Composition capable of reducing baby pig stress

A composition and technology for piglets, applied in applications, animal feed, animal feed, etc., can solve the problems of destroying the normal flora of the gastrointestinal tract, failing to regulate the health of the intestinal tract, and requiring many raw materials, so as to improve digestion and utilization, Effect of improving digestibility and reducing feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1. Preparation can reduce the powder of piglet stress

[0020] Converted according to enzyme activity, take 500,000 units of neutral protease, 48,000 units of α-medium-temperature amylase, 800,000 units of pectinase, 60 million units of xylanase, 5 million units of cellulase, and 1.5g of vitamin E , Chitooligosaccharide 5g, fructooligosaccharide 10g, citric acid 16g, flavoring agent 931210g, anhydrous glucose to make up to 1000g. Mix chitooligosaccharides, fructooligosaccharides, citric acid, and flavoring agents first to obtain mixture A; use anhydrous glucose to dilute neutral protease, α-medium-temperature amylase, pectinase, xylanase, and fiber Suzyme and mixture A, and then mix all the raw materials and auxiliary materials, and the powder is obtained after mixing evenly.

Embodiment 2

[0021] Example 2. Preparation of a premix for reducing piglet stress

[0022] Converted according to enzyme activity respectively, take 60 million units of neutral protease, 5 million units of α-medium temperature amylase, 60 million units of pectinase, 5 billion units of xylanase, 400 million units of cellulase, vitamin E0.2kg, chitosan oligosaccharide 0.4kg, fructooligosaccharide 2kg, citric acid 2kg, make up to 100kg with distiller's grains that can pass through a 40 mesh sieve after being crushed. Mix chitooligosaccharides, fructooligosaccharides, citric acid, and flavoring agents first to obtain mixture A; dilute neutral protease, α-medium-temperature amylase, pectinase, xylanase, cellulase, and the mixture with distiller's grains A. Then mix all the raw materials and auxiliary materials, and get the premix after mixing evenly.

Embodiment 3

[0023] Example 3. Preparation of a premix for reducing piglet stress

[0024] Converted according to enzyme activity, take 240,000 units of medium temperature amylase, 2.5 million units of neutral protease, 4 million units of pectinase, 600 million units of xylanase, 50 million units of cellulase, 100 g of chitosan oligosaccharide, 200g of fructooligosaccharides and 320g of citric acid are supplemented to 10kg with distiller's grains after crushing through 40 meshes. Mix chitooligosaccharides, fructooligosaccharides, citric acid, and flavoring agents first to obtain mixture A; dilute neutral protease, α-medium-temperature amylase, pectinase, xylanase, cellulase, and the mixture with distiller's grains A, then all the mixture and all remaining distiller's grains are added into the mixer and mixed, and mixed for 50 minutes to obtain final product.

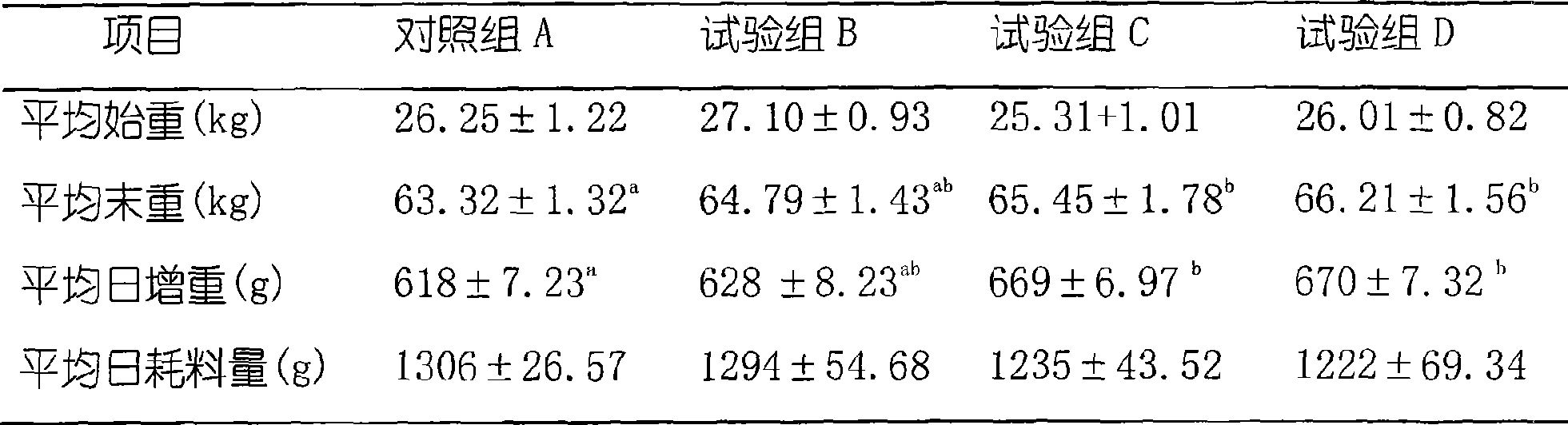

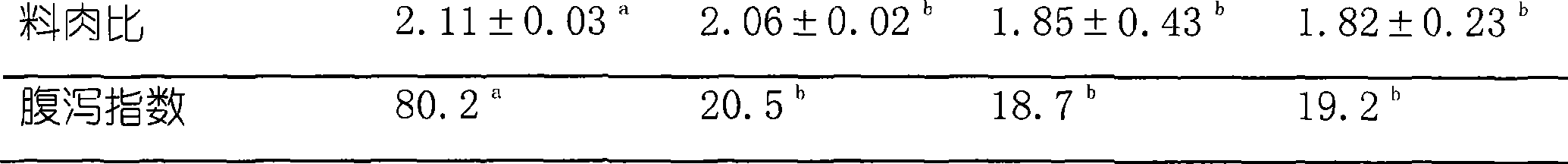

[0025] The invention can comprehensively improve the digestibility of piglets and effectively prevent the occurrence of diarrhea, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com