Method for preparing cellulose water-based solution by stalk

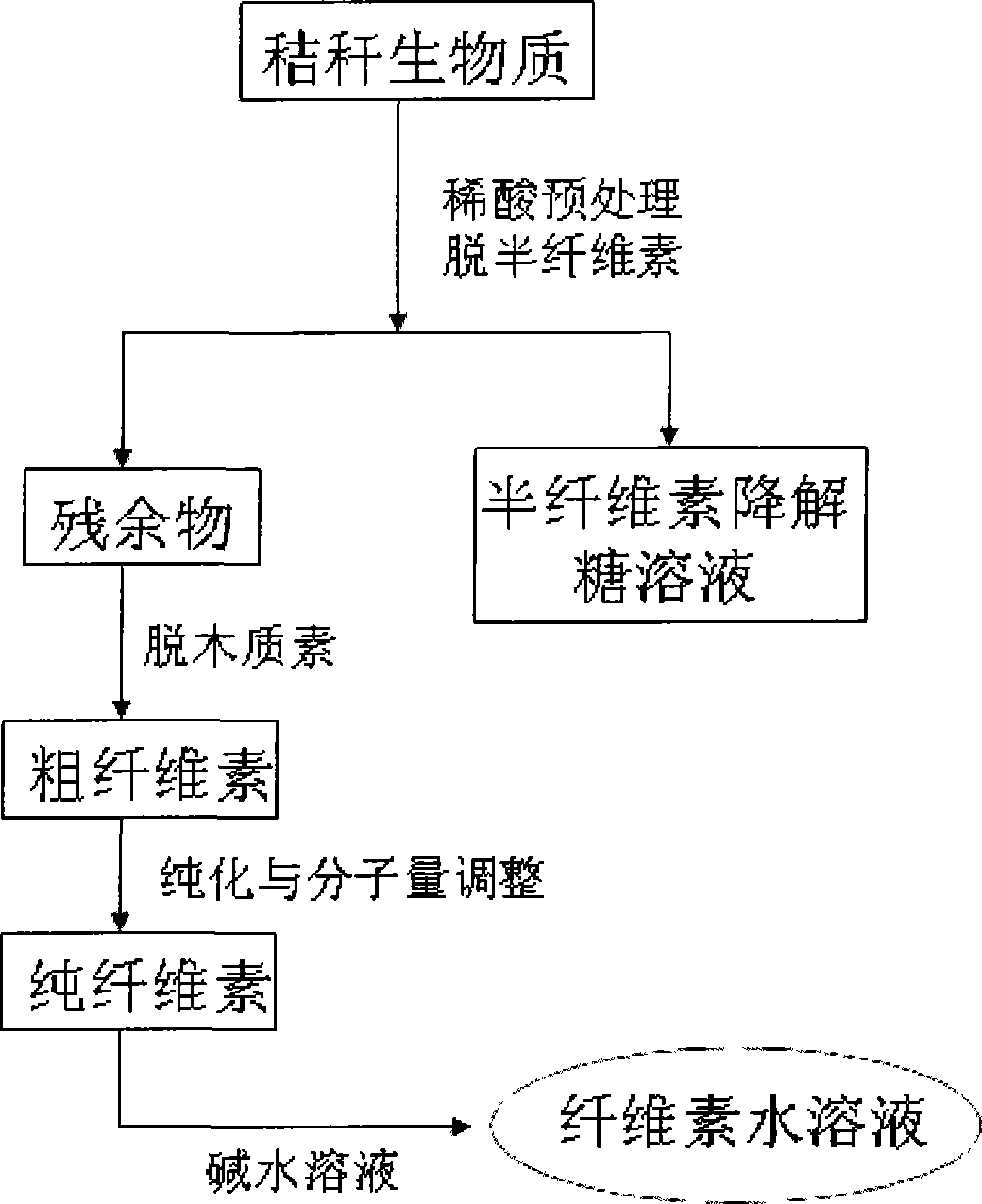

A technology of cellulose and crude cellulose, which is applied in the field of chemical separation, can solve the problems of single source of cellulose, achieve the effect of overcoming single raw material, reducing black liquor, and being conducive to the full utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 9.79 g of dewaxed wheat straw powder was added into the reactor, and then 100 ml of aqueous hydrochloric acid solution with a concentration of 2 mol / L was added, and then reacted at 100° C. for three hours. After cooling, filter and wash the filter cake with deionized water. Then it was added into 100 ml of 3.0% aqueous sodium hydroxide solution, and reacted at 100° C. for three hours. Then filter and wash. The filter cake was added to a mixed aqueous solution of 3.0% hydrogen peroxide and 5.0% acetic acid, and reacted at 60° C. for one hour. The obtained residue was washed and dried to obtain cellulose powder.

