Microwave apparatus and method for synthesizing molecular sieve film

A technology of microwave devices and molecular sieves, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

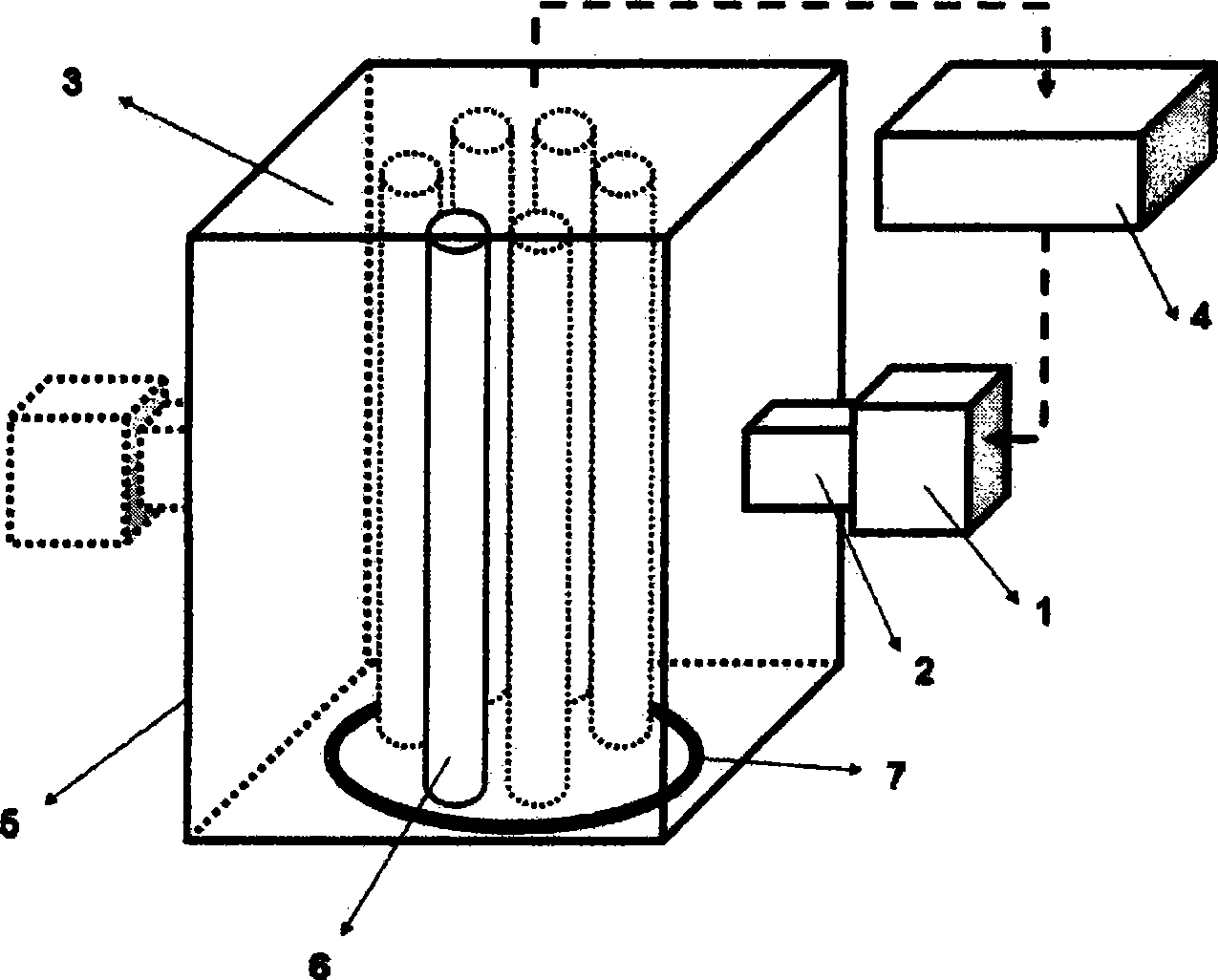

[0028] Such as figure 1 The microwave device for synthesizing molecular sieve membranes of the present invention is composed of a microwave power source 1 , a microwave transmission system 2 , a microwave reactor 3 and a control system 4 . The power of the microwave power source 1 is controlled by the control system 4, and enters the microwave cavity 5 of the microwave reactor 3 via the microwave transmission system 2; the microwave transmission system 2 adopts a known coaxial cable or a rectangular waveguide. The microwave cavity 5 is a single-mode or multi-mode microwave cavity closed by a metal wall, and its three-dimensional size is mainly determined by the size of the object to be processed (the size of the object to be processed determines the size of the reactor), the power density and the cavity mode. How much and distribution to determine. The microwave reactor 3 can be connected with 1 to 30 microwave power sources 1 and the microwave transmission system 2 at differ...

