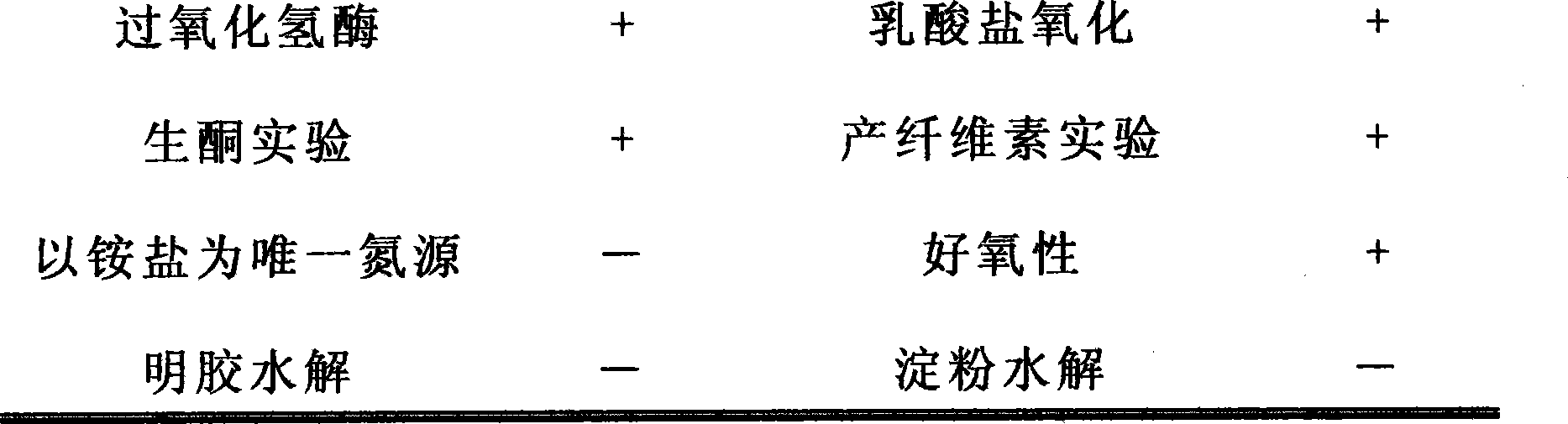

[0041] Isolation and identification of white rot fungi and preparation of spore liquid:

[0042] A. Isolation and identification of white rot fungi: Take 2 g of rotten wood and add it to 100 mL of sterilized liquid medium, place it in a biochemical incubator for constant temperature cultivation at 30 ° C, and observe the growth of bacteria in the medium at any time; the liquid culture The percentages of each component in the base to the mass of the liquid medium are: KH 2 PO 4 0.02%, MgSO 4 ·7H 2 O 0.005%, CaCl 2 0.001%, Glucose 1%, NH 3 Cl 0.02%, H 2 o 2 0.05%, 0.028% sodium tartrate, 0.054% sodium succinate, 0.05% potato extract by volume in the liquid culture medium, sterilized at 121°C for 30 minutes; after 48 hours, take 10 mL of the culture solution for repeated enrichment culture, After 3 times of enrichment culture, the final enrichment solution was taken and cultured on a fixed medium plate; the percentages of each component in the solid medium to the mass of...

Embodiment 2

[0045] Preparation of bacterial cellulose membrane:

[0046] A. Isolation and identification of Acetobacter xylinum (Acetobacter xylinum): Dilute vinegar unstrained spirits 100 times and inoculate in 50mL enrichment medium. %; yeast extract 0.5%; sodium acetate 0.2%; CaCO 3 1%; use acetic acid to adjust the pH to 5.0; after sterilizing at 121°C for 30 minutes, add absolute ethanol with a volume percentage of 2% and nystatin with a mass percentage of 0.5%. Cultivate at ℃ for 5 days, and those with milky white colloidal film on the liquid surface are positive. Peel off the gel film on the surface of the enrichment medium, and stick this film carefully on the first separation medium plate; the percentages of each component in the separation medium mass in the separation medium are: glucose 5% ; Peptone 0.5%; Yeast extract 0.5%; Na 2 HPO 4 12H 2 O 0.2%; KH 2 PO 4 0.1%; MgSO 4 ·7H 2 O0.025%; 0.2% citric acid; 2% agar; pH5.8; After the plate was cultured at 28°C for 48 h...

Embodiment 3

[0049] Modification of bacterial cellulose membrane:

[0050] In a 500mL Erlenmeyer flask with stopper, add 20mL of epichlorohydrin, 5mL of absolute ethanol, 1mL of perchloric acid, 3mL of distilled water, dilute to 100mL with toluene, shake well, add 2g of bacterial cellulose obtained in Example 2 The membrane was heated in a constant temperature water bath at 60°C for 4 hours. After the reaction was complete, the membrane was taken out and washed with acetone to remove residual small molecule organic matter on the membrane, and then dried at 80°C. Put the dried film into another 500mL Erlenmeyer flask, add ethylenediamine 6mL, distilled water 100mL, shake fully, heat in 80°C constant temperature water bath for 4 hours, then take out the film and wash it with distilled water until neutral, then After washing with 1 wt% hydrochloric acid, it was still washed with distilled water until neutral, finally rinsed with acetone, and dried naturally to obtain the modified bacterial ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com