Perofskite structure lanthanide manganese oxides/tin oxide heterogeneous p-n junction and preparation thereof

A perovskite structure, manganese oxide technology, applied in the field of material manufacturing, can solve problems such as hindering the application of perovskite structure oxide p-n junction, high price of high-power lasers, and increasing the cost of PLD methods, and achieve excellent rectification characteristics, Good adhesion and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Deposit 300nm thick SnO on the substrate single crystal Si(100) by magnetron sputtering 2 Layer, deposition conditions: magnetron sputtering RF power 100W, SnO 2 Ceramic is the target material, the substrate temperature is 500°C, the working gas is argon and oxygen, the working pressure is 0.7Pa, and the oxygen partial pressure is 10%;

[0022] 2) SnO obtained in step 1) by magnetron sputtering 2 A 150nm-thick LSMO layer is deposited on the layer to obtain a perovskite structure lanthanum manganese oxide / tin oxide heterogeneous p-n junction. Deposition conditions: magnetron sputtering RF power of 100W, LSMO ceramics as target material, and substrate temperature of 800 ℃, the working gas is argon and oxygen, the working pressure is 1.5Pa, and the oxygen partial pressure is 20%.

Embodiment 2

[0024] 1) Using magnetron sputtering method on the substrate single crystal TiO 2 Deposit 100nm thick SnO on (100) 2 Layer, deposition conditions: magnetron sputtering RF power 200W, SnO 2 Ceramic is the target material, the substrate temperature is 300°C, the working gas is argon and oxygen, the working pressure is 0.5Pa, and the oxygen partial pressure is 15%;

[0025] 2) SnO obtained in step 1) by magnetron sputtering 2 A 300nm-thick LSMO layer is deposited on the layer to obtain a perovskite structure lanthanum manganese oxide / tin oxide heterogeneous p-n junction. Deposition conditions: magnetron sputtering RF power of 200W, LSMO ceramics as target material, and substrate temperature of 600 ℃, the working gas is argon and oxygen, the working pressure is 0.5Pa, and the oxygen partial pressure is 25%.

Embodiment 3

[0027] 1) Using magnetron sputtering method on the substrate single crystal ZnF 2 Deposit 200nm thick SnO on (100) 2 Layer, deposition conditions: magnetron sputtering RF power 150W, SnO 2 Ceramic is the target material, the substrate temperature is 600°C, the working gas is argon and oxygen, the working pressure is 1Pa, and the oxygen partial pressure is 5%;

[0028] 2) SnO obtained in step 1) by magnetron sputtering 2 A 100nm-thick LSMO layer is deposited on the layer to obtain a perovskite structure lanthanum manganese oxide / tin oxide heterogeneous p-n junction. Deposition conditions: magnetron sputtering RF power of 150W, LSMO ceramics as target material, and substrate temperature of 750 ℃, the working gas is argon and oxygen, the working pressure is 1Pa, and the oxygen partial pressure is 5%.