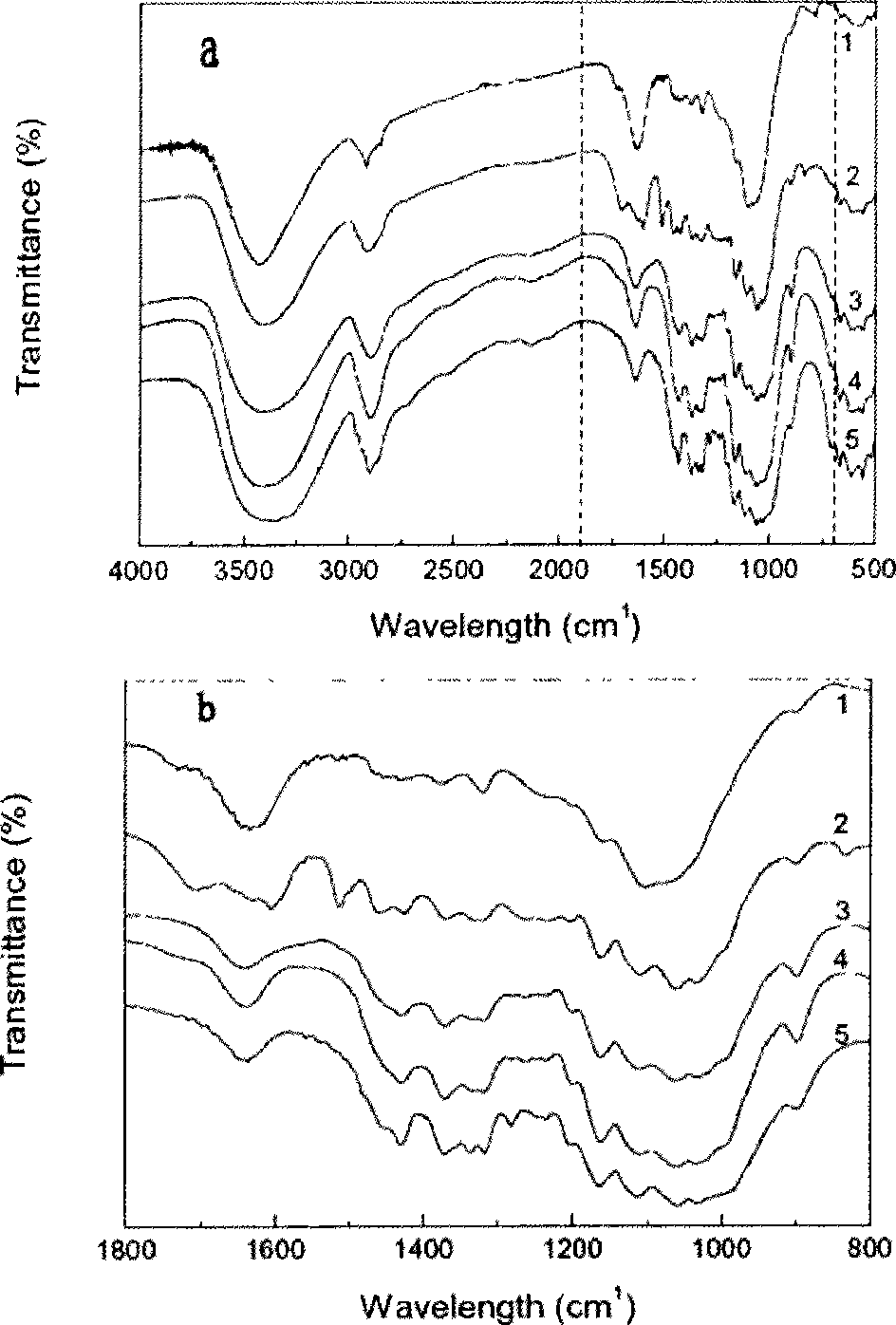

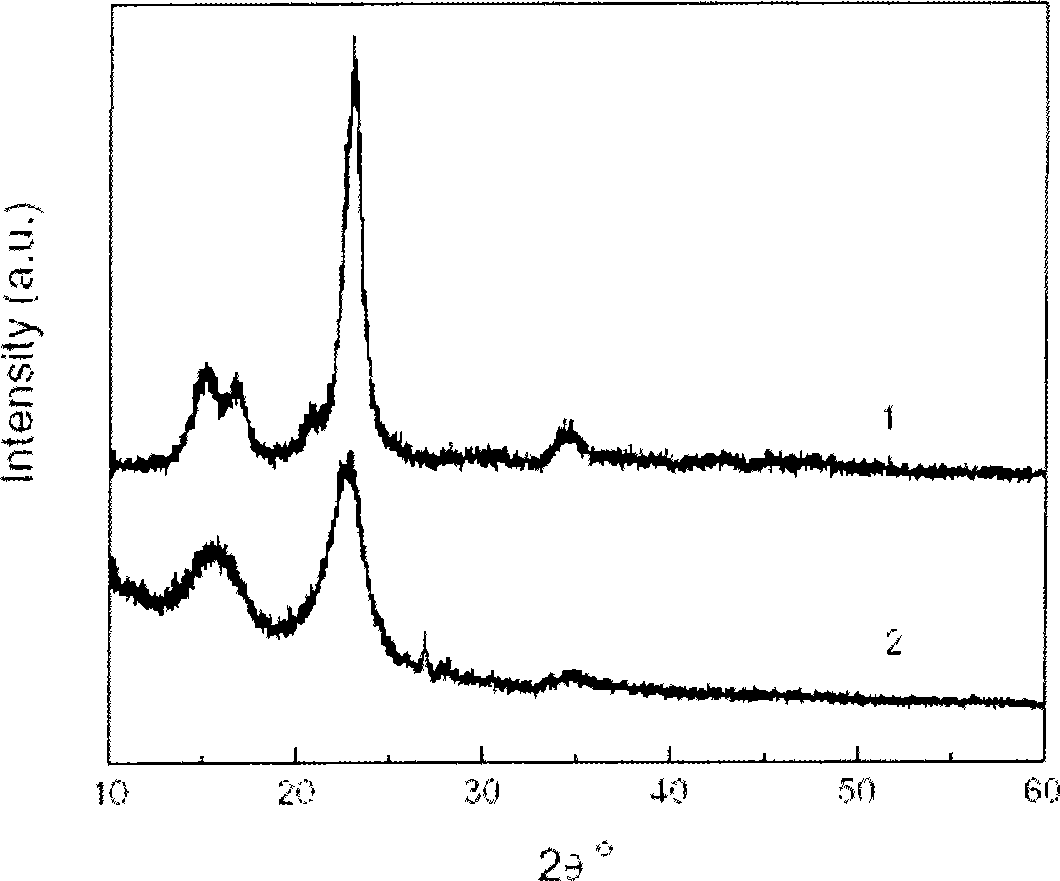

[0033] figure 2 Shown is the FT-IR spectrum of the obtained cellulose, and the IR spectra of straw raw material, different processing stages and pure cellulose are also given on this figure for comparison. It can be seen that the characteristic vibration absorption of cellulose, hemicellulose and lignin exists in the infrared spectrum of straw raw material...

Embodiment 2

[0037] Take 20 grams of dewaxed and dried bagasse, add it into 20 milliliters of 2 mol / liter hydrochloric acid aqueous solution, and react at 100° C. for 3 hours. After cooling, filter and wash to obtain residue I. The residue was added to 200 ml of 3% aqueous sodium hydroxide solution and reacted at 100°C for 2 hours. After cooling, filtration and washing afforded residue II. The residue II was added to 30 ml of 3% aqueous hydrogen peroxide to react for 1 hour. After drying, pure cellulose was obtained with a molecular weight of 32×10 4 g / mol. Add dry cellulose to 1-3M hydrochloric acid aqueous solution, react at 20-50 degrees for 2-4 hours, then filter and wash to obtain pure cellulose with molecular weight adjustment, and its viscosity-average molecular weight ranges from 8×10 4 -20×10 4 Between g / mol.

[0038] Add the obtained cellulose to the lithium hydroxide / urea (or thiourea) complex aqueous solution, stir for 30 minutes, put it in a refrigerator at -20°C for 12 ...

Embodiment 3

[0040] Dried rice straw powder was extracted with toluene-ethanol (2:1, v / v) in a Soxhlet extractor for 6 hours for dewaxing. Afterwards, 10 grams of dried samples were added to 250 milliliters of 3% hydrochloric acid aqueous solution, and reacted at 100° C. for 5 hours. Filter, wash with deionized water and ethanol until neutral, and then dry at 50°C to obtain residue I. The resulting residue I was added to 5% aqueous sodium hydroxide solution and reacted at 100°C for 3 hours, filtered and washed with deionized water and ethanol to neutrality, and dried at 50°C to obtain residue II.

[0041] The obtained residue II was suspended in 2 mol / L dilute hydrochloric acid, and hydrolyzed at room temperature for 2 hours to obtain a degraded cellulose sample. Its viscosity average molecular weight ranges from 12×10 4 -38×10 4 Between g / mol.

[0042] Add the obtained cellulose to the lithium hydroxide / urea (or thiourea) complex aqueous solution, stir for 30 minutes, put it in a refr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com