Embodiment 2

[0033] use figure 1 The device synthesizes the molecular sieve membrane, and the specific steps are:

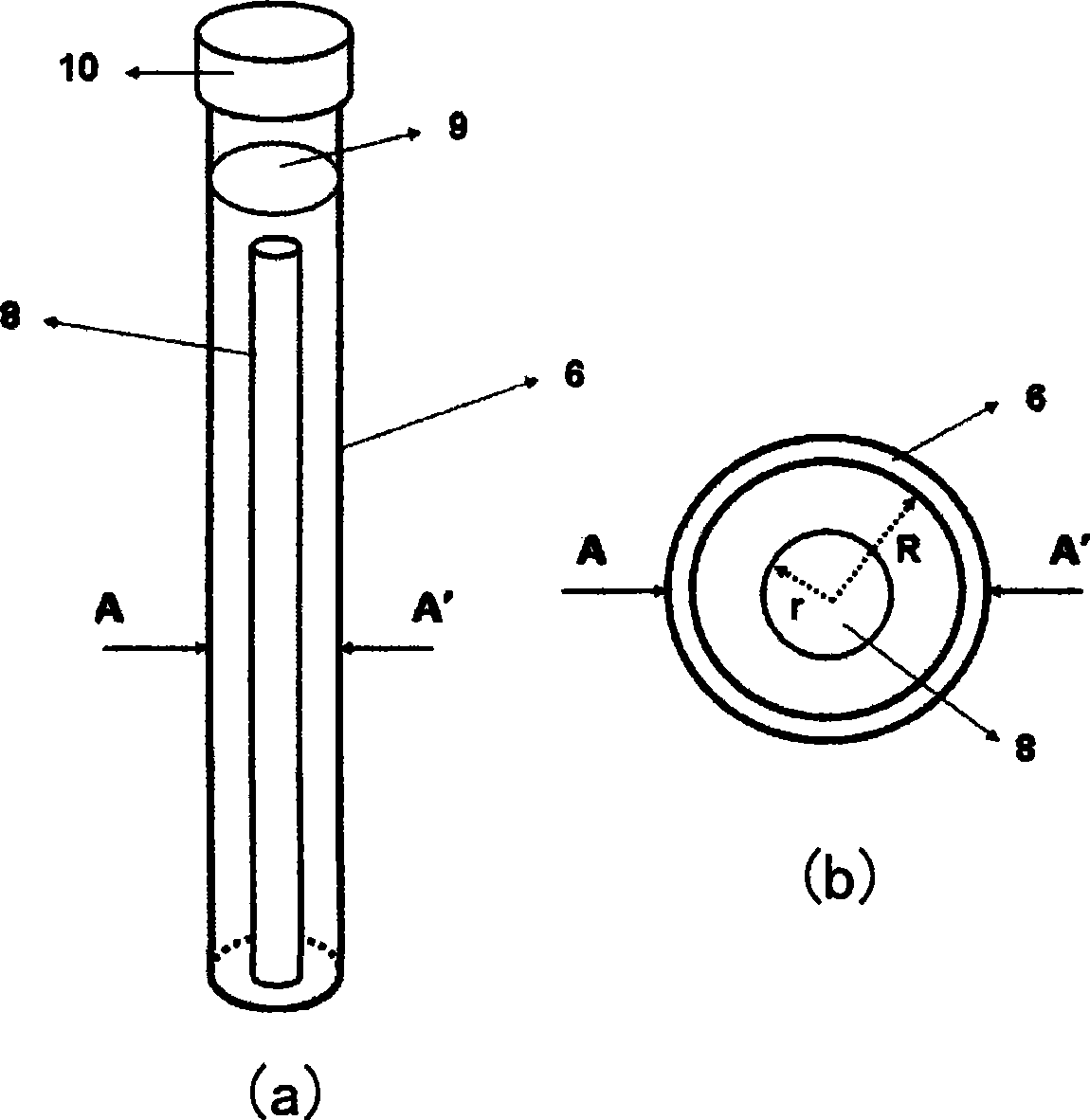

[0034] (a) Place the tubular carrier 8 (such as porous ceramics, porous metal, porous carbon material carrier, etc.) used for synthesizing the molecular sieve membrane in the reaction kettle 6, add the synthesis liquid required for the synthesis, and then seal it with the lid of the kettle.

[0035]Synthetic liquid is made by mixing silicon source, aluminum source, mineralizer, structure directing agent and water; silicon source can be sodium silicate, white carbon black, tetraethyl orthosilicate, orthomethyl silicate, silica sol or / and silicic acid; the aluminum source can be sodium aluminate, sodium metaaluminate, aluminum isopropoxide, aluminum flakes or / and aluminum powder; the mineralizer can be hydrofluoric acid, ammonium fluoride, sodium hydroxide or / and hydrogen Potassium oxide; the structure directing agent can be organic ammonium, quaternary ammonium salt, alcohol...

Embodiment 3

[0041] Comparison of conventional heating, household microwave heating, and microwave device of the present invention for synthesizing type A molecular sieve membrane.

[0042] The type A molecular sieve membrane was synthesized by microwave heating and conventional heating respectively. Wherein, the microwave synthesis is carried out in the household microwave oven and the microwave device of the present invention respectively. Specifically, the microwave device has the following characteristics: a rectangular multi-mode resonant cavity is adopted, and the cavity size is: 50cm long, 50cm wide, and 120cm high; 7 and 8 700w magnetrons are placed on the two sides of the cavity respectively. Tube.

[0043] The separation performance of the synthesized molecular sieve membrane was characterized by measuring the pervaporation dehydration performance of 90% ethanol solution at 65°C.

[0044] Table 1 Comparison Results

[0045]

[0046] As can be seen from Table 1, compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com