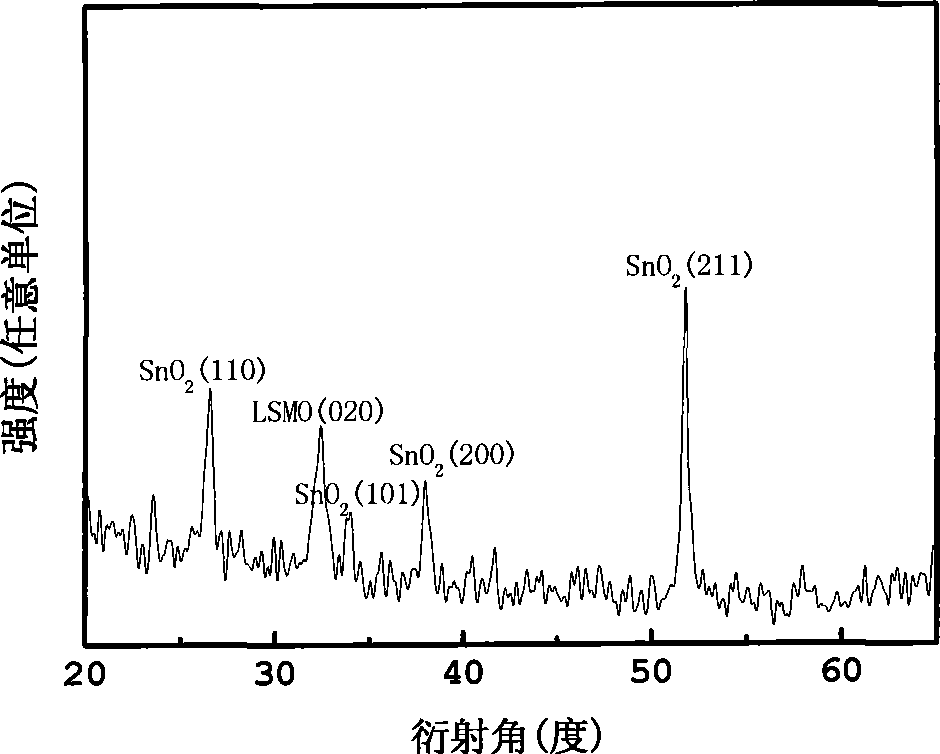

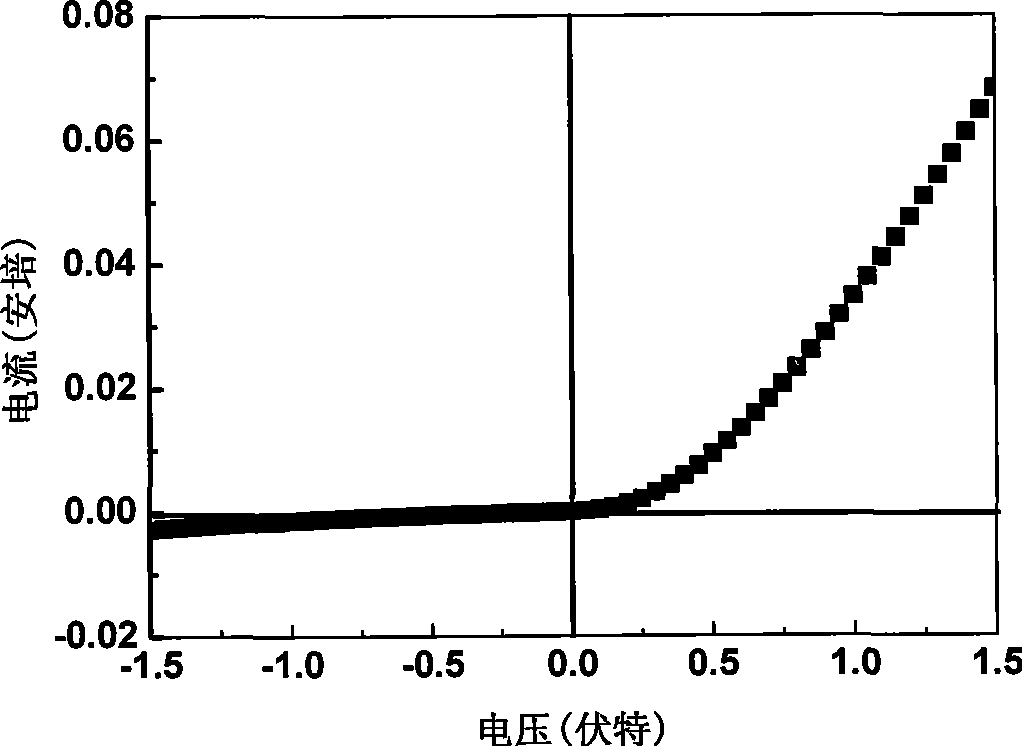

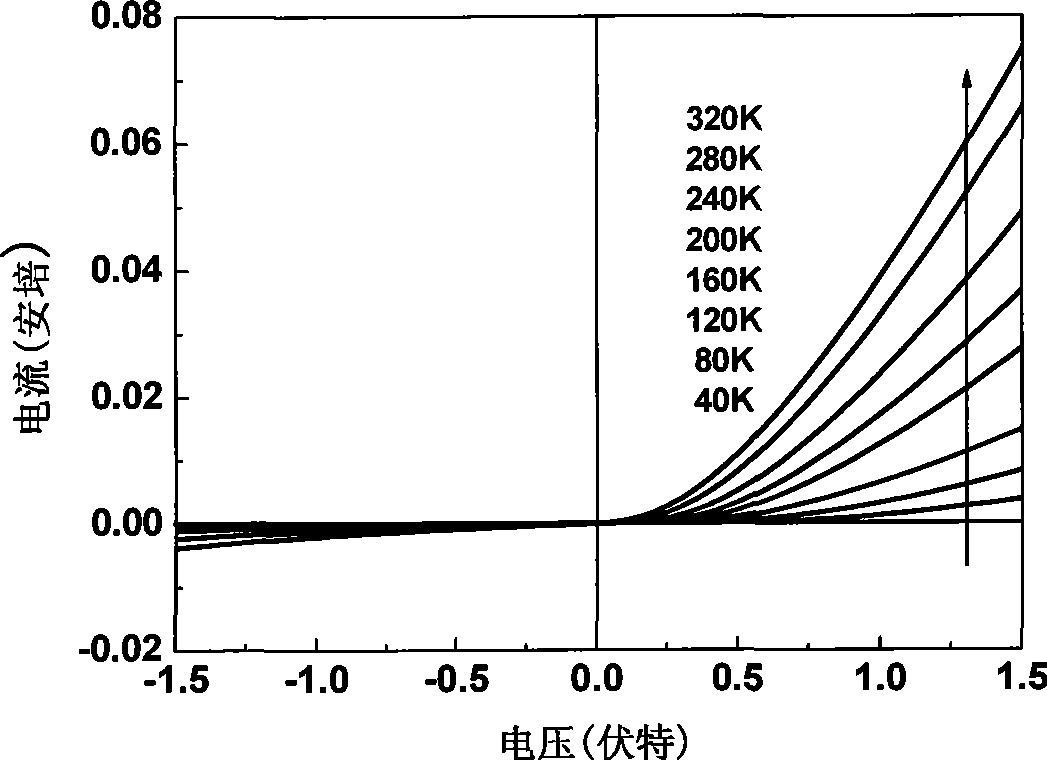

[0029] From figure 2 It can be seen that the SnO prepared by the present invention 2 The / LSMO p-n junction exhibits good rectification characteristics at room temperature (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com