Method for producing oxidized pellet using organic binder fully instead of bentonite

An organic binder and oxidizing pellet technology, which is applied in the field of iron and steel metallurgy, can solve the problems of difficult dispersion, low qualification rate of green balls, and reduced strength of finished balls, etc. The effect of increased ball rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

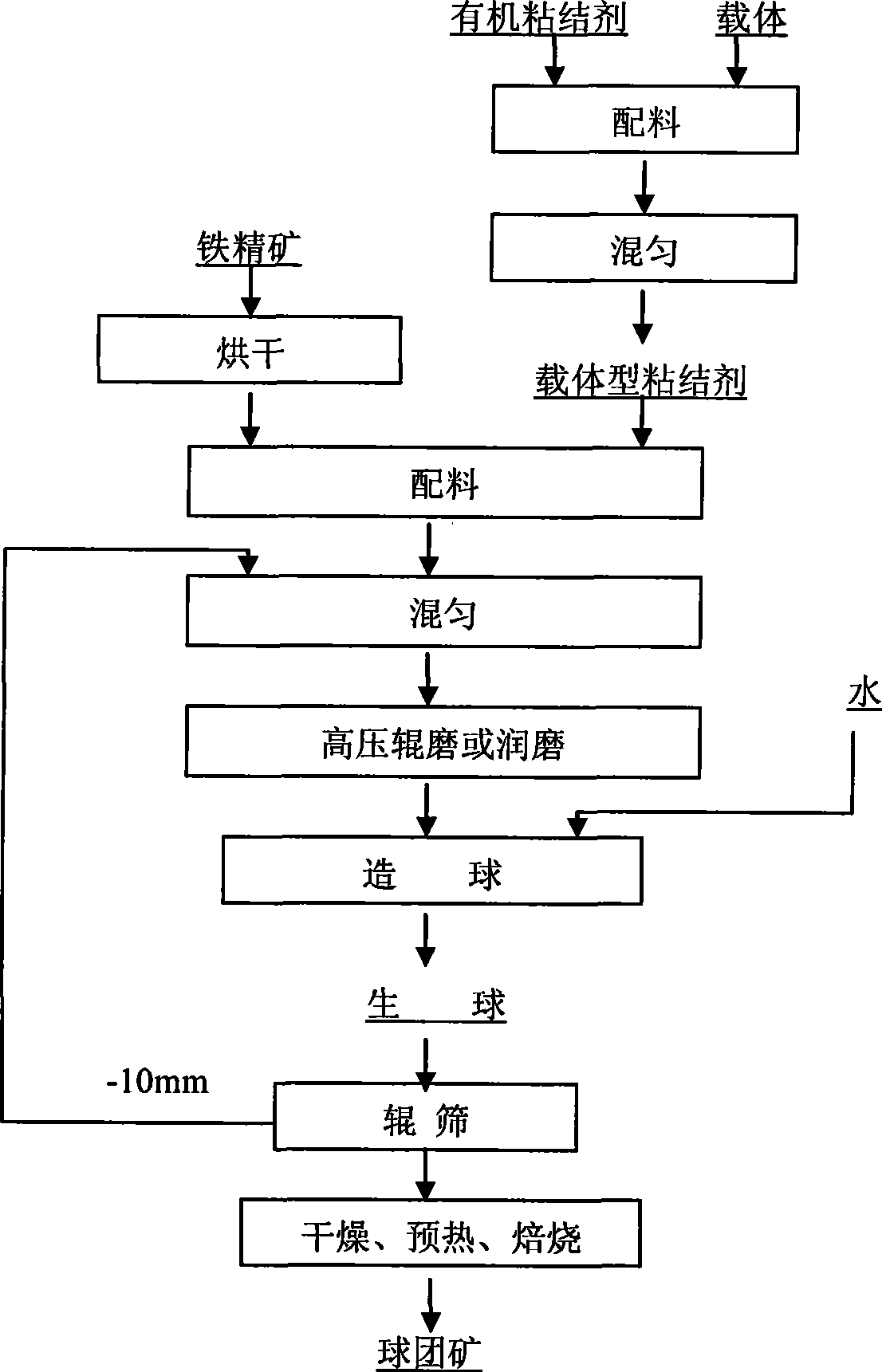

Image

Examples

preparation example Construction

[0036] (2) Preparation of carrier-type organic binder

[0037] Add the organic binder to the carrier, the organic binder / carrier ratio is 1 / 50 to 1 / 10 (depending on the amount of the organic binder and the amount of the carrier binder added), the organic binder and The carrier is mixed evenly under the action of stirring to prepare a carrier-type organic binder with an organic binder mass fraction of 2-10%.

[0038] (3) Preparation of pellets

[0039] Dry the iron concentrate until the water content is 6-8%, add 1%-2.5% carrier-type organic binder to the iron concentrate, mix the iron concentrate and binder, and moisten the mixture The mechanical action of grinding or high-pressure roller mill, and then send the mixture to the pelletizing disc to make green balls with a diameter of 10-16mm. Roasting can use shaft furnace, belt machine or grate machine-rotary kiln process. See attached for specific process figure 1 . Taking the grate machine-rotary kiln pellet production p...

Embodiment 1

[0042] Embodiment 1: adopt the iron ore concentrate with excellent consolidation performance, the weight ratio of organic binder and carrier iron ore concentrate is 6:94, add the carrier type binder of 1.0% (weight) (can be calculated to obtain organic binder The agent consumption is 6 / 100 * 1.0%=0.06%) to replace 2% bentonite, adopts the high-pressure roller mill process, the mixture moisture before the roller mill is 6.5% (weight), preheating temperature 980 ℃, roasting temperature 1250 ℃. The pellet indicators are: the drop strength of green balls is 5.5 times / (0.5m·piece), the compressive strength is 12.6N / piece, the burst temperature is greater than 600°C, the strength of preheated balls is 483N / piece, and the strength of finished balls is 2563N / piece. Compared with pellets with bentonite as binder, iron grade increased by 1.2%, SiO 2 Content (weight) decreased by 1.3%.

Embodiment 2

[0043] Example 2: Using iron ore concentrate with excellent consolidation performance, the weight ratio of organic binder to carrier sulfuric acid slag is 6:94, and 1.0% (weight) carrier binder is added (the amount of organic binder is 0.06%) Instead of 2.5% bentonite, a wet grinding process is adopted, the moisture content of the mixture before the wet grinding is 6.5% (weight), the preheating temperature is 980° C., and the roasting temperature is 1250° C. The pellet indicators are: the drop strength of green balls is 6.0 times / (0.5m·piece), the compressive strength is 12.7N / piece, the burst temperature is greater than 600°C, the strength of preheated balls is 497N / piece, and the strength of finished balls is 2675N / piece. Compared with pellets with bentonite as binder, iron grade increased by 1.5%, SiO 2 The content decreased by 1.9% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com